How Do You Make a Howitzer Less Heavy?

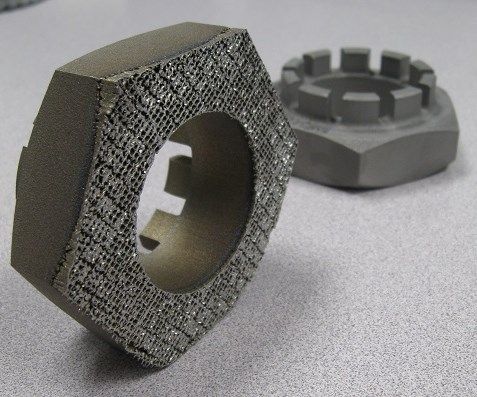

Large nuts that used to be solid metal are now grown with a honeycomb structure on the inside for valuable weight savings.

Manufacturing contractor Imperial Machine & Tool Co. recently found a way to give these engineers some freedom. By replacing solid metal nuts on this gun with nuts composed of a honeycomb structure on the inside (each nut is about as big as the palm of a man’s hand), this shop was able to cut the weight of each of these nuts in half.

The honeycomb nuts were grown through additive manufacturing. They would have been impossible to produce any other way.

Imperial Machine & Tool Co. is a decades-old manufacturer built on CNC machining that sees investment in additive manufacturing as being key to its continued success in the future. Read more about this company’s exploration of AM.

Related Content

-

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

-

Video: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

-

Reusable LOX/Kerosene Engine Completes First Successful Full-System Test Flight

Galactic Energy Space Technology announced the first successful full-system test flight of its Welkin 50-ton reusable LOX/kerosene engine. To date, this is the highest thrust LOX/kerosene engine in the Chinese commercial aerospace playing field which has officially entered the engineering and manufacturing phase.