Metal

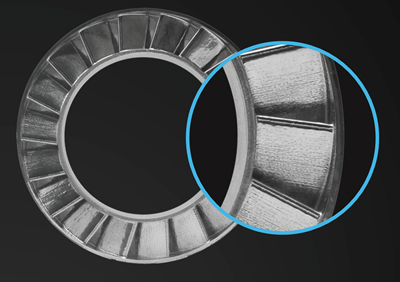

26 Steps Vs. 9: The Metal AM Case for Mission Critical Parts

Knust Godwin introduced metal AM into its precision-machining environment nearly eight years ago. Now the company is using the capability to break through into new applications and give 3D printed mission-critical parts a renewed business case.

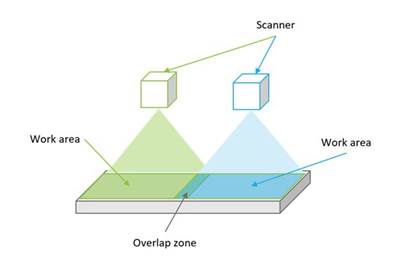

Read MoreA Technical Economic Perspective on Multi-Laser Powder Bed Fusion 3D Printers

When it comes to laser-based powder bed fusion, more lasers do not always lead to greater productivity. Considerations for multi-laser 3D printing.

Read MoreOqton FactoryOS Integrates EOS Software for Seamless Workflows

Deep software integration enables a tight connection of manufacturing software and hardware that supports efficient, end-to-end production workflows on EOS systems.

Read MoreDesktop Metal’s Live Sinter Software Eliminates Trial and Error

Sintering process simulation software corrects for shrinkage and distortion of binder jet 3D printed parts during sintering to minimize trial and error.

Read MoreWith This 3D Printed Block, EBM Is an Aid to CNC Machining

Holding the part is a challenge of machining for additive manufacturing. This medical manufacturer prints fixture tooling tailored to its additive parts.

Read MoreAddUp Moves North American HQs to Cincinnati Area

The U.S. subsidiary of AddUp is moving its North American headquarters to Blue Ash, Ohio, at the current location of AddUp’s other U.S. subsidiary, BeAM Inc.

Read MoreSLM Solutions' NXG XII 600 Enables High-Volume Production

Machine features 12 lasers designed to use in serial production for high-volume applications as well as for printing large parts.

Read MoreAlloyed Formalizes Company Name Change

New corporation brings together the technology of Alloys-By-Design, Betatype and Alloyed Digital Manufacture to provide solutions for optimizing advanced digital metal manufacturing applications.

Read MoreWhat's the Big Idea in Additive Manufacturing?

A new series presented by Additive Manufacturing Media tackles important themes AM is touching that promise to change manufacturing in a big way.

Read MoreFor EBM Implant Manufacturer, Growth Is Built into the Plan

Amplify Additive needs to be small today. A close, nimble team can innovate quickly and realize the promise of additive manufacturing for orthopedic implants. Yet the company needs to be bigger soon, because success will lead to scalable production.

Read More