As 3D Printing for Production Becomes Practical, the Attention in Materials Shifts to Practical Concerns

Recent posts relate to ensuring sufficient materials supply for production, certifying processes for AM materials, and even whether the properties of polymer AM include the ability to hold a screw.

Varroc’s Dylan Schickel shows me an automotive lighting assembly and the role 3D printed components will play. See below for links to videos drawn from our conversation.

Dylan Schickel, innovation leader with automotive lighting producer Varroc Lighting Systems, sees bright potential for additive manufacturing (AM) in producing car headlights and taillights. The freedom to make some components of car lights with 3D printing rather than injection molding will let auto designers offer a broader array of lighting options within a single car model. This freedom will be valuable, he says, because “a car’s lights are its bling.” Varroc-made car lighting with 3D printed parts inside will be on the road next year.

Schickel says the advance of AM platforms is only part of what gave Varroc confidence that AM could play a role in production. Just as significant is the commitment materials suppliers have made. Indeed, he thinks a key moment came two years ago when BASF announced the launch of a subsidiary focused on AM. The commitment of such a large materials company made clear to him and others that there ultimately would be enough capacity in materials development and supply to warrant trusting AM for production at scale. And that point illustrates the place to which we’ve now come with materials for AM: the focus on practical concerns.

Previously, the focus has been more on the possibilities: the new material options and chances for material blending additive will bring. Those possibilities are being realized. But the weight of concern in AM today has shifted toward more basic questions, such as: Will the materials supply meet the needs of full production? Can AM materials be applied using controlled and repeatable processes? Various recent articles we’ve posted on materials focus on these basic concerns.

Jabil is perhaps the leading company facing these concerns. This major manufacturer aims to produce just as reliably and effectively in 3D printing as it does in machining and injection molding. It is scaling up 3D printing at various sites around the globe. But a potential vulnerability relates to materials: An interruption in materials supply or the lack of just the right 3D printing polymer for an application could prevent the investment in AM from realizing its promise. Therefore, Jabil established its own development and manufacturing center for materials used in AM — a commitment AM was seen to require that conventional processes do not. Stephanie Hendrixson and I were the first media to see this facility, and her article is one of a series of pieces we’ve posted on production AM at this company.

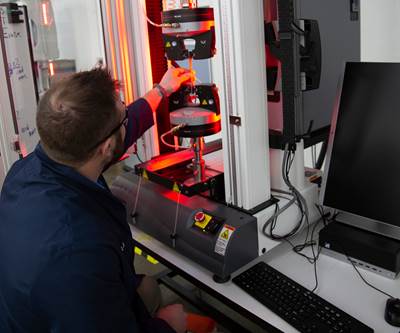

Then there is the question of developing, proving and deploying repeatable processes for AM materials. Helping to lead this effort for polymers in aerospace is the National Institute for Aviation Research (NIAR), subject of this report by Brent Donaldson.

New material options keep coming, of course. 3D printing with silicon carbide might become a reality and an innovation in 3D printing and moldmaking can deliver intricate AM geometries in any injection-moldable material. But the practical basics are increasingly the focus, including the most practical matter of all: keeping cost down by choosing the material that is most appropriate.

As for Dylan Schickel of Varroc, he has been exploring a production-related question that is basic indeed: Can 3D printed polymer parts hold screws? Watch our conversation in which he discusses his findings.

Related Content

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read MoreA Framework for Qualifying Additively Manufactured Parts

A framework developed by The Barnes Global Advisors illustrates considerations and steps for qualifying additively manufactured parts, using an example familiar to those in AM: the 3D printed bottle opener.

Read MoreNIOSH Publishes 3D Printing Safety Guide for Nonindustrial Settings

NIOSH has published a 3D printing safety guide for small businesses and other additive manufacturing users such as makerspace users, schools, libraries and small businesses.

Read MoreRead Next

The Race to Faster, Cheaper and Better AM for Aviation

An aviation industry partner called NIAR may be the largest institute you've never heard of. But through a new materials and process database for additive, it’s promising to help aviation manufacturers produce AM parts faster, cheaper and more reliably than ever before.

Read MoreVideo: Can 3D Printed Parts Hold Self-Tapping Screws?

Automotive light maker Varroc Lighting Systems will soon begin using additive manufacturing for plastic production parts fastened into assemblies. Here are the results of its tests with self-tapping screws.

Read MoreJabil’s Additive Materials Innovation Center: First Look

Additive Manufacturing Media was the first press to tour the Chaska, Minnesota, facility originally intended to be a clandestine additive manufacturing (AM) materials lab. What this capacity means for Jabil and 3D printing users.

Read More