Mold Tooling

New Dates Announced for Amerimold 2021

The premier event for mold manufacturing is now set to take place Sept. 22-23, 2021, at the Donald E. Stephens Convention Center in Rosemont, Illinois.

Read MorePVD Coatings Solve Common 3D-Printed Mold and Part Problems

The right surface modification solution can alleviate a few common additive manufacturing pain points that typically require creating new molds or parts.

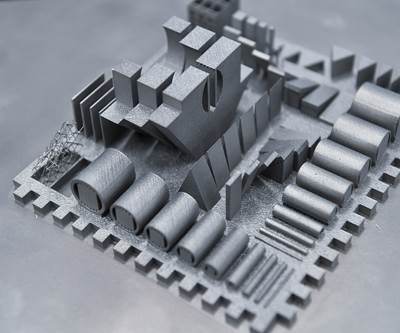

Read MoreTool Steel Alloy Combines 3D Printability with Hardness, Ductility for Tool and Die

Formetrix’s L-40 for powder bed fusion 3D printing enables complex mold geometries at efficient print speeds, with low risk of cracking.

Read More3D Printing and Coronavirus Check-In - Week of 4/13/2020

In this week's update we discuss how additive manufacturing is supporting injection molding for masks, and ramping up to production quantities of face shields and testing swabs.

WatchHoosier Pattern Enables the Design and Print of Intricate Geometries

RAPID 2020: Hoosier Pattern offers the use of 3D printing sand molds and cores that enable users to design and print geometrically intricate designs straight from a CAD file without sacrificing valuable costs and resources.

Read MoreOak Ridge National Laboratory, AddUp Partner on AM for Tooling Applications

Oak Ridge National Laboratory and AddUp have partnered to further additive moldmaking technology for tooling applications.

Read MoreBuilding Confidence in Additive Manufacturing for Tooling

New potential for mold tooling applications is reached with custom-designed materials for additive manufacturing.

Read MoreWatch: Freeform Injection Molding (FIM) Demonstration

Alba Enterprises demonstrates Addifab's Freeform Injection Molding (FIM) process using 3D printed mold inserts at Amerimold 2019.

Read MoreIn Automotive, Is Additive Manufacturing an Answer for Die Cast Tooling?

The largest high-pressure die cast tool builder in North America is 3D printing die inserts and water jackets for major automakers. It’s a tough sell, but one company is succeeding — and it’s just getting started.

Read MoreVideo: Controlled Porosity Can Be Functional Advantage Realized via 3D Printing

A wall of metal that looks solid is actually 90% dense, allowing gas to pass through. Mold venting is one application.

Watch