Multiplying Options

Additive manufacturing’s greatest impact for this company is the versatility that has allowed it to offer different solutions than other manufacturers.

Keith Schneider is a big advocate for additive manufacturing, but he doesn’t expect it to ever completely replace machining in his company’s tool-building process—just enhance it.

“Additive manufacturing is just another process that we have in-house,” says the general manager of Harbec Inc., a New York-based manufacturer of precision plastic and metal products. Since the ’90s, the company has embraced AM as another tool in its toolbox, not some new, up-and-coming technology. It has helped to expand Harbec’s capabilities, offerings and business opportunities when it comes to providing quality, tight-tolerance prototypes, tooling, machined components and injection-molded parts quickly and sustainably.

The company prides itself on helping customers solve complex engineering challenges in product design, development, prototyping or production by providing comprehensive manufacturing services for any stage, and Schneider says AM is key to achieving that goal.

The company has almost always had at least one employee dedicated to working with AM. Fifty percent of that person’s time is R&D, trying to develop the capability and learning where the company should use it. “We have had a whole lot of failures, but a lot of successes as well,” Schneider says.

Today, Jeff Carson is Harbec’s full-time “additive guy.” The mechanical engineer is in charge of developing the company’s current additive technology as well as researching new technology and looking ahead to the future.

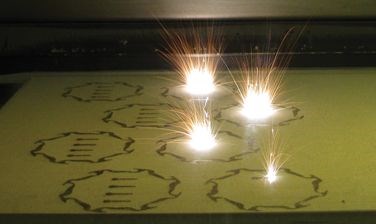

The company first invested in AM in 1996, purchasing a DTM 2500 Plus selective laser sintering (SLS) machine from DTM Systems to make both plastic and metal prototypes. Today, Harbec continues to use AM mostly for prototyping and production mold work, also employing an EOS M270 direct metal laser sintering (DMLS) system and a newly installed Concept Laser M2 LaserCusing machine.

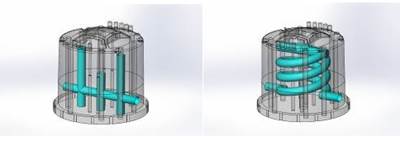

These additive technologies allow Harbec to create geometries that it cannot create with conventional subtractive methods. In the case of mold building, they can be used to create small, internal conformal cooling channels. In part manufacturing, they can create highly detailed, cost-effective parts that would be expensive and time-consuming if built using conventional CNC methods.

Harbec’s sweet spot is complexity. While using additive to make simple parts is cost-prohibitive, the technology tends to offer an advantage for producing complex parts in lower volumes. “Complex parts and tooling are expensive, but AM helps us look at that differently,” Schneider says. “It makes complexity not such a big hurdle, and it also doesn’t have such a cost attributed to it. It’s more about total part volume than complexity.”

To determine if AM is the way to go for a particular job, Schneider recommends a shop review the following three factors:

1. Part complexity. If the part can be easily machined or turned, it is probably not a good candidate for additive manufacturing.

2. Material. While there are a number of AM material options, they are still somewhat limited, and there are some materials that cannot be manufactured additively.

3. Tolerance. Additive machines are accurate, but still not as accurate as CNC machining.

AM has been essential to Harbec’s ability to manufacture complex items, sustain growth, and improve results and pricing for customers. However, the company also has a huge machine shop, so if a customer requires high accuracy on certain portions of a part, it can provide that as a service as well. “We do secondary machining on many additive parts,” Schneider says. “We will take the additive part, grow the majority of it, then load it on a CNC machine to mill any tightly-toleranced features. It’s all about offering customers options.”

Analyze and Evaluate

From the initial quote, Harbec views AM as an option for every project. However, because the company knows that AM doesn’t work for everything, a customer-driven, collaborative evaluation process identifies the best manufacturing option for each individual project.

“Additive is not for everything, and I think some people get lost in that,” Schneider continues. “AM wins from a timeline standpoint, but from a cost standpoint it doesn’t work all the time. That’s where we start to analyze things.”

Harbec has four project managers tasked with evaluating new jobs. When a new project comes in, the project manager determines which process is best and works with the customers on ways to save money and reduce lead times. Customer requirements typically dictate the manufacturing process. “A customer may have a product that could be done at less cost additively, but they want the machined surface finish. Others may want more of an EDM finish, leading us to AM,” Schneider says.

For example, Harbec molds bulk assemblies for a customer that builds interactive model toys. The mold cavity uses conformal cooling, and the company determined that etching on the side of the mold cavity could not be done with traditional CNC machining. “We discussed 3D printing with the customer and decided that growing the mold cavity was the best option,” Schneider says. “We had the tool running in a couple of days, and it is still running today.”

From ABS to Steel

Harbec also offers added value to customers by having both plastic and metal additive manufacturing capabilities in-house, which are incorporated into all facets of its prototyping and mold building.

“I like to tell people that when you come here, there is full accountability. When you bring a project to Harbec, there is only one place to point,” Schneider says.

“We got into plastic additive manufacturing about 14 years ago, so we were on the front end of it. This segment of the technology is pretty busy now, so it is not quite as big a part of our business as it used to be.”

The majority of Harbec’s AM business is prototype parts—short runs of three to five parts up to 20 to 30 parts. The company can reduce the cost of complex parts that would require a lot of machining setups by building them additively.

But it is in mold building that Harbec sees future growth for its AM services because of the savings it can pass on to customers by producing cores and cavities in this way. In addition, the company is exploring producing plastic molds for short-turn prototyping for customers looking to validate design and mechanical integrity.

“We use AM to make complete cavities—everything except the frame of the tool. Basically, the business end of the tool, the part of the mold that interfaces with the molded part and resin,” Schneider says.

Harbec also uses AM to produce production-ready cavities or molds. “We are talking about production tools here, and that is where the cycle-time reduction benefit of conformal cooling comes into play,” Schneider says. “If you reduce cycle time and you are only going to mold a couple hundred parts, it is not that big of a benefit. However, if you are molding a couple hundred thousand or a couple million parts, the time differential makes a significant impact.”

The company’s mission is to provide a wide variety of options to meet its customers’ needs, whether it is for a plastic mold, aluminum mold or steel mold, which usually is determined mainly by part quantity requirements.

One option Harbec offers is direct metal molding using Xyloy metal alloy, a novel technology for injection molding that it uses to produce metal parts more efficiently and cost-effectively than through traditional die-casting or CNC machining. This licensed process creates a part similar to die casting, but without all the drawbacks that go along with casting, according to Schneider. “Basically, it is an injection molding machine with a barrel retrofitted with proprietary heaters and controllers,” he explains. “It molds aluminum and zinc just as you would a thermoplastic resin. It squirts the molten material out of the barrel, cools it in the mold, and it comes out a finished part. There is no secondary infiltration process as you would see with the traditional metal injection molding (MIM) process.”

The resulting parts can hold tolerances of ±0.001 inch without flashing and therefore do not require secondary machining in most cases.

“There are not a lot of people doing this because it is not easy,” Schneider says. “We have been working with the process for about three years. Again, we wanted to offer more options. Currently, the market for it is pretty small, but it’s growing.”

The metal molds Harbec uses for this process are additively grown from a maraging steel material that has outperformed H13 in durability. The molds include cavities and inserts with conformal cooling channels.

The Concept Laser M2 the company recently purchased is used to build mold inserts for conformal cooling. Schneider says this machine is proving to be effective for fine detail and can also run aluminum, which is a primary focus for Harbec right now.

“We are looking at additively growing aluminum molds with conformal cooling,” he says. “Aluminum’s thermal conductivity is already so much greater than steel—imagine adding conformal cooling to that! We also plan to run titanium and a variety of steels.”

Business Benefits

AM also nicely compliments Harbec’s initiatives related to sustainability, real-time collaboration and quick manufacturing solutions.

Sustainability and additive go hand in hand, as there is very little waste involved. The additive process only uses the amount of material necessary to create the part, and the unused powder is recycled. Conventional subtractive methods begin with a large block of material and gradually remove that material until only the part is left. The removed material is discarded in landfills, or melted down and recycled using a large amount of energy. AM, therefore, reduces material consumption and overall energy consumption. In some cases Harbec also has been able to save electricity by using AM instead of EDM.

AM helps support Harbec’s real-time collaboration efforts as well. Project teams collaborate to review, inspect and even modify solid 3D models in real time, and AM prototypes are a part of this review process. Following a kick-off meeting, the 3D printing group prints a model of the part to be manufactured. This becomes a useful reference tool throughout the build to identify areas of concern while also eliminating any communication barriers.

AM also fits nicely into Harbec’s quick manufacturing solutions (QMS), in which creating prototypes and prototype tools quickly is essential. According to Schneider, the company typically can turn around metal or plastic prototype parts in three to five days with AM, but such a fast turnaround is difficult to achieve with a CNC machine.

Plus, with machining, it takes time to get the material in-house and to program, set up and machine the part. With AM, Harbec stocks a number of materials and sometimes can get the part laid out and running in the machine within 30 minutes.

Schneider says AM has also allowed Harbec to take on work that others won’t. “We had a customer who wanted a large, thick-walled part made out of nylon, which is a rather high-shrink material, and they wanted to maintain accuracy so they could have O-rings that would seal. The part was 3/8-inch thick with off-the-charts shrink. We looked at it a variety ways and ended up molding the part with conformal cooling, which allowed us to reduce cycle times significantly.” In this case, AM provided a solution for molding an accurate part and reducing cycle time to an acceptable level for the customer. “If the part had been made through traditional methods, the cycle time would have been much longer, and we are confident that we would not have been able to make it within tolerance,” he says.

Running in Parallel

Where does Harbec see AM taking the company? “Our intent is to have 10 machines running molds for all of our processes, and we are working toward that today,” Schnieber says. This does not mean the company plans to reduce its machining capacity, however. Harbec’s large machine shop has played an immense role in easing employee fears of AM removing machining from the tool-building process. Instead, the company believes AM will work parallel to conventional machining, helping to build better tools, more quickly.

Related Content

Velo3D Founder on the 3 Biggest Challenges of 3D Printing Metal Parts

Velo3D CEO and founder Benny Buller offers this perspective on cost, qualification and ease of development as they apply to the progress of AM adoption in the future.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read MoreSpherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreRead Next

The Marriage of Moldmaking and DMLS

Three factors influenced this molder's decision to use direct metal laser sintering: a decrease in waste, faster mold production and design flexibility.

Read MoreCAM Can Help You Do More with Less

One moldmaker makes significant advances in programming and machining productivity while reducing cutting tool costs.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More