Ultem, PEEK or PEKK? Choosing Between High-Temperature Plastics

How do you choose between these high-performance materials? A conversation with Arkema and Plural AM sheds light on 3D printing with these polymers.

High-performance polymers like PEI, PEEK and PEKK offer many benefits, but only when they are matched to the right printer capabilities. This fluid distribution manifold, shelf bracket and electrical wiring holder were all printed from Kepstan, a PEKK material supplied by Arkema. Image credits: Arkema

High-temperature plastics such as PEEK and PEI (Ultem, for example) have become the darlings of the additive manufacturing (AM) world in recent years. Parts 3D-printed from these high-performance polymers have been launched into space, used in low contact medical applications and cleared for use in aircraft. In designing or redesigning a part to be 3D printed, engineers might be tempted to lean toward these materials.

But are they always necessary? Should a new part automatically be built from one of these?

Welcome! You’ve unlocked premium content.

No, say 3ntr printer distributor Plural AM and Arkema, a materials supplier offering 3D printing polymers. The two companies have been collaborating for the past several years to understand relationships between fused filament fabrication (FFF) 3D printers and materials, most recently giving a joint presentation on this topic at the 2019 AMUG Conference.

“Sometimes people say, ‘I need Ultem’ or ‘I need PEEK,’ because they use that material in other applications,” says Ed Israel, president and co-founder of Plural AM. “However, if the part doesn’t require FAA or medical certification, then comparable materials may be easier to process.”

In such cases, there is a risk of not just overengineering the part in terms of material but actually introducing added difficulty and expense in manufacturing. The key is to understand the specific attributes needed in an application for a high-performance polymer, such as high temperature resistance, chemical resistance or anti-flammability.

Challenges with PEI and PEEK

“Polyetherimide (PEI) materials such as Ultem and PEEK go in what I would call the ‘cranky category,’” Israel explains. “For the best precision, the materials need high-temperature build chambers generally over 100°C and can take 30 minutes or longer to heat up. The materials are more troublesome to print with accurately because they are hygroscopic, isotropic and prone to warping.”

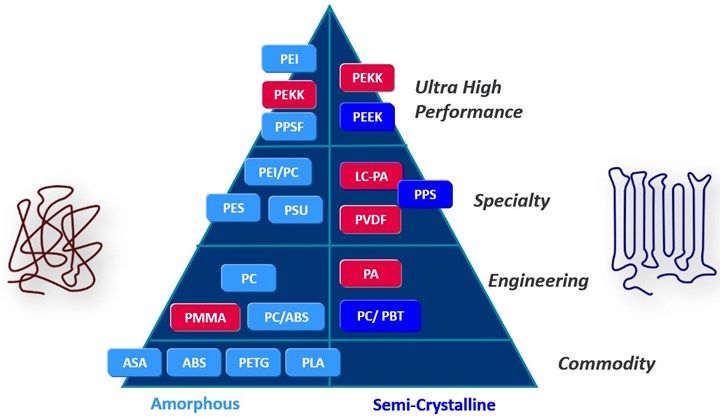

A depiction of amorphous and semicrystalline polymers commonly used in fused filament fabrication (FFF) 3D printing.

The key characteristic that makes PEI materials difficult to print is their high glass transition temperature (Tg), explains Rod Reber, senior engineer at Arkema. Ultem, for instance, has a glass transition temperature over 200°C. The material must be extruded well above the glass transition temperature, but then will cool to the temperature of the build chamber, potentially causing shrinkage.

“Any build chamber not near the glass transition temperature will give you thermal contraction from 200°C down to the chamber temperature,” Reber says. “Printing PEI works well if you go through the extra engineering required to get your build environment really hot (typically above 100°C). Otherwise you will have all sorts of problems with warping.”

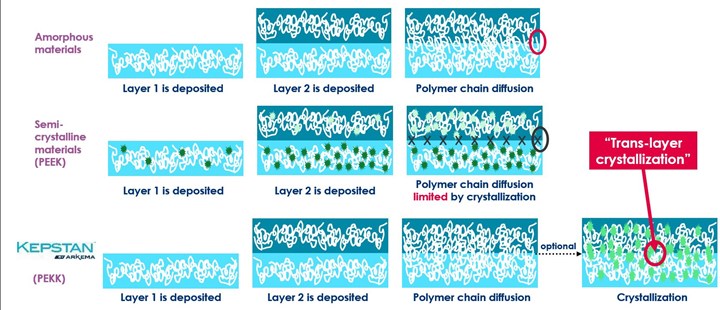

Things get even trickier with PEEK. Where PEI is an amorphous material, meaning polymer chains can fuse across layers for near-isotropic properties, PEEK is semicrystalline with sections of polymer chains that align into a crystalline structure as the material cools, introducing another challenge. If the crystalline structure cools too rapidly, it creates additional thermal stress and more warping.

The challenges of printing PEEK with a lower build chamber temperature can be countered with fiber reinforcement in the material, which helps fight shrinkage, or with post-print annealing in an oven, but these also add complexity to the production process.

The implication is that just because a high-temperature material can be extruded by a 3D printer, doesn’t mean that parts will be dimensionally accurate. Depending on the material and the build chamber temperature, parts can still experience warping and dimensional shift. How can manufacturers handle these challenges with an existing 3D printer if the build chamber isn’t hot enough to print these high-temperature polymers?

The PEKK Alternative

PEI and PEEK aren’t the only option for high-strength, high-performance parts. For printers with a lower build chamber temperature (generally less than 200°C), PEKK can be a valuable alternative in applications requiring attributes such as mechanical strength or temperature resistance.

Like PEEK, PEKK is part of the polyaryletherketone family of semicrystalline polymers. “The main difference is that PEKK has a much lower crystallization rate, so it can be processed like an amorphous polymer,” Reber says. That means the thermoplastic is less affected by cooling in a lower-temperature build chamber, so it has better layer adhesion and less warping.

In amorphous PEI materials, polymer chains can diffuse across layers. In semicrystalline materials, this diffusion is limited by the formation of crystalline structures as the material cools. PEKK materials such as Kepstan from Arkema crystallize at a lower rate, allowing for better layer adhesion.

“That’s what interested us in PEKK,” Israel says. “We can print it with 3ntr printers and get 90% of the strength that printing it in a higher temperature chamber would give.”

Compared to PEI, PEKK is stiffer but offers comparable flammability and chemical resistance. For applications that don’t require specific certifications, or where an appropriate high-temperature printer chamber is not available, PEKK offers a means of manufacturing strong polymer parts in a more predictable process at a lower build chamber temperature.

The best-case scenario, Israel says, is to let the application requirements determine the material — and then select the 3D printer.

“...you’ve got to have the right combination of printer, environment and temperatures.”

“Every single material has its own set of properties and characteristics that it professes in the market,” he says. “But to achieve best performance, you’ve got to have the right combination of printer, environment and temperatures. Once you define the application and then the material, then you know you’re going to have a limited number of printers to choose from.”

Read Next

Orion Gets a Lift from Electro-Static Dissipative (ESD) Material

NASA’s Orion spacecraft will include parts 3D-printed from electro-static dissipative Antero 800NA from Stratasys. Developing this material was an exercise in working within constraints.

Read MoreHow Does Additive Manufacturing Complement Injection Molding?

The Additive Manufacturing Workshop for Plastics, held during Amerimold 2019, offered a platform for industry experts and mold builders to discuss how AM can complement injection molding and what it takes to transition from prototyping to high-volume production.

Read MoreVideo: This Custom Part Illustrates the Promise of Polymer 3D Printing

A low-quantity plastic part used instead of metal components saved weight for a motorcycle. The application illustrates the expanding opportunities for polymer manufacturing.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=150;quality=70)

.jpg;maxWidth=400;quality=70)