To hear David Abbott and Todd Rockstroh of GE Aviation talk about additive manufacturing—specifically, making aircraft engine parts through direct metal laser sintering or selective laser melting—is to hear these men tick through a litany of very serious challenges.

For example:

• The properties of metals created through these processes are far from proven. Are the properties equal to the performance demands that jet engine components require? Are the properties repeatable?

• The dimensional accuracy of additive metal processes is not inherently fine enough for GE’s tightest tolerances. Thus, the company has learned machine calibration methods for improving accuracy. The company is developing compensation models for tightening it even further.

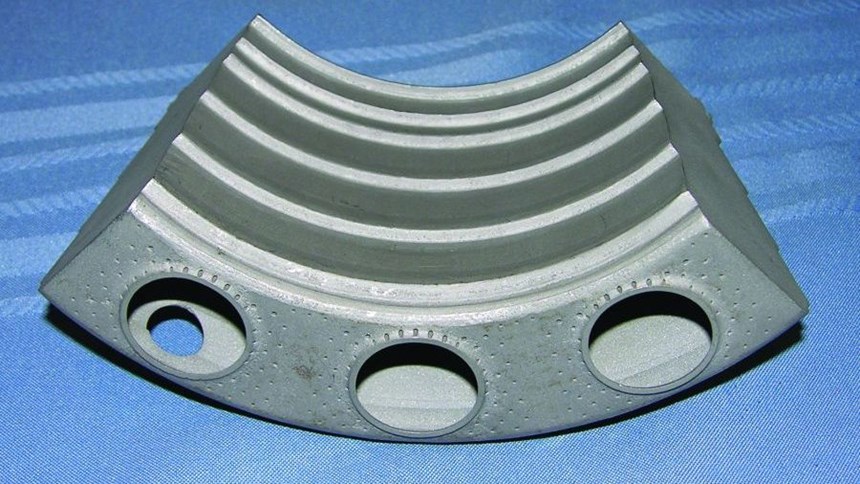

• An important benefit of additive manufacturing is its ability to make complex internal features, but the roughness of those features affects fluid flow and fatigue life. How can these intricate inner surfaces be finished?

• During additive production, parts move. Parts distort. Building a critical component entails finding just the right orientation for the part and engineering just the right support structure for it. Figuring all of this out can take many builds, each one of which is time-consuming. Is there a faster way to arrive at the optimal process?

Given all of these challenges and others, does additive part-making still make sense? Does it still hold potential for aircraft engine component production?

Absolutely, the two men say. Without a doubt, yes.

“This is the future of manufacturing,” Rockstroh says.

The struggle is leading somewhere. All of these challenges will eventually be overcome. The potential value of additive manufacturing is great enough to overcome the cost of facing even all of the challenges above.

1,000 Pounds

Rockstroh and Abbott are part of a GE Laser Applications team in Evendale, Ohio, charged with advancing additive metal manufacturing. The team has been engaged with this work for many years, but the attention given to additive manufacturing has increased in the last few years as the technology has improved to become increasingly viable for production.

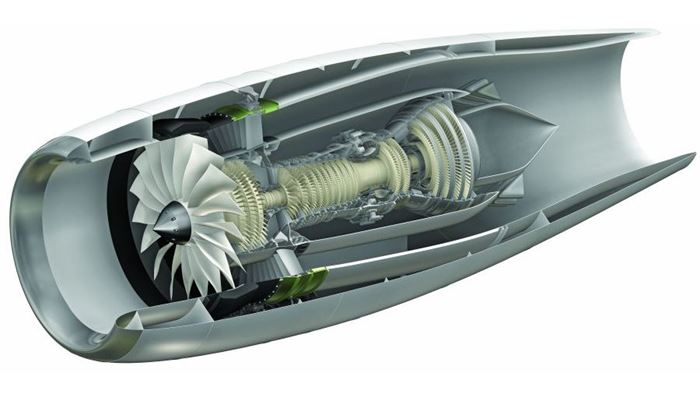

The reason the promise of additive manufacturing is so great is because aircraft engine components, like manufactured parts in general, are designed to fit the limitations of manufacturing methods. A hole is straight because a drilled hole can only be straight, for example, or a casting is thick in a certain spot because the metal flow of the casting process requires thickness in that area. Also, assemblies add extra stock just for the sake of brazing and welding steps necessary to join the components. Requirements such as these add weight to the engine, and that extra weight affects what the airplane can do.

But additive manufacturing will enable engineers to redesign components so that the parts deliver the same or better functionality with much less mass. It will allow “unmachinable” shapes, and it will allow assemblies to be replaced with single pieces. GE Aviation has begun an initiative to redesign component after component within one of its engines to take advantage of the weight savings it expects from additive production.

“On a 6,000-pound engine, we expect to save 1,000 pounds,” Rockstroh says. Such dramatic savings will permit similarly dramatic improvements in aircraft payload, fuel efficiency and performance.

For now, some of the weight savings will be hypothetical. They assume part designs that will not be practical to produce until additive machines become faster and more cost-efficient. The equipment is moving in that direction.

Meanwhile, cataloging those 1,000 pounds of savings will show GE where the easiest opportunities are, and where the simplest component redesigns can be found, so the manufacturer knows where to concentrate its next efforts as soon as the first additively manufactured component leaves the Laser Applications group to enter full production—a milestone that is about to be reached. Abbott and Rockstroh’s group is in the process now of transferring that first part to its first production supplier.

More Than Form

Which engine component will be first into additive production is a detail that GE wishes not to announce. But like many components inside a jet engine, this part faces performance demands including thermal cyclic loading across a dramatic temperature range.

Those performance demands highlight the difficulties that the advance of additive manufacturing faces—difficulties that aren’t necessarily apparent when watching how elegantly a 3D printing machine can produce an elaborate shape. Form, fit and function are the three areas of a part’s requirements. Abbott says form is the characteristic that additive processes accomplish fantastically well. The other two areas present difficulties.

“Fit we can get to, but it takes work,” he says. Refinement of the additive cycle and/or secondary processes such as machining are needed to achieve tight dimensional control.

Function, he says, is the area that is not assured. The metals used in the company’s established manufacturing processes meet stringent consistency requirements, and the components produced from them meet equally stringent performance requirements. Simply put, is an additive part as reliably resilient and durable as a component machined from a casting or a solid block?

In many cases, no. However, the work is continuing. The additive processes are improving, and the team’s successes at making better use of those processes continue to mount.

Getting the first additively manufactured part into full production will be the most important success of all, says Abbott, because the challenges on the way to completing this step have taught the GE team lessons that will apply to every other additive part going forward. Because of the discoveries that have now been made, probably no other component will be as difficult to shift into additive production as the first one was.

Full Production

That first part will begin production this year, as GE Aviation transfers its proven manufacturing process for the part to an initial supplier. A second supplier will come next year, Rockstroh says, and by 2015, enough suppliers should be making the part that additive production can account for all of the part’s demand. By the time that happens, other additive parts will also have been shifted into production—presuming the production capacity is there.

The supply chain is one more area of challenge that has to be addressed, he says. That first GE Aviation additive part, if run at full production today, would consume most of the direct metal laser sintering capacity currently available for production use in North America. Obviously, this is a problem.

That is why the company says one of two advances will have to happen in the next few years. Either the number of additive manufacturing machines available for production in North America will have to increase, or machine technology will have to improve to the point that the machines coming into use are faster than machines today.

Neither expectation is unreasonable. In fact, given the rate at which the market and the technology are advancing, Rockstroh says the likelihood is that both of these developments will occur.