Titanium Golf Club Line Leverages AM to Boost Clubhead Performance

Japanese lifestyle golf brand Designer utilizes Farsoon 3D printing to optimize the design and production of its latest titanium golf club line.

Sporting enthusiasts are always looking for an edge to take their play to the next level. For golfers, that edge may now literally and figuratively come in the form of additive manufacturing (AM).

There are many little tricks and tips to improve a golfer’s game. But one of the best ways to immediately see an improvement is to get better (or the right) equipment. A particular golfer might need a longer putter, bigger driver or even lighter clubs.

Japanese lifestyle golf brand Designer was looking for its own creative edge when it began utilizing laser powder bed fusion, specifically Farsoon’s dual-laser FS200M metal 3D printing system, to create its Titanium Golf Club Line. According to the company, the

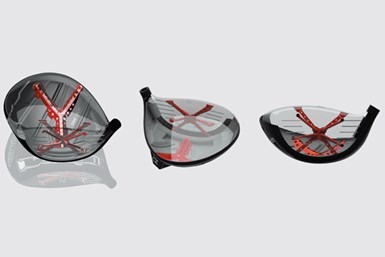

Use of metal 3D printing enables Designer to innovate, design and produce clubheads for players seeking improved performance in distance, accuracy and stability with greater forgiveness. Novel features of the club made possible through 3D printing in a strong, lightweight titanium alloy include a design with self-supported internal structures, and a high-speed impact surface engineered for ductility and strength for the perfect strike. Performing design, development and series production on the dual-laser system is said to result in design-through-manufacturing cost per clubhead savings of about 70% compared to the golf club maker’s conventional processes. A multilayer thickness parameter aids productivity in production.

One-Piece Production, Improved Precision

Assembly consolidation is part of this savings. A typical clubhead geometry includes toe, face, sole, crown, heel and hosel. With Farsoon’s metal 3D printing, the clubhead can be produced in one piece, with improved precision and performance compared to the conventional club. The integrated structure offers greater resistance to twisting, and increased stability and driving distance for the player.

Streamlining Geometries

The company says the 3D printed Designer clubheads include many aerodynamic features to enable wind to flow faster and smoother over the integrated geometry, thereby reducing drag and increasing both head stability and speed. A distinctive “sound window” design is said to offer a more pleasant sound on impact.

Related Content

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read MorePowderCleanse Concept Delivers In Situ Powder Analysis for Metal 3D Printing

A collaborative project developed a prototype solution for measuring particle size distribution on the production floor, as part of the sieving step typical to additive manufacturing processes using metal powders.

Read MoreFaster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More