Lightweighting

3D Printed Tennis Racket Serves a Collaborative Win

The collaboration between All Design Lab and Protolabs led to the creation of a 3D printed tennis racket via direct metal laser sintering, called Hìtëkw. This project not only pushed the limits of additive in terms of design capabilities but revealed how important active communication between customer and manufacturer can be for a project’s success.

Read MoreSidus Space Successfully Launches LizzieSat Hybrid 3D-Printed Satellite

The hybrid 3D-printed satellite was manufactured using Markforged 3D printers for parts that would be incredibly lightweight, durable and custom to the structure to ensure the satellite remains intact during launch and works properly for its full life span in space.

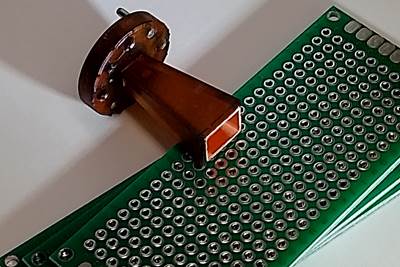

Read MoreHorizon Demonstrates Effectiveness of HMT-Metal Coating Process for Plastic Micro Additive Manufacturing Parts

The ability to make mm-wave components via micro-additive manufacturing enables the production of smaller and lighter weight components, and also opens up the possibility of making them with properties and geometric features impossible using alternative fabrication processes.

Read MoreSpherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read MoreTitanium Golf Club Line Leverages AM to Boost Clubhead Performance

Japanese lifestyle golf brand Designer utilizes Farsoon 3D printing to optimize the design and production of its latest titanium golf club line.

Read MoreLithoz, ORNL Partner to Advance Processing for High-Temperature Ceramics

The new process could enable laser slurry drying of non-oxide ceramics with high refractive indexes

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreAmerica Makes Awards $3.2M for Delta Qual Project Winners

The project call winners are tasked with creating qualified additive manufacturing (AM) processes that offer rapid and affordable flexibility in crucial processes, postprocessing and material feedstock variables, while efficiently validating a qualified AM material through statistical analysis.

Read More3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

WatchThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Watch