Mold Tooling

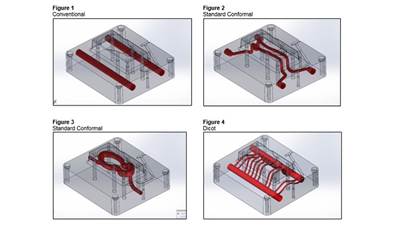

Conformally Cooled Injection Mold Reduces Cooling Time by 55 Percent

With Renishaw’s help, Kärcher ended its production bottleneck using 3D-printed molds with conformal cooling channels.

Read MoreLinear AMS Returns, Retooled and Refocused

After splitting with Moog, the company is getting back to mold tooling and homing in on low-volume plastic part production.

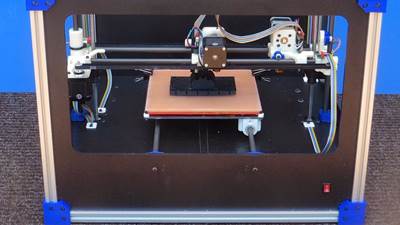

WatchThe Right Design, Material and Machine Combination Takes the Risk Out of 3D Printing Molds

Full-service design and mold delivery, moldmaking materials, and a low-cost, high-precision printer minimize the technical risk of 3D-printed mold tryout.

Read More3D-Printed Prototypes Become the Parts with Carbon Fiber Filled Filament

Utah Trikes, a retailer and manufacturer of trikes and quads, has grown its custom business using FDM Nylon 12CF to produce end-use composite parts that formerly would have required moldmaking.

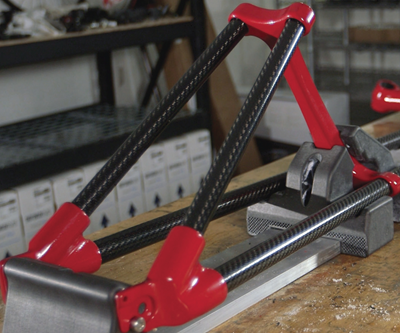

Read More3D-Printed Device Proves Rugged Enough for Dust-Free Tile Removal

Arizona Home Floors considered buying a mold to produce a plastic version of its DustRam product. But when a prototype proved durable enough to withstand working conditions, the production strategy shifted to 3D printing.

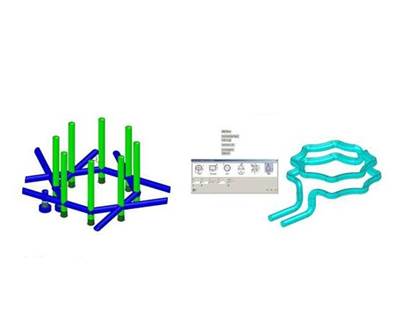

Read MoreDesign Guidelines for Conformal Cooling Water Lines

Additive manufacturing enables complex geometries and nonround cross-sections for conformal cooling lines, but some design lessons from conventionally drilled lines are still relevant.

Read MoreDesign Enhancements for Conformal-Cooled Insert Leverage 3D Printing Capabilities

A collaborative mold project reveals that the value of 3D printing isn’t in the process, it’s in the products.

Read MoreAmerimold 2017 Adds Additive Manufacturing Workshop

The pre-show workshop is just one of the new features of this year’s mold manufacturing event.

Read MoreBiomimicry: Nature’s Way of Cooling Tools with DMLS

Research leveraged biomimicry, a design method based on structures and systems found in nature, to develop a better mold.

Read MoreMolder’s Experience Illustrates How AM Will Interact with Other Advances

Additive manufacturing is not moving forward in isolation. It will leverage and work in harmony with other manufacturing technologies that are also moving forward.

Read More