Mold Tooling

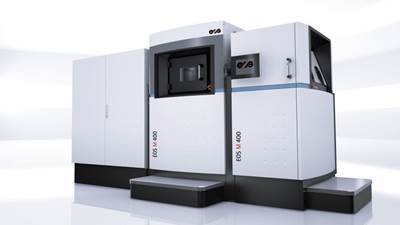

EOS in Two IMTS Pavilions with AM Advances

Applications include multi-part production and an automated system for mold tooling. The company’s North American User Day also returns to IMTS.

Read MoreCollaborate and Educate

Baker Industries pushes AM development and educates customers at a new collaboration center for emerging injection mold technologies.

Read MoreTopological Analysis Predicts That a Hollow Mold Insert Will Succeed

Mathematical analysis performed for a mold shop reveals that almost all of the metal in a mold core insert was unnecessary to that tool’s function.

Read MoreMichigan Plastics Molder Experiments with Mold Inserts that are Hollow

PTI Engineered Plastics sees open possibilities in an alternate method of making mold tooling through AM.

Read MoreR&D Project Demonstrates Metal AM for Mold Tooling Makers

A 3D printing bureau and mold tooling maker installed a direct-metal AM machine as part of a grant-funded R&D project. The parts it is producing will serve as illustrations of additive’s capabilities for other moldmakers.

Read MoreExpanding Horizons with Rapid Tooling

Investing in 3D printing for rapid tooling brought product development time from months down to weeks for this moldmaker.

Read MoreCase Studies of Multi-Material Manufacturing

Tools for injection molding, die casting and powder compaction all illustrate the potential to achieve greater part performance and manufacturing efficiency by blending workpiece materials through AM.

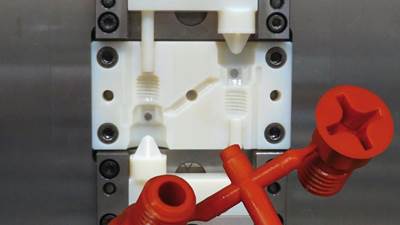

Read More3D Printing Impacts Production Mold Design

3D-printed cavities and cores serve as a testing ground to quickly prove out production mold design options.

Read MoreAgility Through 3D Printing

Additive manufacturing capability has helped this shop stay flexible, in both the prototyping and moldmaking parts of its business.

Read MoreShaking Off the Support System

Ultrasonics can remove mold support from the surfaces of an additively manufactured part and reduce cleaning time.

Read More