Incodema3D Reaches the Tipping Point for Production Additive Manufacturing

The New York manufacturer is launching into its first continuous flow production job for metal AM. Owner and CEO Sean Whittaker shares what it took to arrive here.

Inside an EOS M280 in Ithaca, New York, a build cycle is about to end. Soon, a build plate containing 55 identical Inconel 625 parts will emerge. These parts will join others, traveling on to stress relief, cut off and finishing. Within sight of the 3D printer, four lathes are already at work, busy turning each cylindrical piece to tap the threads on both ends. Five thousand of these parts will be 3D printed and shipped from this facility in the next month, and for each of many months to come. This is the new reality at Incodema3D. This is what production additive manufacturing looks like.

For Sean Whittaker, president and CEO of Incodema3D and its three sister companies, this job is a tipping point. For more than seven years now, the Incodema Group has been moving toward production AM, first incorporating metal 3D printing as part of its core sheet metal business in 2012 and later breaking Incodema3D off into its own AM-based enterprise in 2014. Now, after years of process development and piecemeal production, this business is launching into its first continuous flow production job to be manufactured with metal AM.

Welcome! You’ve unlocked premium content.

“Right now, we’re at a 60-40 percent mix of development to production work,” Whittaker says. “Our goal over the next two years is to get to 20 percent development to 80 percent production.”

This new job is the realization of part of that goal, an example of a successful transition from product development into additive manufacturing. But growing the production portion of the business will entail more development. “The supply chain doesn’t exist for these parts,” Whittaker says of these first continuous flow production pieces. “We had to develop it.”

That development has taken time and resources, but it is now about to pay off. Incodema3D’s journey illustrates the promise of production AM as well as what it takes to bring an enterprise to this tipping point.

Building AM Infrastructure

Incodema3D has steadily acquired metal 3D printing equipment over the last seven years, starting with EOS M280 direct metal laser sintering (DMLS) machines. The company now owns six of these models, many of which have been qualified by aerospace OEMs. The company has also added two M290s and four M400s, EOS’s larger format platform targeted for production. The printer fleet is rounded out by two 3D Systems ProX DMP 320s and a Renishaw AM 400. Machines are dedicated to specific materials, and today most are designated to either production or development, with development taking up the lion’s share. While Incodema3D uses a mix of equipment and is continuing to explore new options on the market, the EOS machines have become its workhorses as a result of easily accessible parts (thanks to EOS’s recently established Austin, Texas, technical center), service and support, Whittaker says.

But production AM is not just about the 3D printers, as Whittaker is quick to point out. “If you don’t have the infrastructure, you can’t play in the sandbox,” he says. And Incodema3D has had supporting infrastructure since the beginning, when the company was established within the Incodema sheet metal business. When it broke off into its own facility, some of the machining centers and other equipment from the sheet metal business came along with the printers.

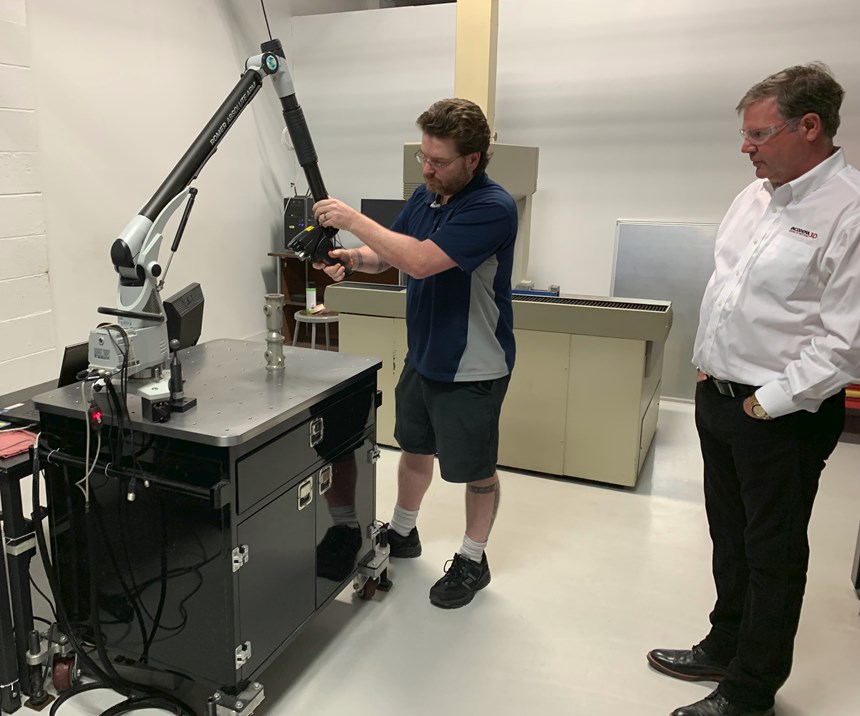

Today, Incodema3D handles just about every part of its AM supply chain in-house, from product development to 3D printing to post-production. In addition to its fleet of metal 3D printers, the company is equipped with a Romer laser scanner and other inspection equipment; multiple wire EDMs and band saws for part cut-off; and ten machining centers and four lathes for finishing. One of the few things the company doesn’t do in house is heat treat, which is performed by certified outside agencies. Parts on their build plates are laser scanned before they leave for heat treat, and again when they return to ensure quality.

Beyond equipment and process needs, there are also the consumables to consider. The Ithaca facility is set up in a linear flow mirroring the way that raw material moves through the process. Metal powder is delivered at one end of the building, where a line of material-designated sieving stations sits ready to feed it into cannisters compatible with the shop’s printers. This allows for off-line material management rather than sieving at the machine, and also limits exposure for operators. Future plans for the building include enclosing materials storage and sieving into its own room for added quality control.

While powdered material for 3D printing needs proper handling and storage, Whittaker points out that it offers some major advantages over machining stock. “Traditionally you would need a fleet of buyers pricing out different sizes and shapes of stock,” he says. “Here the raw material comes in a bucket.” Incodema3D’s 10-kg cannisters are bought on consignment, so the supplier owns the product until the container is opened. Whittaker’s hope is that some day powder will come in much larger containers. “Aerospace wants traceability,” he says. “Larger lots of material would mean less paperwork!”

Build plates are another point to consider; the volume of 3D printing happening at Incodema3D and the fact that plates full of parts leave for a week at a time for the heat-treat process means that the company must have a sufficient inventory of build plates at all times that are constantly being tracked, refurbished and fed back into the process.

Keeping track of all these moving parts requires—and generates—a significant amount of data. To manage it, the Incodema3D and its sister companies have an in-house ERP system built from the ground up that is used across all four businesses, now including production AM. The software offers a robust quoting system that integrates with the company’s other platforms to account for the whole manufacturing process, including operations that might be performed by other companies within the Group. Aerospace parts for instance often undergo photochemical machining at sister company NewCut, which uses chemistry and agitation to remove loose powder, unsolidified microbeads and even supports from metal 3D-printed parts. The Group-wide ERP system provides travelers that follow each part from 3D printing through scanning and heat treat to final machining, accumulating data that is part of the final output delivered to customers.

Development and Focus

“It takes a long time to nurture customers, establish credibility and qualify machines, and then parts,” Whittaker says. The time from development to production readiness for a 3D-printed aerospace part is 18 to 24 months on average. The market and therefore AM’s credibility are catching up, but the qualification process still takes time. 3D-printed parts must meet thresholds for tensile strength, elongation, fatigue and other mechanical properties that would be required of machined parts. But they also require validation by NADCAP-certified labs to confirm metallurgy, a process that nearly doubles the cost of each part. There’s also the issue of certifying each AM machine that will build a given part. “A machine shop would never do this,” Whittaker points out, but AM machines are not analogous to machine tools. “In the casting industry, you certify by the foundry. Think of each AM machine as a foundry.”

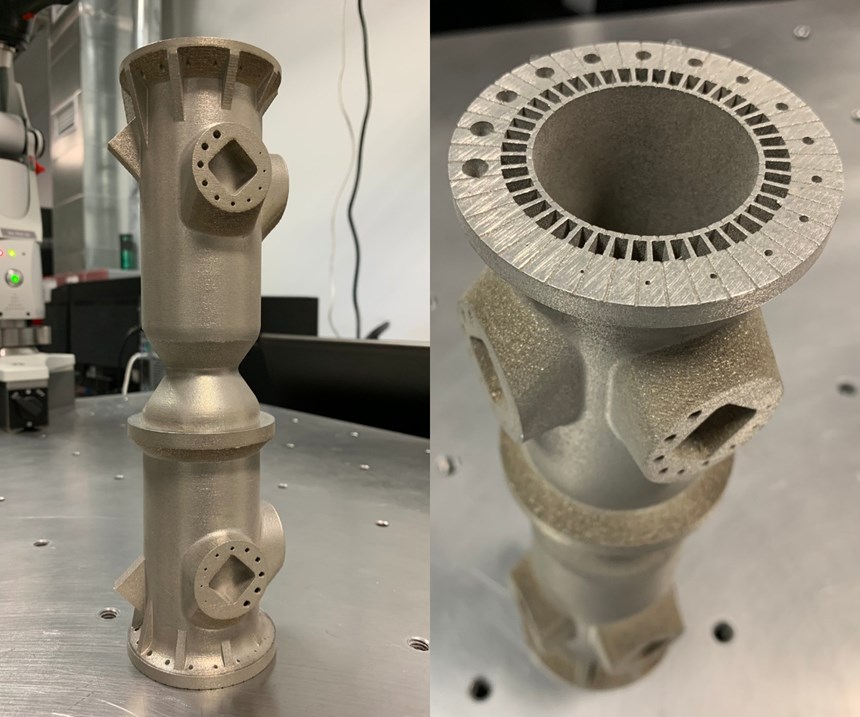

Incodema3D’s history in the aerospace industry has led it to focus on a certain type of part: typically those with internal channels and components where thermal properties are important. An example is the rocket launch nozzle seen above. This roughly cylindrical part features internal channels with port connectors, consolidating a once-welded assembly into just one piece. The nozzles are printed nine to a plate, and have been designed so that no overhang is more than 45 degrees, negating the need for support structures.

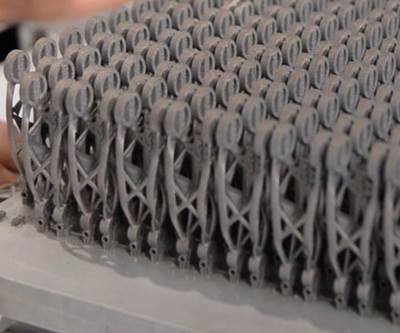

While aerospace remains the core of Incodema3D’s business, it also finds opportunities in other industries that need complex metal parts. One such crossover application is a line of luxury faucets Incodema3D produces for American Standard. These faucets were designed as showpieces to demonstrate the capabilities of metal 3D printing; the latticed model pictured above features 1-mm internal channels for the water flow, in a design that could not be manufactured otherwise. The faucets were positively received in the kitchen and bath industry, however, and ultimately became a sellable product. Incodema3D worked to dial in the print parameters, and developed a decoupled build plate solution providing some spring-loaded “give” for part interference with the wiper blade that allowed batch sizes to go from three to 10 per plate. Today the company manufactures about 100 of these faucets per year in three styles.

Waiting Out the Market

Production has always been the goal for Incodema3D, but until recently the work has been piecemeal, made in small batches as needed. “Production” until this point might have meant a hundred parts per year, or a few dozen every few months. Now, production will mean something different.

With this first continuous flow job, Incodema3D will be manufacturing about 5,000 parts per month. Each of these cylindrical pieces must be 3D printed, heat treated, cut from the build plate, and internally tapped on both ends. (Due to the proprietary nature of these parts, they could not be photographed for this story.) Completing this work on a continuous basis will take four or five of the M280 machines and four lathes running two shifts, not to mention the numerous build plates and material batches required, laser scanning cycles, EDM time, and more.

For Incodema3D, this is only the beginning. While this first production job is for the defense industry, the company expects that aerospace will soon follow.

“You have to do development to get to production,” Whittaker says. “But once you nail the process, 3D printing builds are very predictable in time. Machining cycles can likewise be optimized for cost. The challenge becomes matching throughput.”

Aerospace is especially well-suited to this philosophy, as aircraft programs typically extend far into the future. Once a 3D-printed part has been validated on a specific machine, the manufacturer who owns it can likewise own this work until the program is complete. This is how Incodema3D will reduce its development work and increase production over time; this is how the ratio shifts, from 60-40 to 20-80.

Now at the crest of this tipping point, Incodema3D is still moving toward the same horizon it saw five years ago, upon moving into its current facility. While today the shop floor is open and seems sparsely utilized in some areas, this is intentional. The printer fleet consists of 15 metal AM systems, but the facility is set up to support 100. As more development work becomes production work, so too will the number of dedicated “production” 3D printers grow.

Related Content

Why AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreAdditive Manufacturing's Evolving Role at Fathom Now Emphasizing Bridge Production

Bridge production is currently the biggest opportunity for additive manufacturing, says Fathom Manufacturing co-founder Rich Stump. How this service provider leverages AM while finding balance with other production capabilities.

Read MoreThe Arrival of the AM Factory: How Proprietary Processes Deliver Production 3D Printing

Various recent articles report on companies using internally developed technology to equip factories and deliver on the promise of AM for production.

Read MoreAdditive Wins on Cost, Plus Process Monitoring and More from RAPID + TCT 2023: AM Radio #38

Additive manufacturing is finding success as a cost-effective manufacturing method. New options for process monitoring are now available. DED is getting more precise. 3D printed chairs! What we learned and observed at RAPID + TCT 2023.

Read MoreRead Next

Testing the Waters with DMLS Faucets

A plumbing products manufacturer is expanding its luxury line with a series of faucets that could only be produced with AM.

Read MoreIn Additive’s Evolution, Aerospace Proves the Fittest

As additive manufacturing shifts from prototypes to production, one industrial sector is ahead of the curve.

Read MoreAdditive Manufacturing Is Succeeding in Production! Here Are Examples

We are no longer predicting that additive manufacturing will be used in production — because it already is. Find real stories of 3D printing for full production at AM's leading edge in this collection.

Read More

.jpg;width=70;height=70;mode=crop)