AM at Jabil: From 3D Printing Materials to Distributed Manufacturing

One of the largest manufacturers in the world has made a significant investment in 3D printing — both as a user and an advancer of this technology. Our original reporting dives into the what and why of additive manufacturing at Jabil.

Why is Jabil interested in additive manufacturing (AM)? The global manufacturing solutions provider serving OEMs in various industries already does injection molding on thousands of presses and metalworking on thousands of machine tools. And therein lies the answer to the question: Jabil leaders say they expect AM not just to become a fully accepted production process, but also to transform production. Therefore, the company is investing to advance AM to this point today. By expanding its 3D printing capacity and certifying 3D printing within established quality standards, the company aims to be able to produce with additive manufacturing just as routinely and effectively as does with conventional processes.

To understand production AM at Jabil, we visited various sites within the company and spoke with Jabil team members involved with additive. Watch our video above for an overview, and find links to our original reporting below, starting with our interview with Vice President of 3D Printing and Digital Manufacturing John Dulchinos.

Jabil’s Additive Manufacturing Vision

There is a chicken-and-egg problem inhibiting AM from realizing its promise for production, Dulchinos says. To realize the full benefit of AM, parts must be designed for this process. However, OEMs are reluctant to commit the part design to AM without assurance of reliable and sufficient capacity in the supply chain. Jabil hopes to break this stalemate by qualifying and scaling up its own AM capacity to become this dependable AM production source.

The likely result will be a different mode of production, he says. Parts will be produced not in batches but in families, and they will be produced as needed for assembly without shipping or storage.

READ MORE

Solving the 3D Printing Materials Challenge

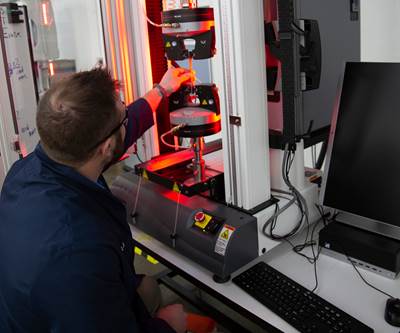

Additive Manufacturing Media was the first press to tour Jabil’s Additive Materials Innovation Center in Chaska, Minnesota. This 46,000-square-foot facility includes equipment for developing, testing and manufacturing materials for polymer 3D printing.

The purpose of this Center is partly to ensure that the right mix and volume of polymer 3D printing materials will be available as Jabil moves into AM production at scale. But another part of its purpose has to do with confidence. The facility focuses not just on creating new 3D printing materials, but on proving them out so that they print reliably on known machines with specified parameters. The long-term promise of that confidence is distributed manufacturing on a global scale, and the ability to manufacture where and when needed, in just the quantities required.

READ MORE

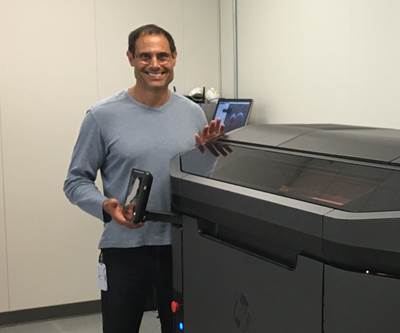

Production 3D Printing in Practice

With additive manufacturing, making parts and assembling parts no longer need to be separate. Jabil’s assembly facility in Auburn Hills, Michigan, has traditionally received all its components from machine shops and molders located elsewhere. That will change. 3D printing capacity at this site will allow parts to be printed just-in-time for production without entering into inventory.

AM technology is ready for this mode of production now. To apply AM and to realize this promise, Jabil is characterizing production 3D printing resources within the ISO quality system that defines the rest of the work of this plant.

READ MORE

Related Content

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreRead Next

Jabil’s Additive Materials Innovation Center: First Look

Additive Manufacturing Media was the first press to tour the Chaska, Minnesota, facility originally intended to be a clandestine additive manufacturing (AM) materials lab. What this capacity means for Jabil and 3D printing users.

Read MoreHow to Implement Additive Manufacturing Across a Global Company: 5 Lessons

With more than 100 facilities and about 200,000 employees worldwide, Flex has a steep challenge in bringing 3D printing into its operations. Five things the company is learning.

Read More10 Questions About Additive Manufacturing for Production with Jabil’s John Dulchinos

“We’re in this for the long haul,” he says. Here are the challenges facing 3D printing for production, and here are the ways those challenges will be overcome.

Read More

.jpg;width=70;height=70;mode=crop)