Research Partners 3D Print MIM Tool With Near-Contour Cooling

Compared to a conventional approach in machining, the use of an additive manufacturing process to produce a MIM tool reduces the total production time from around 8 weeks to approximately 5 days.

Share

Read Next

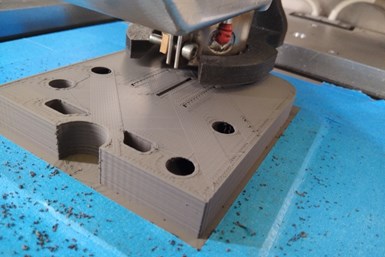

A 3D tool for metal injection molding being produced on an ExAM 255. Photo Credit: AIM3D GmbH, Rostock

A joint research project of the University of Rostock and Stenzel MIM Technik GmbH resulted in the printing of a 3D metal injection molding (MIM) tool with near-contour cooling and greatly reduced production time. Compared to a conventional approach in machining, the use of an additive manufacturing (AM) process to produce a MIM tool reduces the total production time from around 8 weeks to approximately 5 days.

The basis of the project was the use of AIM3D’s CEM technology with an ExAM 255 system, which is an all-in-one, multimaterial 3D printer for AM of metals, plastics and ceramics. The system combines a high precision of 3D components with high build speeds for AM.

As part of a project funded by the German Federal Ministry for Economic Affairs and Energy (BMWi), the 3D printed MIM tool is a cooperative development between the Chair of Microfluidics (LFM) at the University of Rostock and Stenzel MIM Technik GmbH. The basis for the process and application is the use of the CEM technology from AIM3D, implemented on an ExAM 255 system.

The project goal was to use 3D printing to manufacture a tool for metal injection molding with near-contour cooling. In 3D printing, near-contour cooling can be incorporated as a so-called functional integration with helical channels directly in the tool. In other words, it is not embedded as inlets, as is the case with larger tools.

The goal of any near-contour cooling of injection molds made out of metals or polymers is to significantly reduce the cycle time. The principle of near-contour cooling is to guide coolant fluids through near-contour cooling channels with low cross sections. They cool the component already during the cycle. This leads to a faster demolding process, which significantly shortens the cycle. The complex geometry of the helical cooling channels is created with the help of CAD technology using simulation models that are based on the “needs” of the component. According to the project team, long-term experience shows a reduction in cycle time by around 20%, depending on wall thickness and size.

As an integrated component solution, 3D printing offers the advantage of a “one-shot technique” as a functional integration compared to mold-bound processes. The application example therefore demonstrates an opportunity to drastically reduce the time to market.

The aim of the cooperation project is to develop a new process chain for the cost-efficient and rapid production of MIM tools. Up until now, time periods of up to eight weeks have been needed to produce a conventional metal injection mold. With 3D metal printing, that time can be reduced to about five days.

As part of the cooperation, an optimized 3D model of the tool was initially developed using CAD and simulation tools. This data was then transferred to the ExAM 255 CEM system, together with the necessary process parameters. A so-called green part is then 3D printed. Afterward, the part is sintered in a multistage process to produce the final material properties.

With this process, complex metallic components can be rapidly produced after the necessary debinding and sintering steps. At the same time, the CEM process enables the control of the volumetric shrinkage associated with sintering. The resulting mold has a cavity. The component consists of a thick-walled part with thin fins. These fins cannot be produced without near-contour cooling, as they are difficult to demold. Stenzel MIM Technik hopes to achieve a significant reduction in cycle time for this component by up to 70-80%. However, injection molding trials for testing are still pending.

The multimaterial 3D printer ExAM 255 can be used with a variety of different materials (metals, plastics, ceramics) and with various processes (hybrid components). Compared to powder bed processes or even other 3D printing processes that use filaments, systems using the CEM process achieve tensile strengths that come close to classic thermoplastic, mold-bound injection molding. Researchers say the cost advantage of 3D printing is particularly striking when commercially available granulates are used instead of filaments. When granulates are used, the CEM process leads to cost savings of up to a factor of 10.

Related Content

Video: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More