8 Times 3D Printing Built a Better Bracket

Brackets may not be the most exciting application for 3D printing, but they are one of the most important. Here are 8 instances where a 3D printed bracket offered advantages over a conventionally produced one.

When Editor in Chief Peter Zelinski summarized additive manufacturing’s (AM’s) opportunity in 2013, the one word he used was “brackets.” Drawing on a conversation with Dick Conrow, then-president of C&A Tool, this blog post made the point that some of the best use cases for AM would come from mundane parts, and what could be more so than brackets?

The past six years have proven just how right that prediction was and still is. While this publication has covered plenty of the splashy, attractive parts in the interim that Conrow cautioned against as potential distractions, we keep finding our way back to brackets, the functional, dependable joiners that hold our planes, cars and spacecraft together (among other things).

Here are eight examples where 3D printing enabled a better bracket:

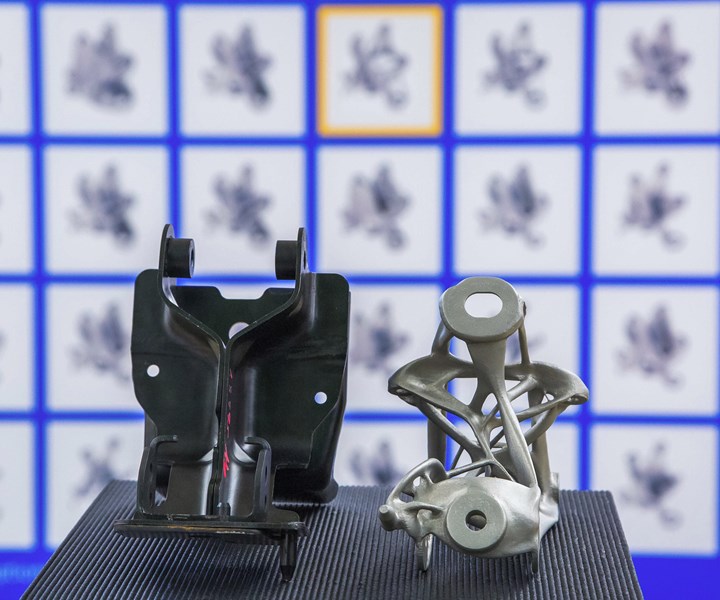

1. A stronger car seat bracket.

GM and Autodesk engineers collaborated to create this generatively designed seat bracket, which consolidates eight different parts into one. The 3D printed bracket is 40% lighter and 20% stronger than its predecessor.

2. Utilizing previously unused space.

This bracket 3D printed for the U.S. Army Aviation and Missile Research Development and Engineering Center (AMRDEC) effectively replaces a more conventionally shaped bracket by reconfiguring how the bracket’s mass is spread in space.

3. Lighter satellites.

A satellite bracket redesigned by Airbus reduced the amount of material needed, lowering the weight of each satellite by 1 kilogram.

4. A nonmetal mounting solution.

When Boyce Technologies undertook a rush job to build kiosks for the NYC Transit, the company had to quickly come up with a way to mount LED lights inside without disrupting the reception of a sensitive antenna. Plastic brackets 3D printed in just the right shape offered a fast and cost-effective solution.

5. A more efficient jet engine.

The winning entry in GE’s jet engine bracket challenge reduced the mass of a conventional bracket by more than 80%, balancing strength and stiffness in a lighter weight design.

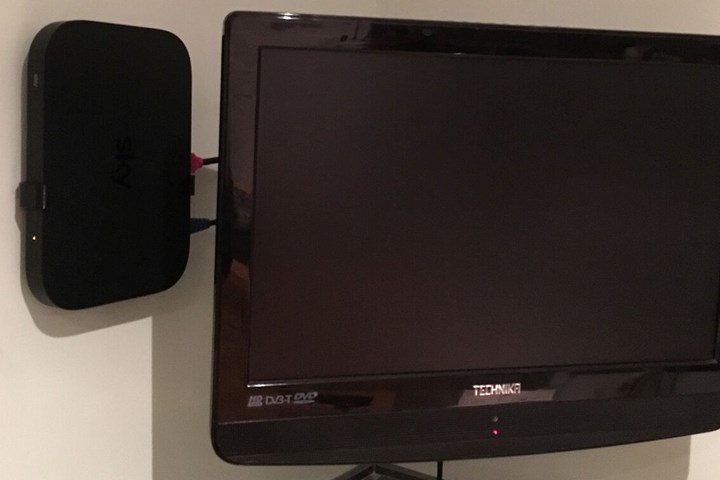

6. More sustainable mount for household electronics.

Pengraff UK has built its business providing mounting solutions for routers and telecommunications equipment, hardware with built-in obsolescence. 3D printing these brackets from recycled filament enables the company to live its values while manufacturing products with a limited lifespan.

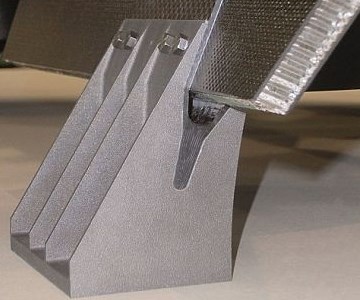

7. An assist to lights-out machining.

Precision Tool Technologies has built its own automated coolant system which it plans to market to other machine shops. Key to this system? 3D printed brackets customized to each machine tool.

8. Faster path to satellite parts.

Machining 12 of these antenna shear tie fittings out of solid block would have taken 425 hours, but additively manufacturing them took just 220.

Show us your brackets!

Do you have an interesting, innovative or just plain weird bracket example? Tell us about it! Email me or tweet @AM_StephanieH.

Related Content

-

8 Social Media Posts About Additive Manufacturing: AM Radio #34

Cost savings, modifications, large-format AM and more. In this episode of AM Radio, we discuss what people are saying about additive manufacturing on social media.

-

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

-

Faster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

.jpg;width=70;height=70;mode=crop)