Shaking Off the Support System

Ultrasonics can remove mold support from the surfaces of an additively manufactured part and reduce cleaning time.

Additive technology has taken manufacturing to a new level but it’s not without its challenges, two of those challenges being supporting parts as they are built and meeting postprocessing requirements. Early on, additive manufacturing was limited in the parts it could produce. “It couldn’t print a part with overhanging shelves, ledges or cavities because there was no way to support them while they printed,” says Frank Pedeflous, president of Omegasonics. That problem was solved with mold support.

Mold support enables 3D printers to achieve the elaborate shapes that in the past could be made only by casting or machining processes. Pedeflous explains, “The mold support works as a reverse image of the finished part—a placeholder, so to speak. This soluble support material is technically classified as a synthetic thermoplastic polymer resin. It is deposited from a second nozzle in the same print head used to print the actual part.”

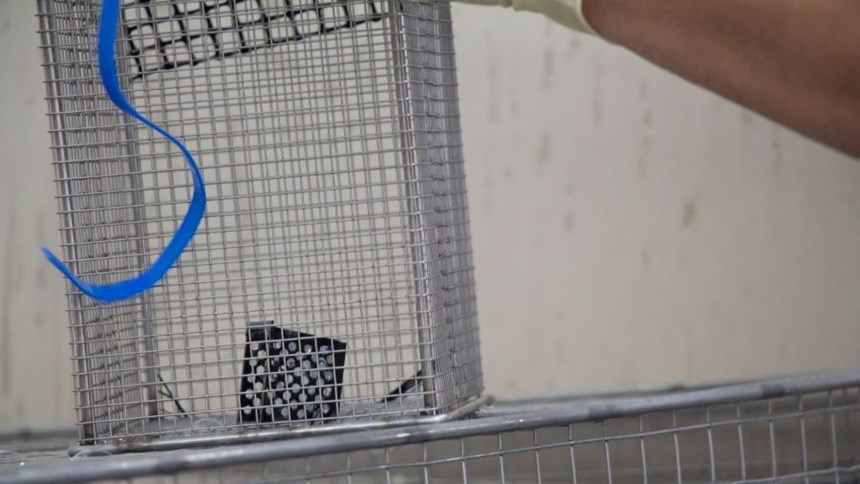

Such support enables intricate, delicate objects to be printed. However, after a part is created and hardened, any mold support or loose material and edges must be removed. This cleaning and finishing stage is where ultrasonic cleaning can help. According to Pedeflous, ultrasonics are a reliable, safe and effective way to remove mold support from the surfaces of an additively manufactured part and to reduce cleaning time compared to manual methods.

Parts could be cleaned with a heated circulating-bath washer or hot-water spraying system, but both of these methods require cleaning cycles that are five to eight times longer than ultrasonic cleaning, Pedeflous says. And high water pressure could potentially damage parts. Also, the larger the object, the larger the requirement for additional process time, cleaning detergent and agitation to dissolve the support material. Manual, hand-cleaning is another option, but this can be very time-consuming, and it may be near impossible to completely remove debris on more complex or intricate structures. Aggressive scrubbing or the use of hand picks can also cause damage to the parts.

“With ultrasonic cleaning, finished parts can be dropped into the ultrasonic cleaning tank, and the support material is gently and completely removed. Parts come out clean of any debris, without requiring manual labor,” Pedeflous says.

He explains that to properly and efficiently clean 3D-printed parts with ultrasonics, parts simply need to be fully submerged into a solution. Since mold support material is water-soluble, a high-alkaline concentrate mixed with water at a temperature ranging from 150°F to 175°F (depending upon the material being cleaned) is the only other requirement.

Parts are not damaged in ultrasonic cleaning, because this process uses cavitation rather than pressurized spray to clean. Cavitation causes vacuum-pressure bubbles in the water to implode when they come in contact with a hard surface, thus removing dirt particles. These small bubbles are able to get into and clean the resin from even the most seemingly inaccessible cracks, crevices, blind holes and passageways.

It might be time to consider ultrasonic cleaning as an integral part of your additive manufacturing process. As described here, it can help remove most mold support quickly and completely, reducing the time needed to manufacture the part and have it ready for the next step in the assembly process, or ready to ship to the customer.

Related Content

Airless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read More6 Trends in Additive Manufacturing Technology at IMTS 2024

3D printers are getting bigger, faster and smarter. But don’t overlook the other equipment that the AM workflow requires, nor the value of finding the right supplier.

Read MoreQ&A With Align EVP: Why the Invisalign Manufacturer Acquired Cubicure, and the Future of Personalized Orthodontics

Align Technology produces nearly 1 million unique aligner parts per day. Its acquisition of technology supplier Cubicure in January supports demand for 3D printed tooling and direct printed orthodontic devices at mass scale.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More