Metal

Material Innovation Is a Powerful Freedom of AM: Here Are Examples

Possibilities that were speculative a few years ago are coming true today. Applications of metal matrix composite provide an example. Recent articles explore the ongoing advance of 3D printed materials.

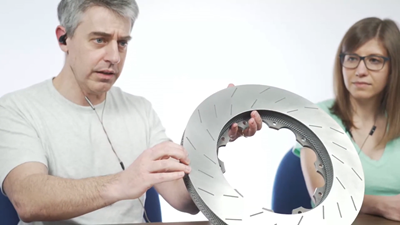

Read MoreMetal Additive Manufacturing on the Track

Additive manufacturing and topology optimization are helping teams produce stronger, lighter parts that meet the demands of off-road racing vehicles.

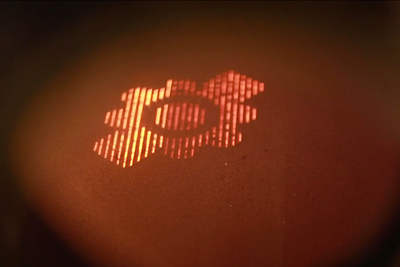

Read MoreNeuBeam 3D Printing Process Is an Update for Electron Beam Melting

The recently introduced Calibur3 system from Wayland Additive overcomes challenges to bring new materials and capabilities to EBM metal 3D printing.

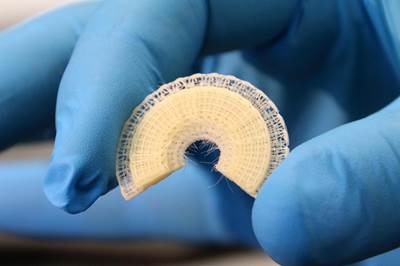

Read MoreReusable, 3D Printed Copper Filter: The Cool Parts Show #28

In this episode of The Cool Parts Show, we learn how controlled porosity obtained through binder jetting can be applied to build metal filters capable of trapping — and even eliminating — virus particles.

WatchCollaborators Publish Overview of Disposal Procedures for Powder Condensate

Sintavia partners with the AMGTA and Triumvirate Environmental Inc. to publish overview of proper handling procedures for powder condensate waste generated as part of the PBF additive manufacturing process.

Read MoreSolukon Digital Factory Tool Integrates AM Automation, Quality Assurance

System is designed to increase efficiency and ensure continuous quality control in additive manufacturing.

Read MoreDesktop Metal Launches Desktop Health for Patient-Specific Solutions

Health care business leverages Desktop Metal’s portfolio of AM solutions for current and future applications spanning dentistry, orthodontics, dermatology, orthopedics, cardiology, plastic surgery, and printed regenerative tissues and grafts.

Read MoreMetal 3D Printed Part Has Unplanned Feature, Not Part of the Design — AM: Why the Failure? #2

This component for the oil and gas industry features a shelf through the lattice structure that does not appear in the CAD model. How did it get there? The answer does not involve STL, but we talk about that anyway.

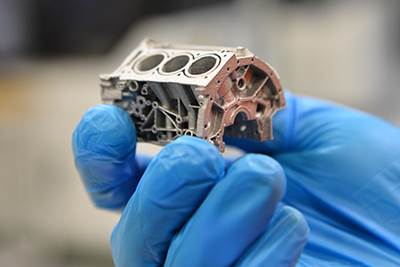

WatchExOne, Ford Motor Co. Develop Aluminum Binding Jetting Process

This aluminum engine block model, 3D printed in 6061, demonstrates the high resolution and geometric control that can be produced in a new binder jet 3D printing and sintering process developed by Ford and ExOne.

Read MoreDesktop Metal, Uniformity Labs Develop Fully Dense, Sinterable Aluminum

Uniformity 6061 aluminum will be available exclusively to Desktop Metal customers as part of its ongoing partnership with Uniformity Labs.

Read More