Think Beyond the Machine Tool

A machine jointly developed by GF Machining Solutions and EOS is designed to support mold and die manufacturers.

Share

Read Next

Just when you think you’re caught up with all the methods for conformal cooling and machines for additive manufacturing, you come across a slightly different approach to both. That’s exactly what happened to me during EMO last month when GF Machining Solutions and EOS jointly debuted a new tooling manufacturing solution designed specifically to help optimize the full production of metal mold inserts with conformal cooling. What’s different, you ask? This solution goes beyond the machine.

This collaborative effort aims to offer both machine technology and expertise to support the mold and die communities with their AM endeavors by giving them a system not a single machine. GF Machining and EOS were motivated to develop this solution because they understand that to truly benefit from AM, users need to know everything from design to postprocessing.

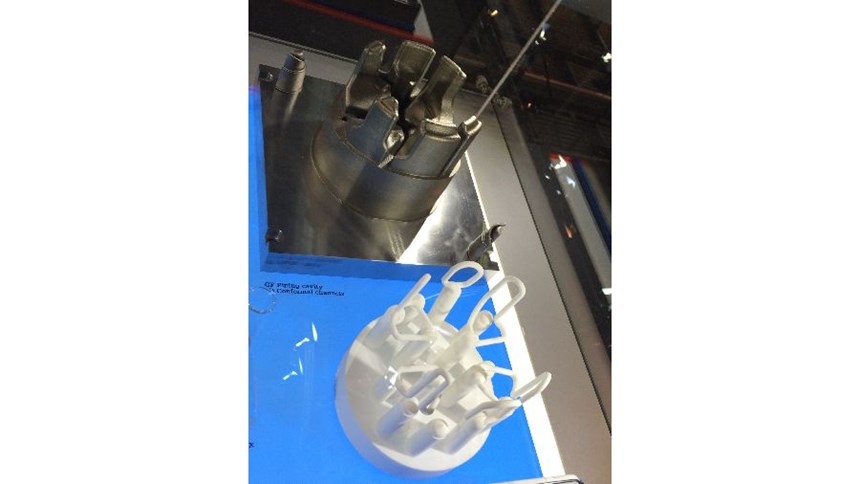

The AgieCharmilles AM S 290 Tooling solution integrates the AM machine, incorporating powder bed-based laser sintering technology from the EOS M 290 system, into an entire production process. This includes the necessary software, automation, required secondary processing equipment (for example, EDM, milling and laser texturing) and measuring devices. The means the moldmaker is working with one source. And all of this is focused only on creating high-quality metal mold inserts with conformal cooling.

According to Gisbert Ledvon, director of business development for GF Machining Solutions, a leading advantage of this joint effort is the quality of the final mold insert. EOS technology separates itself from other AM providers by guaranteeing material quality. EOS provides certified metal powder not only for mold steel similar to H13, but now also stainless steel metal powder. In addition, EOS offers a parameter set that will ensure the material density is 99.95 percent solid. It is heat-treatable similar to other mold steels.

The sintering technology offers freedom of design, which helps shorten cycle times, increase productivity, improve plastic product quality and lower energy consumption. For instance, check out the metal mold insert in the second photo for piping that features thermal exchange close to the surface to ensure and control temperature homogeneity for shorter throughput time and increase part quality.

Related Content

-

Zeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

-

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

-

How 3D Printing Aids Sustainability for Semiconductor Equipment: The Cool Parts Show Bonus

Hittech worked with its customer to replace fully machined semiconductor trays with trays made via DED by Norsk Titanium. The result is dramatic savings in tool consumption and material waste.