Velo3D: Avoiding Support Structures Means Metal AM Can Be a Solution for Direct Part Replacement

Because of the extent of the redesign they might call for, support structures can be an impediment to AM adoption. Reducing the need for support structures increases the viability of 3D printing for current parts.

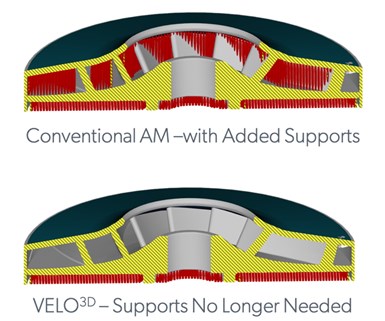

This graphic from Velo3D illustrates the challenge. An impeller is an example of a part design that might not be producible additively without major modifications to the design to facilitate support structure removal. Velo3D’s idea is that reduced need for supports will make more parts directly transferable to AM.

Metal additive manufacturing (AM) technology today too often requires the user to both design a new part and master a new process in order to implement AM effectively. That is too much, says Benny Buller, CEO of Velo3D. The need to accomplish all of this simultaneously represents a high hurdle that stands in the way of AM adoption. Instead, he says, “We want to offer additive manufacturing for direct part replacement.” Or direct assembly replacement in cases where a single 3D printed part replaces several components previously fastened together. In either case, he says, no redesign of the form of the component should be needed to make it producible via AM, because AM becomes much easier to use when this requirement is taken away. I recently spoke with him about this.

Support structures are the major factor. When a part is designed or redesigned for AM, the designer either omits overhangs that might droop during the additive build or, when this is impossible, adds in support structures to buttress those features. Adding supports might also entail redesigning the part to offer access to those features so they can be removed later via machining or manual postprocessing. A big part of what we think of as design for additive manufacturing (DFAM) is really design of and for support structures, and the impossibility of removing supports from many parts (because of inaccessible features) is why many existing part designs are not transferable to AM.

The Velo3D system is not just its machine, seen here. Control and software tools such as simulation, closed-loop meltpool control and feature-specific processing enable unsupported building of overhanging features and anticipation of part distortion or build failure.

Velo3D's “SupportFree” system is about making these designs transferable, he says. The system is the sum of various capabilities of the company’s metal AM system that together allow unsupported overhanging features to print effectively despite their overhang. Process simulation, closed-loop meltpool control, a non-contact recoater and feature-specific processing — meaning different parameters for different regions of the build — all figure in to allow reliable builds of non-DFAM parts with few or no support structures.

Another need for making metal AM more accessible is the reduction of the trial-and-error learning curve for realizing an effective and repeatable process. Much of this learning curve is aimed at finding a combination of process parameters than minimizes the incidence of part distortion or build failure. Velo3D’s system aims to control against these errors. “We learned the only way to control is to have metrology everywhere,” Buller says. The company’s years-long development process before its launch consisted in large part of failure modes and effects analysis (FMEA) aimed at identifying and characterizing parameters and variables that could suggest or lead to the build trending out of its window of control. The sensing and systems engineered around these parameters and variables results in an AM machine that “at every layer asks, ‘Am I still in control?’” he says.

Hidden inside this power generation component are labyrinthine gas-flow passages that seemingly would have ruled out additive manufacturing. The support structures for building these passages would have been impossible to remove after the build was done. 3D printing free of support structures made this part possible.

A recent success illustrates how this might play out in practical terms. KW Micro Power, a company working to develop a compact power generation system, had been stymied in trying to manufacture one of the key components of its design: a titanium disc roughly 10 inches in diameter containing a labyrinth of passages for gas flow. The form of the passages seemingly called for support structures, but support removal would have been impossible because of the passages’ inaccessibility. The combination of the build control and the SupportFree system enabled KW not only to additively build its design without supports, but also to print it accurately on the first try.

Related Content

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreThis Year I Have Seen a Lot of AM for the Military — What Is Going On?

Audience members have similar questions. What is the Department of Defense’s interest in making hardware via 3D printing over conventional methods? Here are three manufacturing concerns that are particular to the military.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreRead Next

Video: Support Structures Are Misnamed! How to Understand Anchors in Additive Manufacturing

Supports or anchors can account for a significant share of both the engineering investment and material use in metal additive manufacturing. Michael Hansen of SLM Solutions discusses the role and importance of support structures.

Read MoreCan Chemistry Set AM Free of the Cost and Constraints of Support Structures?

Support structure removal is costly and can prevent supports from being used in some areas of the part. This researcher may have found the answer that will make support structures easy.

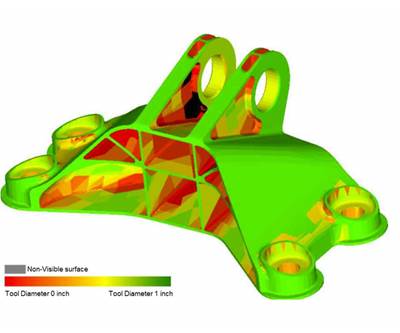

Read MoreCan My Machine Tool Access My Support Structures?

Analyzing the machinability of support structures opens a new way of thinking about optimal build orientation.

Read More