Sidus Space Successfully Launches LizzieSat Hybrid 3D-Printed Satellite

The hybrid 3D-printed satellite was manufactured using Markforged 3D printers for parts that would be incredibly lightweight, durable and custom to the structure to ensure the satellite remains intact during launch and works properly for its full life span in space.

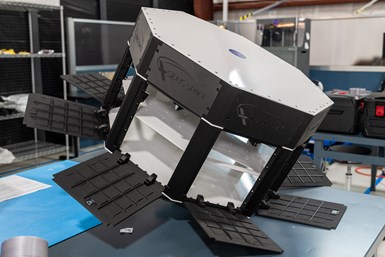

Sidus Space has utilized Markforged 3D printers to fabricate components quickly and effectively for multiple programs, enabling the company to meet customer requirements in a cost-effective and timely manner. Source: Sidus Space

Sidus Space, a multifaceted space and data-as-a-service satellite company, has successfully launched and deployed its LizzieSat satellite to low Earth orbit as part of SpaceX’s Transporter-10 Rideshare mission. Liftoff occurred on March 5 from Space Launch Complex 4 East at Vandenberg Space Force Base in California.

The hybrid 3D-printed satellite was manufactured using Markforged 3D printers for parts that would be incredibly lightweight, durable and custom to the structure to ensure the satellite remains intact during launch and works properly for its full life span in space.

The primary mission of the LizzieSat platform is offering customized intelligence to support various industries, including agriculture (crop health), environmental (assessing deforestation, climate change) and maritime (shipping routes) with its on-orbit satellite technology.

The successful deployment of LizzieSat signifies a monumental achievement for Sidus Space, marking its entrance into the next era of space technology and data services. To rewatch the live mission webcast, visit spacex.com or sidusspace.com.

“We are thrilled to announce the successful launch of our first LizzieSat satellite,” says Carol Craig, Sidus Space founder and CEO. “This accomplishment is a testament to the dedication, expertise and collaboration of our team. LizzieSat epitomizes our commitment to pushing the boundaries of space technology and advancing our mission of Bringing Space Down to Earth.”

Markforged has been a a key player in Sidus’ 3D-printed LizzieSat satellites. “Markforged 3D printers initially played an important role in our successful External Flight Test Platform (EFTP) mission, an on-orbit external experimental facility that was hosted on the NanoRacks International Space Station External Platform (NREP),” Craig says. “Building on the success of our EFTP program, we have continued to leverage Markforged solutions in the development of LizzieSat.”

By utilizing Markforged 3D printers, Sidus Space has been able to fabricate components quickly and effectively for multiple programs, which enables the company to meet customer requirements in a cost-effective and timely manner.

Sidus Space’s LizzieSat multipurpose constellation is designed to meet the precise conditions of commercial and governmental demands in an increasingly interconnected, cloud-based and data-driven world. The LizzieSat platform aims to take advantage of a shift away from static and low-frequency satellite imaging and geospatial solutions toward on-demand access of real-time geospatial intelligence.

LizzieSat is positioned to revolutionize space-based data collection and analysis with its innovative Space Platform with a Purpose and FeatherEdge AI integration. This mission aims to broaden its customer base across military and commercial sectors, offering tailored intelligence solutions for industries such as defense, agriculture, maritime, and oil and gas.

As the LizzieSat mission progresses, Sidus Space says it remains steadfast in its commitment to delivering cutting-edge solutions and pushing the frontiers of space technology and data collection. The company looks forward to upcoming missions, with LizzieSat-2 and LizzieSat-3 expected to launch on future SpaceX Rideshare missions.

To see how Markforged 3D printed a satellite with Sidus Space, watch this video.

“Markforged has been an incredible partner to us over the years,” Craig adds. “We are honored to be highlighted in one of their videos, as it speaks to our commitment to providing innovative, reliable and cost-effective solutions to our customers.”

Related Content

Titanium Golf Club Line Leverages AM to Boost Clubhead Performance

Japanese lifestyle golf brand Designer utilizes Farsoon 3D printing to optimize the design and production of its latest titanium golf club line.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreSpherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More