Articles

How Do You Make a Howitzer Less Heavy?

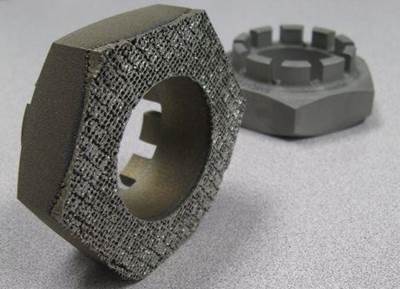

Large nuts that used to be solid metal are now grown with a honeycomb structure on the inside for valuable weight savings.

Read MoreCracking the Code to Growth in AM

It takes more than machines on the shop floor to push additive manufacturing to the next level. According to one manufacturer, it takes customer service, education and training, too.

Read MoreLearning Curve

A manufacturer that has succeeded for three generations expects additive manufacturing to be part of the reason why it will succeed in the fourth. One year into its investment in the technology, here is the company’s experience so far.

Read MoreRedEye to Join with Other Additive Manufacturing Companies

Stratasys, the supplier of additive manufacturing technology and also owner of additive manufacturing service provider RedEye, announced this week that it intends to acquire two other AM service providers: Solid Concepts and Harvest Technologies.

Read MoreVideo: 3D Printing with Carbon Fiber

Make parts as strong as metal on a desktop machine, the company says.

WatchWhy Make a Bike Frame through Additive Manufacturing?

One reason to make a bike frame through additive manufacturing processes is that unnecessary weight disappears. The 3D printed frame is two-thirds the weight of the previous version. Other advantages relate to design freedom and the performance of the additively applied alloy.

Read MoreAdd-On Additive Manufacturing

The capacity to build 3D metal forms is a retrofittable option for subtractive CNC machine tools.

Read MoreVideo: Additive Manufacturing in Extreme Application

NASA’s test of a rocket engine fuel injector made through selective laser melting illustrates an additively produced part’s capacity to perform at high temperature and pressure.

WatchOn Pinterest: Design for Additive Manufacturing

Arguably the most important thing to know about additive manufacturing is that it changes the rules of design. See how a Pinterest user is making this point.

Read MoreSand Printing’s Side Benefit

A pattern maker is now able to skip the pattern by printing foundry mold components directly in sand. This figurine is a byproduct of the way the company batches the sand-printing jobs for greater efficiency

Read More3D Printing As an Alternative to Patternmaking

Hoosier Pattern has changed its business in a way that dramatically expands the design freedom available to its customers. Historically, the company has machined foundry patterns. Today, it uses 3D printing to create molds and cores directly from sand.

Read More