Metal

The Case for Tackling the Toughest Material First

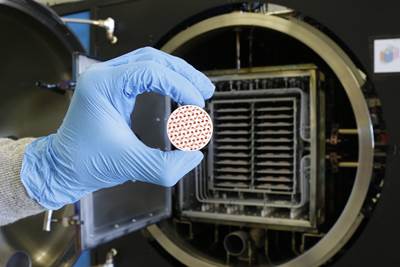

The increasing speed and power of high-end processors and data centers has created a market for advanced thermal management solutions. A Silicon Valley startup called Holo is dedicating its first line of products toward this market, starting with 3D-printed copper heat exchangers.

Read MoreVelo3D Partners with GoEngineer for Sales and Service Support

GoEngineer will be Velo3D’s largest partner in the U.S., while Velo3D’s other existing sales networks and direct purchase opportunities remain in place.

Read MoreDesktopMetal Introduces Pure Copper for its Studio System

Unlike laser-based processes (which often print chromium zirconium copper), the Studio System’s Bound Metal Deposition process is able to print pure copper, unlocking the full benefits of the material.

Read MoreVideo: Programming for Additive Turning of Cylindrical Parts

Directed energy deposition while the part is spinning enables a means of 3D printing axially symmetric parts. The operation is like CNC turning with material added instead of machined. Open Mind discusses programming the machine paths for this type of build.

WatchGM Opens Additive Industrialization Center Dedicated to 3D Printing

3D printing will help transform GM operations in product development, motorsports and manufacturing.

Read More3D Printing and the Next Giant Leap for Mankind

A collaboration between Aerojet Rocketdyne and NASA is resulting in critical parts being 3D printed for new versions of the workhorse RS-25 engine.

Read MoreDesktop Metal to Acquire EnvisionTec

Acquisition expands Desktop Metal’s product portfolio across metals, composites and polymers.

Read MoreDesktop Metal Delivers Mid-Volume Metal 3D Printing System

Shop System is said to achieve exceptional surface finish parts with rich feature detail at speeds up to 10 times faster than those of legacy 3D powder bed fusion technologies.

Read MoreSpeed Is Relative in AM: A Data-Driven Comparison of Multi-Laser Powder Bed Fusion and Binder Jet Processing

There is a difference between the effective print speed and the actual cost to produce the component with AM. John Barnes compares binder jet processing with powder bed fusion for metal parts.

Read MoreAMGTA Publishes First Research Paper on Sustainability in Additive Manufacturing

Systematic review highlights importance of component end use and need for more research.

Read More