Aerospace

GE Announces Additive Manufacturing Breakthrough in Commercial Aviation

Additive manufacturing is fulfilling its promise in the aerospace industry more than any other, as evidenced by more than 300 additively produced parts that help compose the new GE9X engine. GE Aviation has brought industrialized next-generation aerospace through additive manufacturing.

Read MoreIncodema3D Reaches the Tipping Point for Production Additive Manufacturing

The New York manufacturer is launching into its first continuous flow production job for metal AM. Owner and CEO Sean Whittaker shares what it took to arrive here.

Read MoreSolvay, Stratasys Partner on AM Aerospace-Grade 3D Printing Polymer

The companies will develop an aerospace-grade polymer for use with Stratasys’ 3D printers.

Read MoreMission Critical: An AM Breakthrough in Commercial Aviation

The GE9X is the first commercial aircraft engine to reach production with significant additive content. The story of GE’s accomplishment and why it matters.

Read MoreMarkforged Launches Flame-Retardant Material for 3D printing

Markforged, manufacturer of metal and carbon fiber 3D printers, has released Onyx FR, a V-0 rated flame-retardant material designed for industries such as aerospace, automotive and defense.

Read MoreWhat Is the Role for Additive Manufacturing in Aircraft Structural Components?

Spirit AeroSystems recently began installing the Boeing 787’s first titanium structural component to be made through AM. The part is not critical but also not minor. I spoke with manufacturing leaders at Spirit about the meaning of the part and the way forward for additive in aircraft structures.

Read MoreLarge-Format Additive Manufacturing: Viable for Autoclave Tooling?

SABIC and the University of Dayton Research Institute explore the potential of using large-format additive manufacturing (LFAM) technology for creating autoclave tooling used in manufacturing aerospace composite parts.

Read MoreNASA Funds Auburn University for AM Aerospace Growth

The research and development covered under a contract between Auburn University’s Samuel Ginn College of Engineering and NASA’s Marshall Space Flight Center will focus on evolving light-weight, large-scale additive manufacturing techniques for regeneratively cooled thrust chamber assemblies.

Read MoreDMP Factory 500 Offers Workflow-Optimized Metal 3D Printing

Designed by GF Machining Solutions and 3D Systems, the DMP Factory 500 metal additive manufacturing (AM) printing solution is said to create seamless large parts with increased quality and lower total cost of ownership (TCO) for aerospace original equipment manufacturers (OEMs) and their suppliers.

Read MoreAdditive Technology Delivers Small Satellites to Space

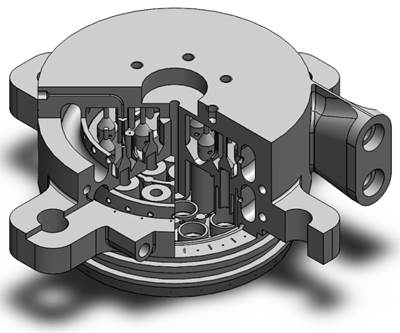

Researchers at the German Aerospace Center (DLR) have developed a reusable rocket engine specifically for the launch of small satellites. The complex injector heads are 3D printed which unlocks additional performance, reduces the parts count, speeds up production time, and reduces weight and costs.

Read More