Articles

Another Giant Leap for AM — New Standards

Did anyone notice how many AM standards got approved during the pandemic?

Read MoreWhat Distinguishes Additive Manufacturing?

Is a 3D printer just a machine tool working in reverse? Or is it something else entirely? Stephanie Hendrixson, Peter Zelinski and Julia Hider discuss in this episode of AM Radio.

Read MoreAutomotive Tech Center Sees Benefits and Challenges of AM

The Nissan Technical Center leads Nissan’s work with additive manufacturing. While it has found uses for AM, it maintains a cautious approach to what the technology can currently accomplish.

Read MoreIntroducing AM Radio, a Podcast from Additive Manufacturing Media

Additive Manufacturing Media editors explore 3D printing success stories, AM trends and more on this new podcast. Subscribe now!

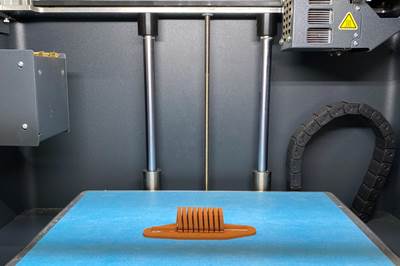

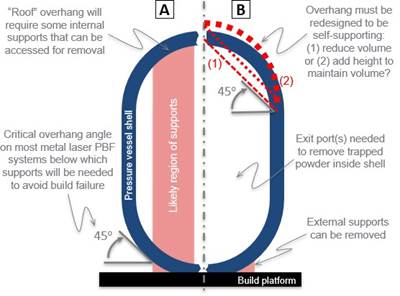

ListenImproving Metal 3D Printing Processes by Reducing Support Structures

SLM Solutions’ Free Float program reduces the need for support structures, decreasing build time and powder usage, improving part quality, opening up space for more parts and giving users more design freedom.

Read MoreFluid Dynamics Software Optimizes Duct Airflow, Saves Energy

Siemens’ Star CCM+ fluid dynamics software enabled Siemens and HP to optimize the air flow within a 3D printed air duct for cooling HP’s Multi Jet Fusion printers.

Read MoreEstablishing a Process for 3D Printing Carbide

Using its experience making pressed and sintered carbide parts, Hyperion Materials & Technologies developed a new material, printing processes and sintering cycles for 3D printed carbide.

Read MoreAM Center Supports Automotive Supplier's Greener Engine Plan

Automotive supplier Mahle has invested in an additive manufacturing center, saying the technology will support development in thermal management, mechatronics and electronics to produce more environmentally friendly engines.

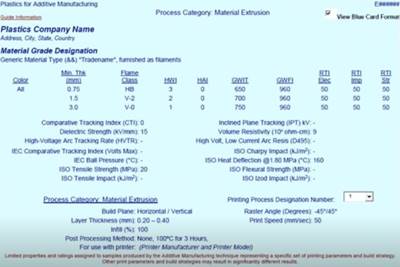

Read MoreAM Material Certification Database Cuts Redundant Testing

UL’s Blue Card program provides a reliable, transferrable set of test results for plastic materials used in additive manufacturing — so long as the user’s printing parameters match the tested parameters.

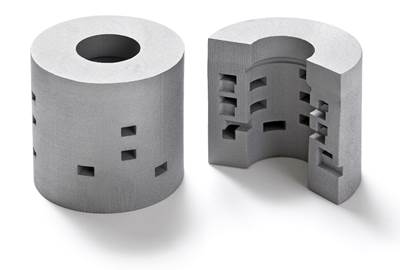

Read MoreOne Small Step for Metals, One Giant Leap for AM

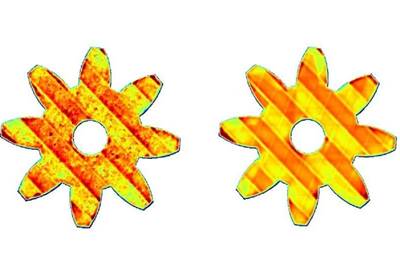

Eliminating support structures for metal parts expands pathways to profitable AM.

Read MoreWhy Self-Supervised Deep Learning May Be Additive Manufacturing's AI Solution

In collaboration with equipment supplier EOS, artificial intelligence experts at NNAISENSE have created a self-taught “deep digital twin” to advance additive manufacturing, starting with direct metal laser sintering of titanium.

Read MoreWith Binder Jet Aluminum, Ford Prepares for Production 3D Printing at Automotive Scale

Component for popular car will be the first case of continuing applications of additive manufacturing to automotive-quantity metal part production.

Read More