Injection Molding with the Geometric Complexity of 3D Printing

The Freeform Injection Molding (FIM) process from Addifab allows for injection molding resins to be processed into shapes not otherwise possible.

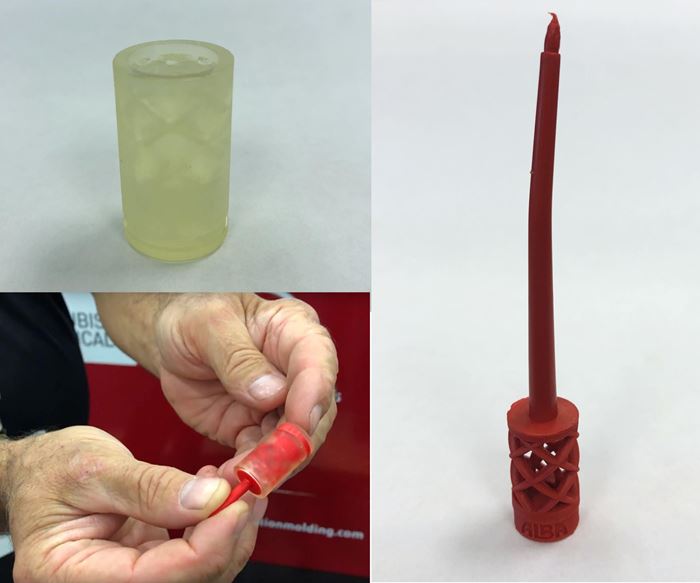

Parts made with a new molding process called Freeform Injection Molding (FIM) often do not resemble conventional injection molded parts. Many of those on display at Rapid + TCT 2019, where the process made its U.S. debut, had complex internal features, lattice structures and other characteristics more commonly associated with 3D printing. But the parts were injection molded. Developed by Denmark-based Addifab, the FIM process uses 3D printed tooling to injection mold parts with seemingly impossible geometries.

Here’s how the process works: First a mold core or cavity insert is 3D printed with a stereolithography (SLA) printer using a proprietary resin, both developed by Addifab. That 3D printed insert is then incorporated in a mold within a standard injection molding press and shot with an injection molding resin. The part comes out of the press with the 3D printed portion of the mold still intact; this sacrificial tooling is then removed, leaving behind the final part. While the 3D-printed insert can be used only a single time, this temporary tooling is strong enough to process high-temperature polymers and can even be used for metal injection molding (MIM).

Why not print the part directly? According to Lasse Staal, Addifab cofounder and CEO, the reason is materials. FIM offers the design freedom of 3D printing with the accepted material portfolio of injection molding. That gives users far more options in terms of final material, and avoids the challenges with qualifying and troubleshooting new 3D printing materials.

At Rapid + TCT 2019, Addifab emphasized the material freedom of its process by co-exhibiting with Mitsubishi Chemical. “We are able to convert more than 5,000 of their stock materials and grades already today,” says Carsten Jarfelt, CEO for Addifab Inc., the company’s U.S.-based arm.

Addifab is currently offering a startup package consisting of 3D printer, resin and a Babyplast injection molding press from Alba Enterprises. This smaller press is the ideal size for tools made in the printer’s 2 by 4 by 8-inch build volume, Staal says.

Applications for FIM include spare parts, legacy parts, audio and electronics, and industrial components. The process is especially suited to parts with complex geometry, overmolding or other special features. One example on display at the show was a connector for Danfoss compressors. The main body of the part was shot from carbon-fiber filled material in a 3D printed FIM mold. Then, a modified mold was used to overmold the TPU ring, which is mechanically held in place; the material flows through several small holes in the initial molded part and leaves a small deposit of material on the other side with no assembly or glue required.

More broadly, FIM is a way of getting products to market faster. 3D printed mold tooling is faster to produce, making it easier and cheaper to iterate designs—a key advantage especially for newer companies. “This is time compression on the project level,” Jarfelt says. “Startups shouldn’t die because of lack of manufacturing options.”

.jpg;width=70;height=70;mode=crop)