Add-On Additive Manufacturing

The capacity to build 3D metal forms is a retrofittable option for subtractive CNC machine tools.

What if one of the oldest CNC machines in your shop could become one of the most sophisticated, and also one of the most noteworthy in terms of what it adds to your shop’s capabilities?

Engineering researcher Jason Jones, PhD, says this is part of the promise of the technology he has been involved in developing over the past several years, a technology now marketed by the company he recently cofounded. His company, Hybrid Manufacturing Technologies of Plano, Texas, offers add-on laser cladding capability that can be integrated into existing CNC machine tools. That is, his company offers a way for additive manufacturing to be added to a subtractive CNC machine.

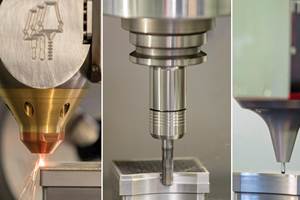

Though adding this process is a significant change, the system integrates gracefully into the existing machine, he says. The head that melts and deposits metal to build 3D forms is stored in the machine’s tool magazine. This head is deployed through G and M codes and loaded using the machine’s toolchanger, and it follows NC tool paths like those of 3D milling. Thus, the machine’s additive and subtractive moves can all be part of a single machine cycle using a single NC program.

What is the value of marrying additive and subtractive processes this closely? The processes need each other, he says. While additive manufacturing makes parts and forms that would be difficult to produce through machining, most metal parts made through additive manufacturing require some kind of follow-up machining, ranging from drilling and tapping holes to finish milling for surface quality. Combining 3D layering and 3D machining into one machine saves time and floor space, and reduces part handling to reduce opportunities for error.

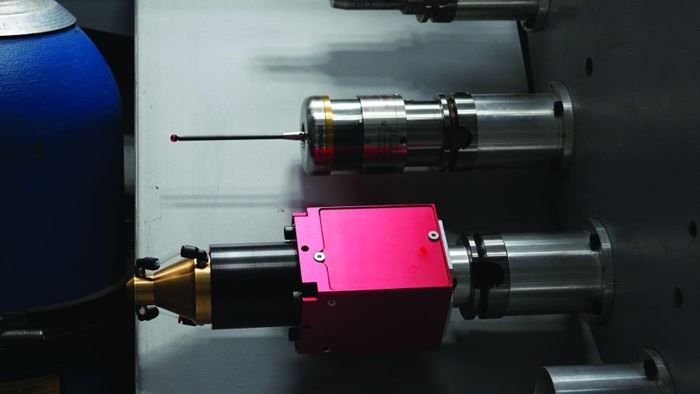

Dr. Jones says making effective use of the marriage of additive and subtractive operations frequently requires a third capability as well: adaptive processing. Particularly in cases in which an existing part is modified or repaired through additive manufacturing, the machine needs to be able to measure the part so it can automatically tailor both the additive build and the corresponding tool paths to the form as it currently exists. Hybrid’s system includes this adaptive capability, employing measurement via Renishaw probes in conjunction with adaptive CAM software developed by Delcam. Both of these companies were involved with Dr. Jones (along with Hybrid’s other cofounder, Peter Coates) in the research that led to the Hybrid system. The UK-based research was initiated by De Montfort University and conducted through the UK’s Manufacturing Technology Centre.

Along with being retrofitted to old machines, the Hybrid system can also be incorporated into new ones. Hamuel Reichenbacher is a machine tool builder that now does this. A maker of five-axis turn-mill machines for turbine blade machining, Hamuel now offers a Hybrid-equipped machine with additive capability. The chief advantage of the capability in this case is that it simplifies blade repair, which is traditionally a manual process. Additive manufacturing on a CNC machine tool enables the repair instead to be made by precisely adding material where needed, then machining it flush—all in a single automated cycle.

Dr. Jones says Hamuel’s machine also brings new possibilities for blade designs with multiple materials. Through additive manufacturing, a metal chosen for its strength and resilience could be augmented with other properties. For greater corrosion resistance and hardness, for example, a surface metal with these properties could be applied to cover the tough base metal.

Related Content

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More5 Points You Might Not Know About Hybrid CNC Machine Tools

Hybrid Manufacturing Technologies’ co-founder describes the role of hybrid additive manufacturing machines, and explores their possibilities related to heat treating, multimaterial tooling and making parts with embedding sensing.

Read MoreJuggerBot 3D Awarded $4 Million by Air Force to Develop Large Format Hybrid Additive System

The project focuses on advancing the ability to print a thermoset composite material that can transform the way an aircraft structure is designed, fabricated and sustained for limited-life aircraft.

Read MoreVideo: Hybrid Manufacturing Without Melting: Hermle’s Metal Powder Application (MPA) Process

The Metal Powder Application (MPA) process uses cold spray to apply metal to an existing workpiece. Because the material deforms rather than melts, MPA opens new possibilities for functional grading and other multimaterial applications.

Read MoreRead Next

Using Hybrid Additive Manufacturing, GE Leverages Turbine Blade Repair into Efficiency Improvement

An engineering modification that would have been impractical or cost-prohibitive in the past is realized on a machine tool performing metal 3D printing and machining in the same cycle.

Read MoreHighlighting Hybrid Manufacturing

The winner of the first International Additive Manufacturing Award is a company that developed a head for adding metal additive manufacturing to an existing machine tool.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More