Rebuild, Don't Replace

If you could rebuild a damaged or worn-out mold insert instead of replacing it with a new one, wouldn’t you?

Repairing damaged mold inserts is a growth area for additive manufacturing, particularly for direct metal laser sintering (DMLS). Rather than replacing damaged tools, DMLS can be used to quickly repair only the damaged areas, resulting in simplified repair, decreased downtime, longer operating life and reduced costs associated with maintenance and repair.

Conventional repair processes can require multiple steps and be time-consuming. Welding, for example, requires cutting out the broken or worn area, fixing a new block of steel, performing the welding and completely re-machining the insert. It also can involve additional steps such as machining, polishing, testing, etc., and it has limitations, such as the durability of the repair.

The need for faster, more economical ways to repair mold inserts has opened the door for DMLS. Two companies, Ecoparts and Innomia, have walked through that door and now offer customers the speed and cost advantages of DMLS tool repair. Innomia provides plastic and metal part design and development using reverse engineering, 3D scanning and additive manufacturing. Ecoparts is an EOS service provider that produces prototypes, short runs and tool inserts, as well as hot runner water-cooled gate inserts, for the mold and die and mechanical engineering industries.

“In general, laser welding is very good for repairing damaged corners, edges or thin layer defects when there is no need to add to the material’s volume,” says Lubos Rozkosny, managing director of Innomia (innomia.cz). “When it’s more suitable to add material volume to repair the damaged area, DMLS is very efficient. It can bring material back to the exact 3D geometry specified by the part’s 3D model. This is not possible using laser welding because the process is manually controlled. DMLS can because the laser beam is computer-controlled by the CAD file.”

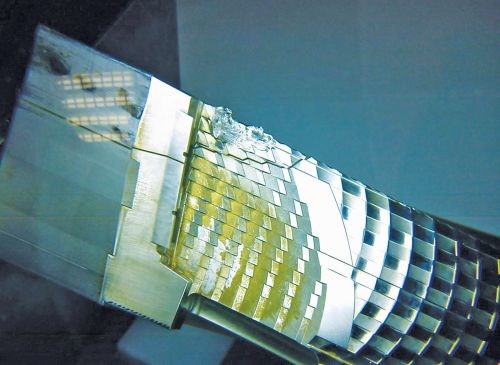

In general, DMLS works by melting very fine layers of metal powders from the bottom up until the build is complete, creating a single homogenous part made of steel. To start, a thin layer of pure tool steel powder material is applied to the building platform. A powerful laser beam then fuses the powder at exactly the points defined by the computer-generated component design data. The platform is then lowered and another layer of powder is applied. Once again the material is fused so as to bond with the layer below at the predefined points.

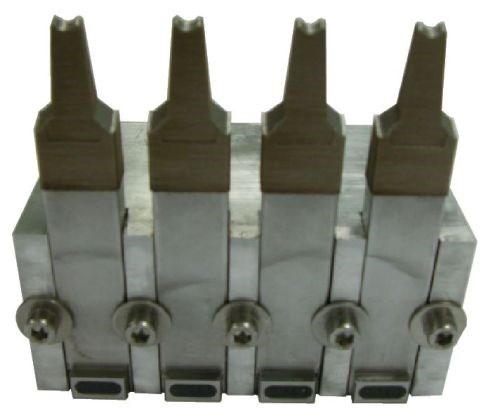

When it comes to insert repair, however, DMLS has a different approach. “You don’t repair the inserts by welding together two broken or damaged parts,” explains Daniel Kundig, owner and managing director of Ecoparts (ecoparts.ch). “Instead, you completely rebuild the damaged area of the insert. This ensures a homogeneous microstructure in the parts, without having visible weld lines on the repaired insert.” After the DMLS process, inserts can be post-processed (for example, via milling or polishing), as required. The insert’s functionality is saved and reestablished.

DMLS melts material back onto the damaged area, and metals used in DMLS offer very good mechanical properties, Mr. Rozkosny says. For example, MS11.2709 maraging steel offers a hardness ranging to 54 HRc. (Heat treatment can be used to adjust the hardness between 34 and 54 HRc.) In addition, different tool steels can be combined, limited only by the size of the sintered surface and weldability of the materials. DMLS also runs in an airtight chamber under an inert nitrogen atmosphere, ensuring a very good metal structure. Finally, it offers short lead times and suitable quality, Mr. Rozkosny says.

Innomia and Ecoparts do see a few limitations to using DMLS, however: (1) current chamber size (250 x 250 x 325 mm) limits the size of parts that can be repaired; (2) surface finish is rough (about 10 Ra), requiring conventional finishing processes; (3) the layer-by-layer process demands a flat surface; and (4) only one material (1.2709) currently is approved for tooling. However, the high accuracy and surface quality after finishing that DMLS offers make it an ideal platform for tooling applications, including tool repair. Also, inserts repaired using DMLS are proving to prolong tool life.

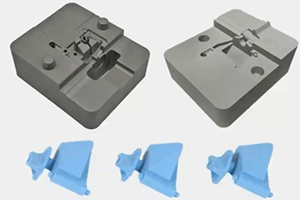

Mr. Kundig adds that part complexity also is not a cost driver with DMLS. “Simple or complex structure, free-form shape or conformal cooling, the industrial 3D printer just manufactures the part,” he says.

Rebuild and Repair

Both Innomia and Ecoparts have seen growing demand for the use of DMLS to repair mold inserts, as it simplifies and speeds the repair process. Instead of replacing inserts, both companies remove only the damaged material for their customers. In most cases, this alternative to completely remanufacturing an insert saves weeks in production time.

According to Mr. Rozkosny, Innomia initially ventured into metal additive manufacturing with rapid prototyping of automotive metal components but then moved to injection mold applications, including rapid tooling and conformal cooling. Since then, customers have come to trust the quality of DMLS parts in production tooling, he says, so demand for fast tool repairs grew very quickly.

When it comes to tool repair, Innomia uses not only DMLS, but also 3D scanning and reverse engineering. This allows the company to repair damaged tools, even when 2D or 3D documentation is unavailable. For one particular repair on a broken injection mold insert, there were no existing 3D data or drawings, and limited parts in stock.

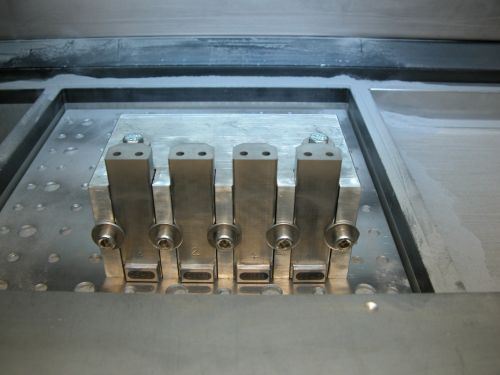

“The insert was removed from the tool and delivered to us,” Mr. Rozkosny explains. “First we scanned the insert geometry and redesigned the complete 3D model. Then we cut or milled off the damaged area because we needed a flat surface to start the rebuilding process. The insert was then placed into the EOSINT M 270 system and positioned, and the missing material was laser-sintered on the cut surface. Next, the surface was finished and the insert was mounted back into the mold.”

The job, from insert removal to production restart, was completed in three shifts, and the repaired insert has been in use for two and a half years now, demonstrating the repair’s quality and durability, he says.

Related Content

Video: Mold Base for Product Development With 3D Printed Molds

Alba Enterprises created a mold base to match the needs and pacing of product iteration using mold tooling made via additive manufacturing

Read MoreNicolet Plastics Succeeds Using Mantle's Hybrid Metal 3D Printing Method for Mold Tooling

A recent webinar explores Nicolet Plastics’ success using Trueshape Technology, Mantle’s approach to print injection mold tooling. The current challenges this technology addresses and alleviates in additive manufacturing confirms this method is effectively reducing lead times and cost constraints, while producing better inserts.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreIn Casting and Molding, AM Simplifies Conventional Manufacturing

In new ways, additive processes are streamlining and enabling metal casting and plastic injection molding.

Read MoreRead Next

Cracking the Code to Growth in AM

It takes more than machines on the shop floor to push additive manufacturing to the next level. According to one manufacturer, it takes customer service, education and training, too.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More