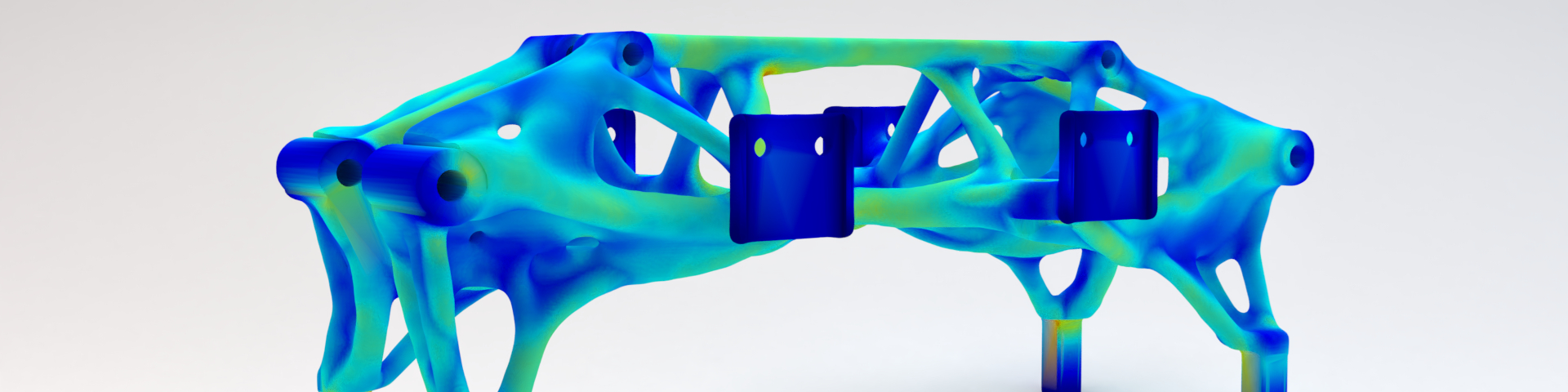

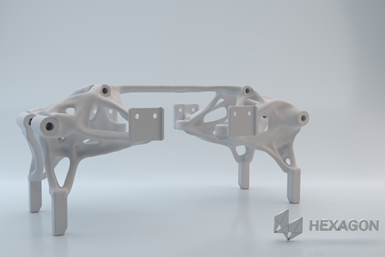

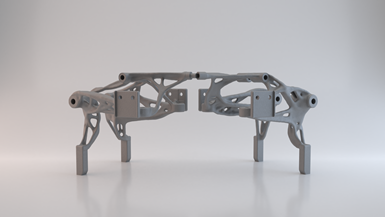

MSC Apex Generative Design engineers parts instead of designing them, reducing design time for additive manufactured parts by as much as 80%, according to the company. Photo Credit: Hexagon Manufacturing Intelligence

We tend to think of the efficiency of additive manufacturing (AM) in terms of the function of the part — which can be more lightweight and therefore more efficient — or in the reduction of steps or time due to, say, assembly consolidation. But parts that are more efficient in these ways are more complex, and therefore potentially harder to design. “Efficiency should account for the manufacturing process and the design process as well,” notes Dr. Thomas Reiher, director of generative design at Hexagon’s Manufacturing Intelligence division. Improving efficiency in all areas, including the role of design engineering, enables companies to develop parts that are cheaper and can be brought to market faster.

Topology optimization and generative design programs can help improve efficiency when it comes to designing parts for AM, but it can take hours for one of these systems to calculate all of the design possibilities for a part, and then sort through potentially thousands of candidates and eliminate the ones that won’t work, either because they are geometrically or mechanically unsuited, or because of manufacturability concerns.

Reiher and his team at Hexagon are working to solve these issues with MSC Apex Generative Design (MSC ApexGD). Through what the team describes as engineering the parts instead of just designing them, the program improves not only the efficiency of the end parts, but the efficiency of the design and selection process as well, reducing design time by as much as 80%, according to the company.

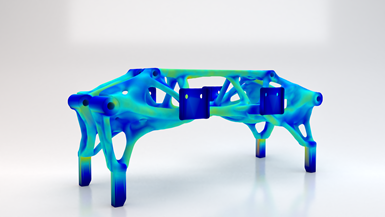

MSC Apex GD runs stress-based optimizations that look at the geometry of the part and the loads on it. It reduces as much material as possible while still ensuring the part can withstand the required loads, and evenly distributes stresses across the part. Photo Credit: Hexagon Manufacturing Intelligence

Less is More

By “engineering” the parts, MSC ApexGD produces fewer results than traditional topology optimization programs. But having more options isn’t necessarily better. Producing thousands of design candidates can take a significant amount of time. “We want to make sure that you're not wasting time, even if it's cloud computing time,” Reiher says. Having fewer high-quality options also saves users time when evaluating design candidates. “We are putting out just those designs which really fit the needs,” he explains. In order to accomplish this, users are asked to set up additional parameters beyond the typical elements such as design areas, non-design areas, boundary conditions and fixed constraints.

The most important parameter in helping eliminate invalid design candidates, according to Reiher, is the stress goal. This is because MSC ApexGD runs stress-based optimizations that look at the geometry of the part and the loads on it. It reduces as much material as possible while still ensuring the part can withstand the required loads, and evenly distributes stresses across the part.

Users can also control the complexity of the final design with a parameter called strut density. Selecting “sparse” will result in a simpler part with fewer, thicker struts, while “dense” will produce complex parts with lots of thinner struts. Reiher says this also helps streamline the design process. “The engineer is not asked just to set up some weird mathematical values,” he notes. “They should think about how they want the part to look. Do I want a high complexity with a lot of struts, or do I want something easy to clean, so less struts? And then with the parameters, you can influence the design.”

Another time-saving feature in MSC ApexGD is the ability to add extra material for machining allowance. Traditional topology optimization requires users to manually add additional material to machined features, such as screw holes and bearing seals, before the part can be sent to the printer. MSC ApexGD can automatically add this material to the model, and then generates two part files — one that represents what the part will look like after printing (with extra material on the surfaces that will be machined), and one of the final part (after the extra material is machined away). The final part geometry can be used for stress testing and programming the machine tool, while the first file is ready to be sent to AM simulation programs to confirm manufacturability.

Because MSC ApexGD is under the Hexagon Manufacturing Intelligence umbrella, it’s easy to integrate it in a larger additive manufacturing process. “In general, we want to make sure that we do have one closed workflow,” Reiher explains. The team is still working on this goal, but for now, users can easily import and export data between other Hexagon software programs, including its Adams multibody dynamics software for stress simulations and MSC Nastran for structural analysis. Then, when the model is ready, it can then be sent from MSC ApexGD to Simufact Additive for metal AM process verification or Digimat AM for polymer AM verification. “Then you can be sure that you do have a part that is structurally optimal and optimized for manufacturing,” he says.

From the Cloud to the Computer

Traditionally, in order to produce the potentially thousands of design candidates, generative design and topology optimization programs require the computing power of the cloud. According to Reiher, this is a waste of time and energy. MSC ApexGD users still have the option to run the program in the cloud, but it is designed to run on a CAE workstation or a laptop with a graphics card. In order to do this, the development team needed to ensure that models were being set up in the right way, so they could be easily and quickly consumed by the GPU. The company used various strategies to accomplish this:

- When going from one design iteration to another, the software’s algorithm only preserves the material from the previous iteration. It doesn’t go back, move the material around and calculate additional models from there, like traditional topology optimization programs. “We are really throwing out the elements we don't need,” Reiher says, “so we are reducing the amount of needed calculations.”

- The software uses low-resolution models at the beginning of the optimization process. This is when the program is working out where the material should be more generally, and it doesn’t need all of the details of a high-resolution model — they just slow the program down. But as MSC ApexGD goes through the optimization process, it gradually adds more details until the final result is a high-resolution model. “With this, we are saving a lot of calculation effort,” he notes.

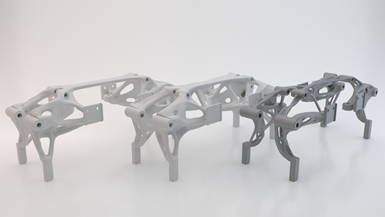

Users can interact with the model during the optimization process. For example, this user optimized a polymer gripper housing (left), but wanted to add an extra strut (middle). It also produced a metal version of the gripper housing (right), using the optimized polymer part as a starting point. Photo Credit: Hexagon Manufacturing Intelligence

Running on a laptop not only saves time from not having to send the data to and from the cloud, it’s also safer because it’s contained locally on a machine. Reiher says it also gives users better access to the optimization process, enabling them to interact with it. For example, after the program has been running for a few minutes, users will be able to determine if the design is going in the right direction. If they do notice an issue with the model — for example, a disconnected strut or a missing attachment point — they can go back to the model setup and adjust the parameters as needed. The optimization will continue from the last stopping point, adjusting the structure to account for the changes. “We can really work interactively with the optimization, starting it, seeing how it evolves, then stopping and starting again,” he explains. This allows users to save time by correcting problems early in the design optimization process.

Case Studies

Not only has MSC ApexGD enabled users to produce parts with significant weight reductions, but it’s also been able to do this in significantly less time than other programs.

MSC Apex GD is designed to run on a CAE workstation or a laptop with a graphics card, instead of in the cloud like traditional generative design and topology optimization programs. This saves time by not sending the data to and from the cloud, is safer because data is contained locally on a machine and enables users to interact with the model during optimization. Photo Credit: Hexagon Manufacturing Intelligence

One of these successes involves a polymer gripper housing for Schubert, a German company that manufactures packaging machines. The original part design was too heavy and not stiff enough, so the company turned to MSC ApexGD to redesign it. The program was able to produce an initial optimized part within 18 minutes. “I don’t mention this very often because it looks very unbelievable,” Reiher says. “But yes, I've seen the files.” In a traditional topology optimization program, he estimates this would have taken anywhere from four to 10 hours. After reviewing the optimized design, team members wanted to add an additional strut. They manually added the feature and ran it through the optimization process again. The part that resulted was only slightly heavier than the initial optimized part, as material was taken from elsewhere on the part to make up for the extra strut. This final part weighs 56% less than the original part, and is four times stiffer. Schubert was also able to design another version of the gripper in metal, using the polymer design as a starting point.

Reiher also gives the example of a medical implant for a radius arm bone. The original design was too heavy, and patients could feel the added weight in their arms. The customer wanted to re-design the implant to be lighter, but still strong enough the handle the loads of patients lifting and carrying things. It investigated realistic load cases for the arm, and used this data to optimize the design in MSC ApexGD. The program generated a new, fully engineered and print-ready design within hours. It’s 63% lighter than the original, and can be printed in one piece instead of consisting of multiple pieces like the original. It also has the added benefit of a lattice structure, which enables muscles and bone to attach to the implant.

Related Content

Decentralized Manufacturing Network Aims to Make 3D Printers a Shared Global Resource

The 3DOS additive manufacturing network will let OEMs and creators take advantage of open 3D printer capacity anywhere in the world.

Read More3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreOvercoming the Bottleneck to Customized Manufacturing: Quoting

Spokbee’s software-as-a-service platform is shaving months off of the quoting and pricing process for 3D printed and other types of configurable products.

Read MoreRead Next

Video: Topology Optimization versus Generative Design

Why do these strategies matter in design for additive manufacturing (DFAM), and what’s the difference? A conversation with PADT’s Eric Miller explores AM and design, including its human element.

Read MoreGenerative Design to Bring Weight and Cost Savings for Micromobility FUV

The “Fun Utility Vehicle” from Arcimoto is already in production, and already lightweight. But after just 30 days of redesign for additive manufacturing, the company discovered major components could be made lighter still, and production could be made simpler.

Read MoreGM Seat Bracket Made with Autodesk Generative Design Software

The bracket is the result of a multi-year alliance between the two companies to explore generative design, AM and materials science for vehicle lightweighting.

Read More