Markforged Launches Flame-Retardant Material for 3D printing

Markforged, manufacturer of metal and carbon fiber 3D printers, has released Onyx FR, a V-0 rated flame-retardant material designed for industries such as aerospace, automotive and defense.

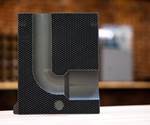

Markforged, manufacturer of metal and carbon fiber 3D printers, has released Onyx FR, a V-0 rated flame-retardant material designed for industries such as aerospace, automotive and defense. Traditional 3D printed plastics will burn if they catch fire, but this new material is said to be self-extinguishing, capable of stopping itself from burning. Onyx FR features high strength, improved print quality and high-quality surface finish—all while resisting fire.

Onyx FR is compatible with Markforged’s Industrial Series printers. Onyx FR joins Markforged’s portfolio of industrial metal and composite materials. The company recently raised funding to expand its product line to include investments into composites fabrication.

“Onyx FR opens up more applications for 3D printing across automotive, aerospace and defense industries because it meets higher fire safety standards,” says Jon Reilly, vice president of product at Markforged. “When these parts are reinforced with strands of continuous carbon fiber, they are as strong as aircraft-grade aluminum at half the weight.”

Related Content

-

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

-

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.