Mold Tooling

Think Beyond the Machine Tool

A machine jointly developed by GF Machining Solutions and EOS is designed to support mold and die manufacturers.

Read MoreAdditive Manufacturing Makes Subtractive Cutting Tools

Cutting tool manufacturer Mapal leveraged additive technology to produce smaller versions of its through-coolant insert drills.

Read More3D-Printed Tooling Speeds Manufacturing of Cutting Tools

Knight Carbide's insert delivery times had to wait on custom tooling, so they acquired a Mojo desktop 3D printer from Stratasys to make their own. Lead times for insert carriers were shortened from weeks to just six hours.

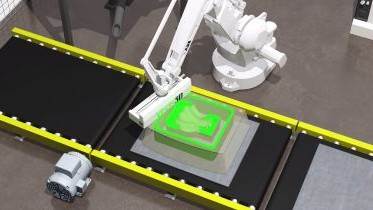

Read MoreVideo: Additive Manufacturing Robot for Foundry Molds

In addition to making either metal or plastic parts, one other production application of additive manufacturing is building in sand to create molds for casting without any need for a pattern.

WatchMultiplying Options

Additive manufacturing’s greatest impact for this company is the versatility that has allowed it to offer different solutions than other manufacturers.

Read MoreWhere Do 3D-Printed Molds Make Sense?

Stratasys describes the capabilities and limitations of 3D “digital ABS” molds for making plastic parts through injection molding or blow molding.

Read MoreRebuild, Don't Replace

If you could rebuild a damaged or worn-out mold insert instead of replacing it with a new one, wouldn’t you?

Read MoreVideo: Additive Manufacturing at Linear Mold

The company uses 3D printing to create conformal-cooling mold inserts in addition to production parts.

WatchVideo: 3D Printing of Injection Molds at Whale

Can plastic be used to mold plastic? This pump maker with in-house injection molding machines talks about how it now makes molds for these machines by printing the molds in plastic.

WatchCracking the Code to Growth in AM

It takes more than machines on the shop floor to push additive manufacturing to the next level. According to one manufacturer, it takes customer service, education and training, too.

Read More