Desktop Metal Delivers Mid-Volume Metal 3D Printing System

Shop System is said to achieve exceptional surface finish parts with rich feature detail at speeds up to 10 times faster than those of legacy 3D powder bed fusion technologies.

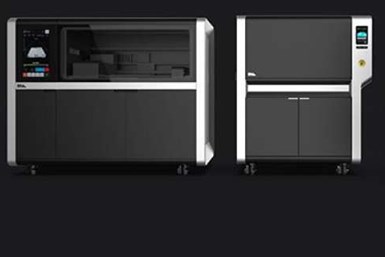

Desktop Metal’s Shop System offers high-quality binder jetting to an entirely new market of machine shops, casting foundries and powder metal component suppliers.

Desktop Metal’s Shop System is a metal binder jetting system that is designed to enable affordable, batch production of high-quality metal parts. This turnkey metal additive manufacturing (AM) solution is said to achieve exceptional surface finish parts with rich feature detail at speeds up to 10 times faster than those of legacy 3D powder bed fusion (PBF) technologies.

According to the company, the Shop System offers a high-resolution, mid-volume production solution with its high-speed, single-pass print engine, and eliminates many of the constraints imposed by traditional manufacturing methods. It is said to offer reliable production of serial batches of complex, end-use metal parts in a fraction of the time and cost of conventional manufacturing and comparably priced AM technologies.

Featuring a high-resolution, advanced print engine, the system is a complete end-to-end solution that includes a single-pass, binder jetting printer; a drying oven for hardening green parts prior to depowdering; a powder station for depowdering parts with built-in powder recycling; Desktop Metal’s furnace designed for accessible, industrial-strength sintering; and integrated powder handling accessories and workflow. This turnkey solution can seamlessly integrate with existing shop operations.

The system features an easy-to-use software interface, as well as engineered powders and processing parameters optimized for use with the system to deliver exceptional quality and ensure repeatability. It also offers high productivity with speeds up to 800 cc/hour at 75-micron layer thickness, enabling batches of tens or hundreds of complex printed parts in as little as five hours. Customers can use the system to print dense, complex parts with incredibly fine feature detail and surface finishes as low as four-micron roughness average (Ra) out of the furnace due to the Shop System's high-resolution printhead - made possible through droplet sizes as small as 1.2pL, with drop multiplexing up to 6pL.

Related Content

-

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

-

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

-

Quadrus: Powder Management Tactics for Tungsten Rhenium and Other AM Alloys

The expert in additive manufacturing of high-value parts for the Defense Department often must change from one exotic material to another in its powder bed machines. Cleaning is a core competency. Here are lessons of this company’s system for working with an ever-changing mix of 3D printed alloys.