Articles

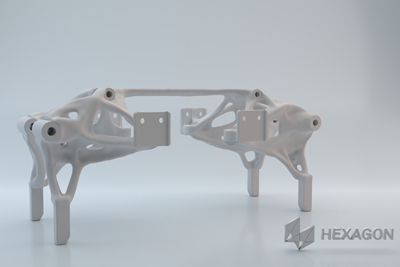

Improving AM’s Efficiency with Generative Design

By engineering parts as opposed to designing them, MSC Apex Generative Design improves the efficiency of not only the final parts, but of the design and manufacturing processes as well.

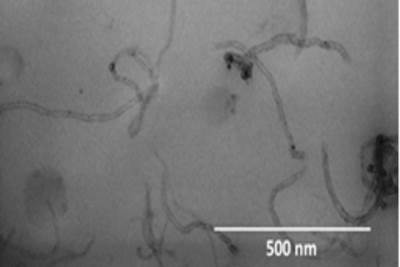

Read MoreUntangling the Promise of Carbon Nanotubes for 3D Printing

Recently emerged from stealth mode, Mechnano is bringing the promise of carbon nanotubes (CNTs) to life within various modalities of 3D printing. How these tiny additives deliver macro-level material improvements.

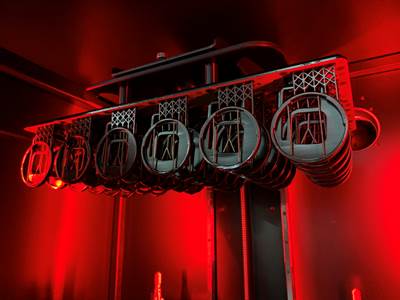

Read More3D Printed Cooling Bars Will Improve Observability of Antimatter

An experiment at CERN’s Large Hadron Collider (LHC) will be better able to detect the paths of particles thanks to efficient cooling delivered by metal 3D printed tubes.

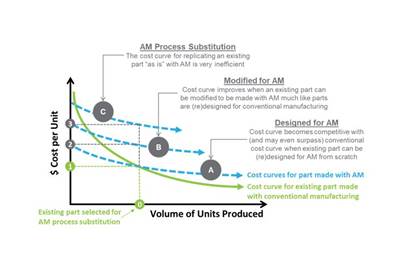

Read MoreIs AM in Competition With Conventional Manufacturing? Tooling Is on Conventional’s Side

Recent articles consider the other way additive manufacturing is advancing production: not by 3D printing parts, but in the ways 3D printed tooling makes casting, machining, molding and other processes better.

Read MoreMore Examples of How 3D Printed Tooling Is Transforming Part Production

Illustrations of successes with tooling made through additive manufacturing in applications involving composite parts, robots, metal coating, die casting and construction.

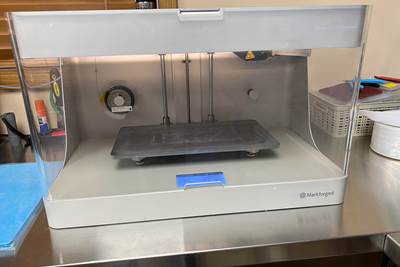

Read MoreMetal and Composite AM Grant US Army Significant Savings

Markforged’s printers and proprietary Eiger software have enabled the U.S. Army to save over $9,000 per part for some critical training components.

Read MoreFord is Saving Millions through 3D Printing (But Maybe Not How You Think)

Two longtime workers at Ford’s Sharonville Transmission Plant near Cincinnati grew tired of experiencing the delays and downtime resulting from expensive and hard-to-get replacement parts. The solution? Learn additive manufacturing and save the company time and money.

Read MoreOil Collector Upgrade for Legacy Helicopters Is a 3D Printed Pathfinder Part

The lightweight part was delivered faster and made more easily via electron beam melting (EBM) than a conventionally manufactured alternative could be produced, while also illuminating a way forward for upgrading other existing systems.

Read MorePolymer AM Cuts Costs of Small-Batch Replacement Components

Producing replacement parts through polymer AM has cut Mosca’s lead times and component costs to small fractions of their original size, even when producing small batches of parts.

Read MoreAfter Years in China, 3D Printing Lets Vacuum Accessory Maker Develop U.S. Production

The costs of injection molding had Dustless Technologies making tooling and many parts offshore. Additive manufacturing promises an alternative, as in the case of the company's newest product, which is entirely U.S.-made.

Read MoreJob Shop’s AM Journey Takes It from Production to Tooling

Despite the fact that RPG was prepared to start with production metal additive manufacturing, the job shop couldn’t ignore the benefits of 3D-printed tooling.

Read More