Articles

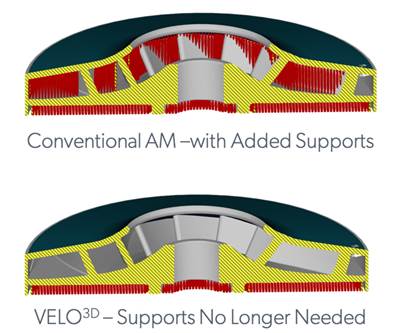

Velo3D: Avoiding Support Structures Means Metal AM Can Be a Solution for Direct Part Replacement

Because of the extent of the redesign they might call for, support structures can be an impediment to AM adoption. Reducing the need for support structures increases the viability of 3D printing for current parts.

Read MoreAre Emissions from 3D Printing Hazardous to Your Health?

And if so, what can you do about it? NIOSH researchers share the organization’s approach to eliminate, avoid and reduce operator contact with volatile organic compounds (VOCs) and ultrafine particles from fused filament fabrication (FFF) 3D printers.

Read MoreVideo: Additive Manufacturing Expands Design Possibilities for Automotive Lighting

Automotive lighting maker Varroc Lighting Systems describes the impact 3D printing instead of injection molding will have on car features such as headlights.

WatchWhat Is Material Jetting 3D Printing?

Recent advances in materials processing capabilities have renewed interest in material jetting, the additive process that allows 3D objects to be built by placing different combinations of material drop-by-drop.

Read MoreUltem, PEEK or PEKK? Choosing Between High-Temperature Plastics

How do you choose between these high-performance materials? A conversation with Arkema and Plural AM sheds light on 3D printing with these polymers.

Read MoreOptimize Additive Manufacturing Designs for Cost AND Function

While manufacturers are now replacing parts and assemblies with 3D printed components to reduce cost, material and weight, there is still more opportunity to improve the functionality of the design. Robust design and modeling software are critical to realizing this potential.

Read MoreAs 3D Printing for Production Becomes Practical, the Attention in Materials Shifts to Practical Concerns

Recent posts relate to ensuring sufficient materials supply for production, certifying processes for AM materials, and even whether the properties of polymer AM include the ability to hold a screw.

Read MoreThe Race to Faster, Cheaper and Better AM for Aviation

An aviation industry partner called NIAR may be the largest institute you've never heard of. But through a new materials and process database for additive, it’s promising to help aviation manufacturers produce AM parts faster, cheaper and more reliably than ever before.

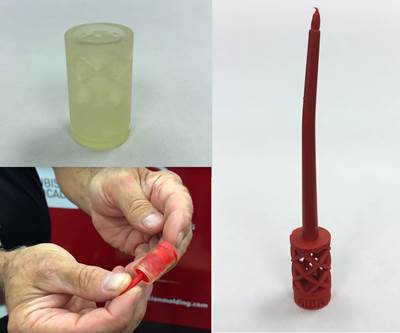

Read MoreInjection Molding with the Geometric Complexity of 3D Printing

The Freeform Injection Molding (FIM) process from Addifab allows for injection molding resins to be processed into shapes not otherwise possible.

Read MoreAM at Jabil: From 3D Printing Materials to Distributed Manufacturing

One of the largest manufacturers in the world has made a significant investment in 3D printing — both as a user and an advancer of this technology. Our original reporting dives into the what and why of additive manufacturing at Jabil.

Watch10 Questions About Additive Manufacturing for Production with Jabil’s John Dulchinos

“We’re in this for the long haul,” he says. Here are the challenges facing 3D printing for production, and here are the ways those challenges will be overcome.

Read More8 Times 3D Printing Built a Better Bracket

Brackets may not be the most exciting application for 3D printing, but they are one of the most important. Here are 8 instances where a 3D printed bracket offered advantages over a conventionally produced one.

Read More