Articles

8 Cool Parts From RAPID+TCT 2021: The Cool Parts Show #32

North America’s largest AM trade show resumed! Here are some of the coolest cool parts we found.

WatchImpressions and Trends from RAPID + TCT 2021: AM Radio Bonus

Peter Zelinski, Stephanie Hendrixson and Julia Hider discuss what they saw, heard and learned at RAPID + TCT 2021 in a special episode of the AM Radio podcast plus slideshow.

ListenExpanding Materials, Applications for Inkjet 3D Printing

Traditionally, the materials available for inkjet 3D printing have prevented the process from being used in production of end-use parts. But machine vision systems and AI are broadening the materials and applications for inkjet 3D printing.

Read MoreMicro 3D Printing Slashes Costs, Lead Time for Medical Part

Micro 3D printing enabled AntiShock to produce a small-dimension, high-detail part with greater accuracy than SLA and at 20% of the cost of CNC production.

Read MoreHow Is Additive Manufacturing Sustainable? AM Radio #2B

Additive manufacturing is often closely associated with sustainability, but why? And how can companies use AM to develop sustainable processes? Stephanie Hendrixson and Julia Hider discuss in this episode of AM Radio.

ListenGenetic Engineering for Metal: The Promise of Microstructure Control via Additive Manufacturing

“To design the alloy, design the microstructure,” says this Ohio materials science startup. Artificial intelligence is helping to realize a design tool for determining the properties of 3D printed metals.

Read MoreWhy Do So Many Additive Manufacturers Build Their Own 3D Printers? AM Radio #2A

It's not unusual for companies making parts and products through 3D printing to also develop the printers they use to do so. Stephanie Hendrixson and Julia Hider share examples and discuss why this happens on the latest episode of AM Radio.

ListenThe Coolest Cool Parts

Season 5 of The Cool Parts Show is on the way — but before it premieres, revisit some of the team’s favorite episodes so far.

WatchCustom Heels Are a Step Up for Circular Fashion, Sustainable Manufacturing

Custom shoe company Hilos demonstrates how, with additive manufacturing, relative outsiders can not only launch a product, but implement a new production mindset into an established industry. The company is bringing comfort and customization to fashion footwear with sustainable, on-demand production based on 3D printing.

Read MoreDoes 3D Printing Drive Startups, or Vice-Versa? AM Radio #1

What is it about 3D printing that makes it such a common choice for startup companies? Are these businesses driving additive manufacturing forward, or are they being driven? Peter Zelinski, Stephanie Hendrixson and Julia Hider discuss.

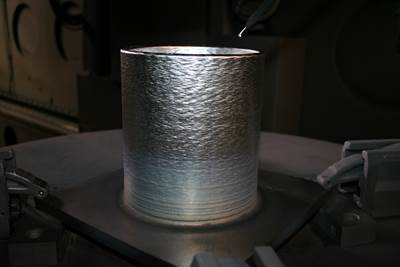

ListenAI to Aid Consistency in Electron Beam Additive Manufacturing

Machine vision and algorithms have helped EBAM users address problems as they occur in deposition, but AI could be able to predict problems before they happen.

Read More4 Ways Robots and 3D Printing Intersect

Four examples of how robotic automation and additive manufacturing both help and are helped by each other.

Read More