What Is Material Jetting 3D Printing?

Recent advances in materials processing capabilities have renewed interest in material jetting, the additive process that allows 3D objects to be built by placing different combinations of material drop-by-drop.

Of the seven basic additive manufacturing (AM) processes available, material jetting is the AM technology that is closest to what we use for printing text and images on paper. This is because the printheads that are used for material jetting are very similar to those used for inkjet printing, except instead of dispensing ink, they are depositing droplets of material that create a 3D object layer-by-layer.

The History of Material Jetting

The origins of material jetting technology date back to the mid-1990’s when Solidscape (initially called Sanders Prototype Inc.) commercialized “Drop-on-Demand” technology for 3D printing with wax. The company still specializes in material jetting systems for making very precise wax patterns for jewelry and investment casting, having being acquired in 2011 by Stratasys and then sold off in 2018 to Prodways.

3D Systems introduced its ThermoJet platform for material jetting about two years after Solidscape did, and they have continued to advance the technology into what it calls MultiJet Printing (MJP). Meanwhile, Israeli company Objet was the first to introduce material jetting for photopolymers in the late 1990s. They continue to develop and sell their PolyJet material jetting systems, having merged with Stratasys in 2012.

Material Jetting Printers: Click here to view suppliers

Recent additions to the material jetting space include companies like Quantica, Mimaki and Inkbit. Here, the Inkbit Vista features a build surface that passes beneath the print modules, then curing, scanning and cooling stations before repeating the process for the next layer. The process is sometimes called inkjet 3D printing.

What Are the Pros and Cons of Material Jetting?

Material jetting offers some distinct advantages over other AM technologies, but it also has its drawbacks. First, material jetting is fast. Material is jetted out a line at a time versus extruded from a nozzle or cured/fused by a laser. The material that is being jetted is photosensitive and is cured via ultraviolet (UV) light almost immediately after it is deposited. Because the layers are so thin (usually 16-32 micron), the material is fully cured when the part is done building; so, no additional curing or thermal postprocessing is needed as compared to parts made with many vat photopolymerization processes. Unfortunately, material jetting systems are still rather expensive given the complexity and proprietary nature of the printhead technology. Material jetting also requires supports for overhanging structures; however, supports can be easily dissolved away, leaving little trace of their existence.

Because of the small layer thickness, the dimensional accuracy of material jetting is very good, even when printing large parts, and parts made with material jetting have a great surface finish. Mechanical properties of material jetted parts are homogenous; however, the parts are relatively weak as they tend to be very brittle. This limits its use for functional components and end-use parts, but material jetting is great for prototypes, visual aids and tooling.

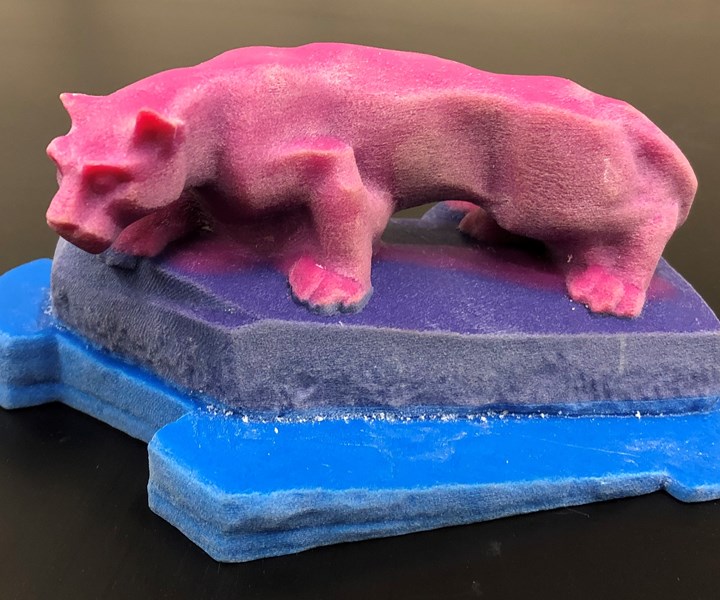

This lion statue was made with material jetting using two different materials (pink and blue), which are blended together to create a third material (purple). Photo credit: Nick Meisel, Penn State.

In fact, this is one of the areas were material jetting excels because today’s systems offer multiple printheads on a single machine. This allows users to jet multiple materials at once, mixing them in different compositions during the build (as shown in the photo above). As a result, material jetting can be used to combine hard and soft or opaque and transparent materials within a single part, giving rise to a “digital material” that can be controlled at the voxel level. For those of you familiar with Minecraft, this is a good analogy — instead of building virtual structures block-by-block, material jetting allows you to build 3D objects by placing different combinations of material drop-by-drop.

Applications for Material Jetting

As you might guess, material jetting also allows you to print 3D objects in color, just like we can print 2D images (and text) in color. Full-color parts are another reason that material jetting is great for prototyping, and it is finding a real niche making medical models and visual aids for training doctors and surgeons. MRI and CT scan data for a patient can be easily converted into a 3D point cloud and printed in color — with different textures and material properties — to help doctors plan complex surgeries and medical procedures. This not only reduces time in the operating room but also helps saves patients’ lives in many complex and challenging cases.

This heart model made on an Objet Connex 3D printer from Stratasys illustrates material jetting’s ability to combine different materials. The white portions are a rigid polymer, intertwined with a softer, rubber-like material. Models like this can help surgeons visualize and even practice for procedures before treating patients.

Materials for Material Jetting

Finally, like many AM processes, material jetting is seeing renewed interest thanks to recent advances in its material processing capabilities. For instance, Xjet recently introduced NanoParticle Jetting technology, enabling a new way to 3D print ceramic materials. Meanwhile, researchers at Nottingham University are jetting metallic inks alongside insulating polymeric materials to 3D print functional electronic circuits. Given these advances, it is only a matter of time before we are making 3D metal parts using similar technology to the 2D printers on our desks.

Related Content

6 Trends in Additive Manufacturing Technology at IMTS 2024

3D printers are getting bigger, faster and smarter. But don’t overlook the other equipment that the AM workflow requires, nor the value of finding the right supplier.

Read More3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreRead Next

AM 101: NanoParticle Jetting (NPJ)

The proprietary process from XJet builds ceramic and metal parts using nanoparticle suspensions. Learn how NPJ works in this introductory article, part of our AM 101 series.

Read MoreWhat Is Vat Photopolymerization?

Vat photopolymerization was the first AM process to be successfully commercialized. Three decades later, this technology has shown how AM is capable of scaling to volume production and making custom products on demand.

Read MoreExpanding Materials, Applications for Inkjet 3D Printing

Traditionally, the materials available for inkjet 3D printing have prevented the process from being used in production of end-use parts. But machine vision systems and AI are broadening the materials and applications for inkjet 3D printing.

Read More