Additive manufacturing (AM) has been part of aircraft production for years, but its role has largely been limited to noncritical parts such as ductwork and interior components, or engine components (like the famous GE Leap engine fuel nozzle) for which the stresses involved are thermal rather than mechanical. AM will have fully arrived for aircraft part production when it is a solution for making structural components, but how far off is that possibility? In one sense, it is still in the distance. In another sense, it is here today.

Spirit AeroSystems, which manufactures fuselages for Boeing commercial aircraft, has recently begun installing the first titanium structural component made through additive manufacturing for the Boeing 787. The part is a back-up fitting for an access door latch. A bracket, essentially. This part is not so critical that the plane couldn’t fly home if it failed, but the part is important enough that the plane should fly home if it fails. Being trusted with this much importance on a commercial aircraft is an advance for AM.

Other advances will wait. This part is an additive version of precisely the same part design previously produced through machining. Dramatic redesign of the part to achieve some of the special advantages of AM, such as weight savings or assembly consolidation through organic or intricate 3D-printed forms, is simply not practical given the aircraft industry’s preference to certify a part design and stick with that design throughout the production life of the plane. These bolder possibilities from AM, at least for structural parts, will have to wait for opportunities in the future, as new parts are designed for new aircraft. And the use of additive for structural parts far more critical than the door latch fitting might need to wait for quality assurance techniques specially suited to additive that do not yet exist.

But all of this is coming. Not only does Spirit expect additive manufacturing to play an ever-growing role in aircraft production, the company also recognizes that Tier 1 organizations like it might be in the very best position to deliver on this role. Because of the nature of AM, neither the aircraft OEM nor the sub-tier suppliers farther out in the supply chain are as well-suited to pursue and realize additive’s promise. The transition of the door latch fitting from machining to additive is therefore beneficial in multiple ways: Narrowly, it reduces the cost of this part by significantly reducing the amount of metal needed to make it, and broadly, it blazes a trail Spirit expects to follow repeatedly as it transitions other structural parts to additive and then begins to develop structural parts that are 3D printed from the outset.

On a recent visit to Spirit’s 11,000-employee manufacturing campus in Wichita, Kansas, where Boeing 737 and 787 fuselages are made today and where B29 bombers were produced during World War II, I talked with members of the team involved with additive manufacturing about the door latch fitting and what it means. With a fitting and with another, failed 3D-printed part on the table in front of us (more on that below), I spoke with Spirit employees Scott Bishop (R&D), Michael Cumming, Keith Kasych (Structures Certification, Analysis and Testing) and Paul Toivonen (Core Structures Engineering and Testing).

This last team member made the comment that hung over much of our discussion. “When we talk about additive for structures,” he says, “certification is the elephant in the room.”

The door latch fitting was a part able to win certification for the conversion to AM. Meanwhile, he and others at Spirit are working with the Federal Aviation Administration (FAA ) to directly confront this elephant.

Targeting Titanium

The AM version of the door latch fitting is 3D printed by Norsk Titanium using its proprietary Rapid Plasma Deposition (RPD) process. The name describes the process: A plasma arc allows for controlled deposition of titanium at rapid build rates. Spirit has worked with Norsk Titanium for years to explore and qualify RPD, with the result that this is Spirit’s go-to method for the time being for making production additive parts in titanium, the metal on which the company has been focused in its search for wins for AM.

Kasych explains why. “Titanium is expensive and manufacturing-constrained,” he says. Machining slender parts out blocks of titanium is expensive two ways—first in the amount of metal that must be purchased, second in the amount of machine time and cutting tool expense that goes into machining the metal away.

Plus, the use of titanium has expanded. Because of the needed stiffness, carbon-fiber composite parts (the 787 is notable for these) have to connect directly to titanium parts, not aluminum, meaning many components that might once have been from easy-to-machine aluminum are made from more challenging titanium instead. The result is perhaps counterintuitive: “Expanded use of composites will lead to greater opportunities for metal AM,” Kasych says.

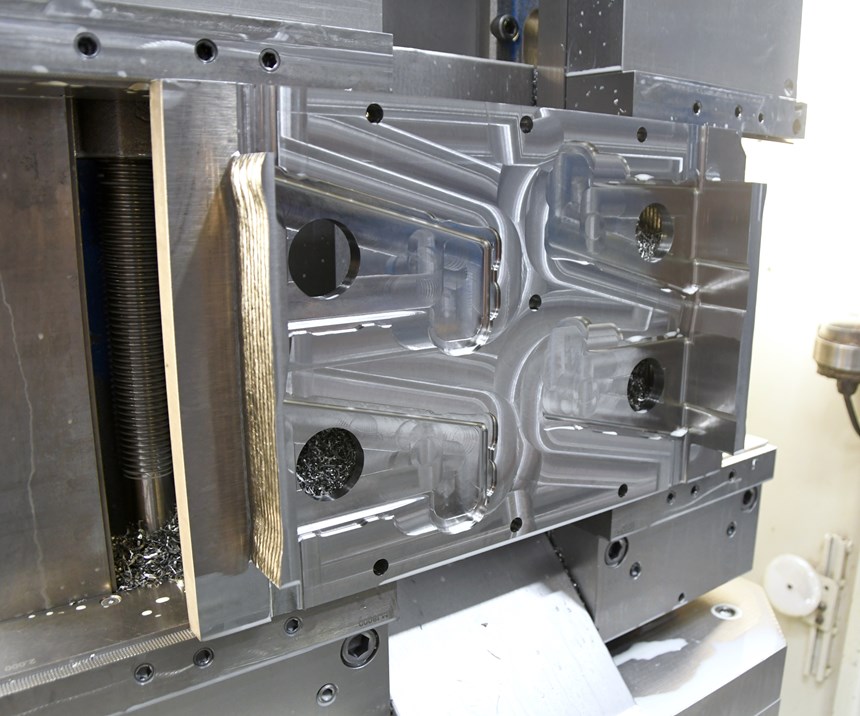

The aircraft-industry term for talking about the cost and waste of machining is the “buy-to-fly ratio”—that is, how much metal needs to be purchased as a multiple of how much metal remains on the finished part installed in the aircraft. An aircraft component machined out of a solid block could easily have a buy-to-fly ratio of 20-1, meaning 95 percent of the metal is machined away. Making the same part through RPD could drop the ratio below 3-1. The process is fast relative to powder-bed metal additive processes, but also more coarse and less precise than these processes, leaving a larger envelope of stock in need of machining away.

Yet buy-to-fly reduction is not everything, and not necessarily enough to make the case for additive. The design of the AM build for the door latch fitting nests four pieces together to maximize the efficiency of the build cycle and minimize machining setups, even though this nesting adds some metal. Because of the nesting, “near-net-shape” in the case of the door fitting is not as near as it might be.

Another part makes this point more strikingly, the failure I mentioned. This was a case of a prospective additive part for which AM did not deliver sufficient value to win adoption. The part’s 3D-printed form resembles parallel fins, with one fin curving at one edge to flow into the other. This complex cantilevered form proved so challenging to machine without chatter that the escalation in machining cost offset the material savings. Machining this part from a solid block proved easier, so that’s the way it will continue to be made.

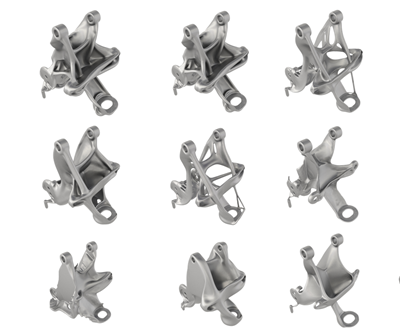

In the future, though, the determination won’t look like this. The choice won’t look like this. For new parts made additively from the outset, part geometry will be modified to make machining easier. Design for additive manufacturing (DFAM) is the opportunity still to come, Kasych says. The real wins from AM won’t involve just material reduction; they will include part weight minimization via topology optimization or generative design, reduction of assembly by consolidating systems into single 3D-printed forms, and faster time-to-market as a result of reducing the number of manufacturing steps. And Spirit will have an important role to play here, because in DFAM, design and manufacturing go hand-in-hand more than ever before.

Where DFAM Happens

Additive manufacturing is more than 3D printing, notes Toivonen. He cites the steps involved in AM for a titanium part. The build is the defining step, but the process also includes machining and heat treating, as well as some form of nondestructive inspection such as CT scan. The steps are few, simplifying manufacturing. Yet that very simplicity complicates certification, because with so much happening at once, the process is harder to predict or control.

“With additive, you’re making the part’s microstructure at the same time you’re making its geometry,” he says. Plus, “the metal, the additive machine and the heat treatment all affect microstructure”—and they all react to one another and to the part geometry in the way they affect the microstructure. With all the interrelatedness of variables, the development of the additive process for a given part and even the development of the design for that part almost inevitably have to be iterative.

This is very different from conventional manufacturing, where the performance of various process steps is better known because the constraints at each step are more limiting. With casting, forging or machining, a design engineer knowledgeable in any of these processes can create a part model with high confidence that the foundry, forge or shop will accurately produce it. Additive is not like this. The design engineer sending an early version of a part through 3D printing and its downstream steps is likely to discover an inefficiency of the process or shortfall in the outcome calling for a change to the process or a change to the design. Design for additive manufacturing therefore tends to involve design via additive manufacturing.

All this speaks to why Spirit aims to develop AM expertise. And all this relates to the role Spirit sees for itself in the advance of additive as a means of realizing more cost-effective and better-performing aircraft in the future. As a first-tier supplier, Spirit is already integrated closely enough with its customers, the largest of which is Boeing, that it participates in part design today. Tomorrow, as Boeing and other aircraft makers look to realize the weight, cost and time savings available from additive, Spirit’s design role will seemingly have to increase. Its customer, the aircraft OEM, without all the manufacturing capabilities under-roof that ultimately affect the design of the AM part, is not in a position to complete part designs on its own to the same extent that conventional manufacturing permits. And a supplier using additive farther downstream in the supply chain would be too far from design to let AM realize its opportunities. The sweet spot for the advance of production AM would seem to be Spirit’s spot, Tier 1.

Quality Question

But that leaves Spirit also beholden to join its customers in facing the elephant previously mentioned: certification. Realizing the full promise of additive manufacturing means finding the reach of that promise in terms of the extent of structural parts that might be candidates. Again, with additive, the material and part form are created at once, and the process factors influencing both are interrelated. A single-point quality inspection at the end of the AM process can’t capture every outcome that process has delivered, and a linear sequence of inspections throughout the process also won’t necessarily work, because the interactions between process steps aren’t necessarily flowing linearly.

Fortunately, there is precedent for finding different ways to certify parts, Toivonen says. The introduction of carbon-fiber composite parts also entailed the challenge of recognizing that the material form and material properties are being created simultaneously. The range of variation is not as great as what additive presents, but the challenge is similar enough to suggest a way forward.

Toivonen says the FAA is an engaged partner in this. Regulators have seen additive come to engine parts; they know it is also coming to structures. They know it holds the promise for better-performing and even safer planes. The key is to find the way to know, with the level of certainty appropriate to the part, all the significant properties and outcomes the additive process has produced. Today, it is not possible to know this well enough to certify parts critical to flight if they are made through AM.

But there is enough data to know this, at least in theory. Data on part formation captured during the additive build can be mined for its effects on downstream processes and on the final properties of the part. Artificial intelligence tools such as machine learning will probably be leveraged to find the relationships between input data and outcome effects. Quantum computing might be employed to analyze the data in real time, Toivonen says. There is significant opportunity for AM already in aircraft structural parts. And if there is a place for additive in parts far more critical than the door latch fitting, he says, “The certification involved will probably be predictive, and it is likely to involve technologies that haven’t fully arrived yet.”

Related Content

Beehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read More8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreRead Next

Engine Mount Set to Be First 3D-Printed Part on the Moon

Manufactured by RUAG Space, the 3D-printed engine mount is part of a spacecraft from SpaceIL.

Read MoreWhy GM’s Electric Future Is Also an Additive Future

Production capacity isn’t the only reason that additive has been slow to make inroads into the automotive industry. There is a larger barrier to entry—one that General Motors and Autodesk are working to overcome.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More