Lightweighting

Generative Design Improves Micromobility FUV: The Cool Parts Show #19

Arcimoto’s lightweight “Fun Utility Vehicle” gets even lighter thanks to parts that could only come from additive manufacturing. On this episode of The Cool Parts Show, some of the craziest automotive parts you have seen.

WatchGenerative Design to Bring Weight and Cost Savings for Micromobility FUV

The “Fun Utility Vehicle” from Arcimoto is already in production, and already lightweight. But after just 30 days of redesign for additive manufacturing, the company discovered major components could be made lighter still, and production could be made simpler.

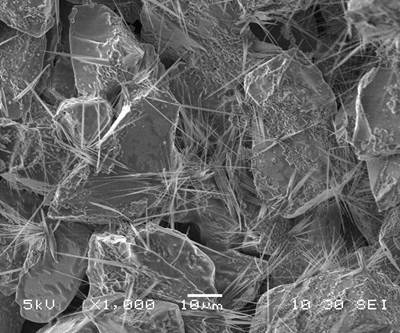

Read MoreAre Crystals the Key to 3D Printing with Silicon Carbide?

If SiC was easier and cheaper to apply, we would find many more uses for this hard, lightweight ceramic. Researchers have found a promising additive manufacturing approach, with crystal growth as the bonding mechanism.

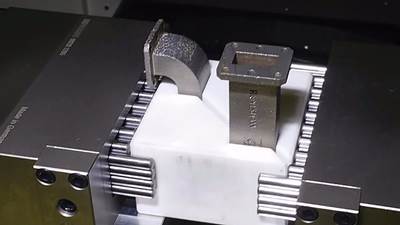

Read MoreLightweight Sandvik Cutting Tool Employing Topology Optimization Now Available

Additive manufacturing aids “subtractive” CNC machining. We first saw this tool in an early version last year. See the video in this post.

WatchGM Seat Bracket Made with Autodesk Generative Design Software

The bracket is the result of a multi-year alliance between the two companies to explore generative design, AM and materials science for vehicle lightweighting.

Read MoreAltair Releases Inspire2018 Simulation-Driven Design Software

The software enables rapid simulation, gives insight into lightweighting, and can be used by businesses with little or no simulation experience.

Read MoreLightweighting with Lattices

Building components as a network of unit cells may improve material utilization and performance.

Read MoreXact Metal Launches Industrial-Grade XM300 Metal 3D Printer

A lightweight, high-speed gantry is key to the powder-bed fusion system’s speed.

Read MoreMeeting the Machining Challenges of Additive Manufacturing

You can 3D print the part, but can you finish it? Here is how to overcome the challenge of part deflection in the machining of lightweight, complex AM parts.

Read MoreWindform Composite 3D Printing Materials Enable Lightweight, Flexible Air Inlet

CRP Technology recently developed a new front air inlet for a Moto3 racing customer, which was manufactured in Windform materials by using an SLS additive manufacturing technique.

Read More