Horizon Demonstrates Effectiveness of HMT-Metal Coating Process for Plastic Micro Additive Manufacturing Parts

The ability to make mm-wave components via micro-additive manufacturing enables the production of smaller and lighter weight components, and also opens up the possibility of making them with properties and geometric features impossible using alternative fabrication processes.

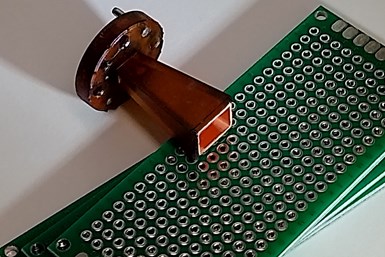

Horn antenna made via micro-AM and coated in Horizon’s copper coating. Source: Horizon Microtechnologies

Horizon Microtechnologies has completed its rigorous functional testing to prove the effectiveness of its HMT-Metal coating process for making high-frequency D-Band horn antenna via 3D printing.

The company says it was founded on the understanding that microscale manufacturing using micro-additive manufacturing (AM) technologies would be optimized through the integration of a number of technologies and processes. Building on the ability of today’s micro-AM technologies to build precise parts with micron-level tolerances repeatably, Horizon’s proprietary coating technologies successfully expands the functionality of parts which are typically produced in plastics on commercially available micro-AM platforms.

“The work on the high-frequency D-band horn antenna used our HMT-Metal coating process with which copper layers can be applied very evenly and conformally to a variety of component shapes and materials,” says Andreas Frölich, Horizon CEO. “From a commercial perspective, such components fit well with the use of micro-AM as they are typically in the cm size range, with sub-mm dimensions, and require the attainment of micron tolerances. The market demands such antenna and other mm-wave components to exhibit higher frequencies and connectivity for use in industrial measurement technology, sensor technology and communication applications with very low latencies.”

Being able to make such mm-wave components via micro-AM enables the production of smaller and lighter weight components, and also opens up the possibility of making them with properties and geometric features impossible using alternative fabrication processes.

The performance of an antenna depends on a large number of component properties that are difficult to measure and calculate directly such as the conductivity of the metallic layers, layer thicknesses, layer thickness homogeneity, dimensional accuracy of the antenna and surface roughness. Instead of an elaborate determination of all these properties, Horizon undertook a functional comparison of its copper coated micro-AM produced horn antenna with a traditionally produced commercially available antenna, a pragmatic approach which enabled Horizon to prove its manufacturing technology is sufficiently good to serve high frequency and antenna applications.

Measurements were made of the radiation pattern (how much signal goes out of the antenna and in which direction) and the so-called S11 parameter (how much of the signal is reflected back from the antenna into the transmitter). The directivity of the antenna (how much signal goes in the forward direction) and the S11 parameter can be compared clearly and directly with traditionally produced antennas, and the test showed that the Horizon antenna had approximately the same directivity and a better S11 parameter.

“Successful testing should indicate a high gain value in the forward direction and as little back reflection as possible. We are delighted to say that after testing, our micro-AM copper coated horn antenna performed as well as a conventionally built horn antenna, removing many of the reservations that 3D printed devices are often faced with,” Frölich says. “This opens up some very interesting opportunities as companies requiring horn antennas and other mm-wave components can now exploit the process advantages of micro-AM by partnering with Horizon as their development and manufacturing partner.”

Frölich says the company didn’t even perform full-blown dedicated additive design-thinking efforts for the antenna because it wanted to fabricate something emulating the conventional counterpart. “Yet we have an antenna that weighs only a sixth of its conventional counterpart and takes up 15% less space,” Frölich adds. “This is a powerful indication of the kind of benefits that dedicated AM-based component design-thinking could achieve.”

Related Content

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreNanoOne Green 3D Printer Offers Increased Precision, Ability to Work With Broad Range of Materials

Formnext 2024: The printer features UpNano’s adaptive resolution technology, which dynamically expands the width of the laser beam tenfold to speed up printing in bulk material areas or shrinks it where precision is needed.

Read MoreHorizon Expands Services With Subcontract Micro AM Production, Design Support

Horizon also offers a suite of proprietary coating processes that enable customers to successfully expand the functionality of parts which are typically produced in plastics on commercially available micro additive manufacturing platforms.

Read MoreHorizon Microtechnologies’ Micro AM for Conductive, Environmentally Resistant Parts

The company has developed a template-based 3D microfabrication technology that gives manufacturers the ability to add conductivity to all or selected parts of a 3D-microfabricated template.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More