Michigan Plastics Molder Experiments with Mold Inserts that are Hollow

PTI Engineered Plastics sees open possibilities in an alternate method of making mold tooling through AM.

What is the most effective way to apply additive manufacturing? Manufacturers are still discovering the answers to this question, because we are still at such an early stage in the advance of AM that the complete scope of its use is not yet clear. Part of the challenge is this: Today’s manufacturing processes work quite well for today’s parts. The best applications of additive often involve parts designed for additive—parts that can’t be made in any other way. In short, part of what has held us back so far is the limit of our imagination. We haven’t yet thought of all the parts that can take full advantage of what additive can do.

One company that can testify to this is PTI Engineered Plastics of Macomb, Michigan. This maker of injection-molded plastic parts is nothing if not imaginative—it applies in-house mold engineering and mold machining capabilities to overcome sophisticated injection molding challenges for automakers and medical device makers (among others). And yet, PTI only recently came to the realization that it was not being innovative enough in its exploration of the promise of an additive process for making injection mold tooling.

For more than a year, the company experimented with injection mold inserts made through additive manufacturing to include conformal cooling. That is, on a powder-bed metal additive manufacturing machine, mold inserts were generated to include curving internal cooling channels that replace the typical drilled holes. The result was improved cooling of the mold, because the channels made this way could follow the mold’s contoured surface. In general, though, the result was not enough cooling improvement to justify the cost of making inserts this way in place of machining them.

And yet, Scott Kraemer, PTI’s directing manager of new technology, says the problem with this comparison was that even conformal cooling is still beholden to established methods and assumptions for making molds.

He couldn’t see this at the time, he says. But as he eventually came to realize, using channels to convey water for cooling is part of the way molds are “supposed” to function. He wondered, did those channels even have to be there?

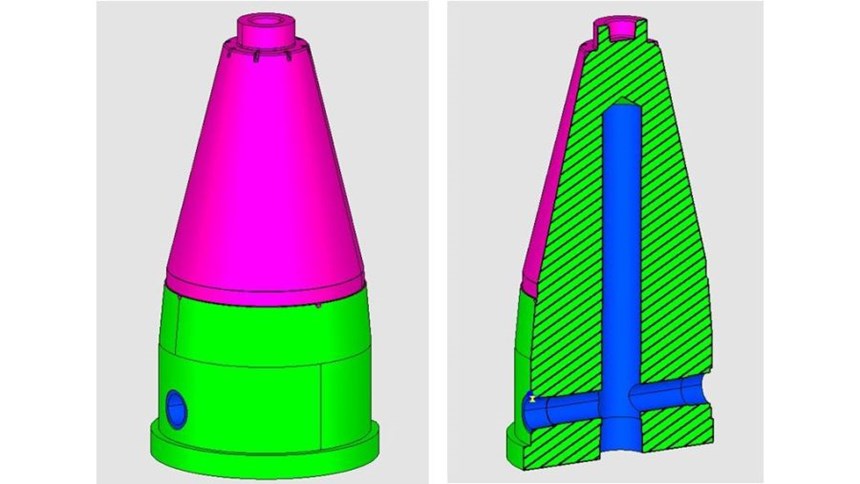

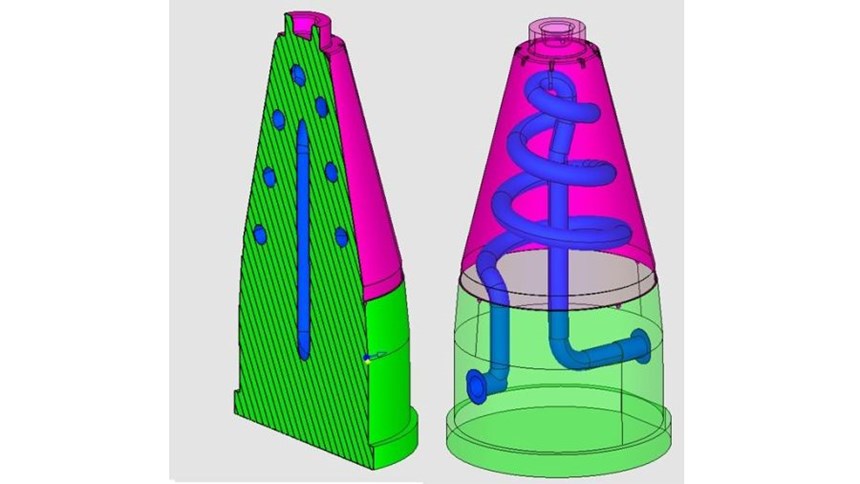

Here is an alternate idea: Instead of employing channels, the mold insert could be hollow. The cooling medium could fill its inner volume. Just as additive manufacturing could grow an insert with curving internal channels, it could also grow an insert with open internal space. Indeed, growing “nothing” as the internal geometry would be preferable to growing channels, because additive manufacturing could produce the hollow form more quickly and cheaply than producing the more nearly solid part.

To be sure, the notion of a hollow mold insert is strange. It was strange to Kraemer when the idea first occurred to him. A hollow insert is lightweight. That seems wrong. Molds need to withstand the high pressure of injection molding, so tooling has to be heavy and substantial—or so it was previously thought.

PTI recently ran an important test. For an injection mold core about 7 inches tall related to a medical device, mathematical analysis suggested that a thin-walled hollow version of this core could provide the needed strength. Trusting that analysis, PTI 3D printed this hollow core in tool steel so that it could be tested for making production parts.

During the testing, Kraemer says the molding machine operator was attentive to say the least. He was ready for the lightweight insert to crack under the pressure of molding. But the tool did not crack. It held and it worked—and in fact it worked well. Even in spite of some problems that were discovered in the course of this initial test, the hollow mold tool worked effectively enough to demonstrate that this idea is not only sound, but promising.

A basic point about injection molding is that much of the cycle time to make the plastic part is cooling time. Therefore, bringing improved cooling to the process directly achieves higher productivity. In the test run with the hollow mold, this new tool’s cooling effectiveness permitted a molding cycle time of 41.5 seconds versus the 46.5 seconds that had previously been accepted for this part. That level of improvement is comparable to what an identical core with conformal cooling might have achieved, even though that core, which is more solid, would have required much more metal and time to produce in an additive process. And Kraemer says some obvious potential improvements revealed by the first test are likely to decrease the molding cycle time still further.

It’s early, he says. It is too soon to draw conclusions. The company has tested just this one core. To learn more, it needs to test many more hollow inserts for many different shapes and sizes of molded parts. However, when that initial trial run ended for the first hollow mold tool, Kraemer says he was aware that he had witnessed a potentially important new option for making mold tooling, and the way that PTI might be making many more mold inserts in the future.

CO2 Cooling

For this first experimental insert, there was also another important detail of the process. Hollowness was half the story. The other half was the cooling medium. In the trial run, the hollow core was filled not with the usual mold cooling fluid, water, but instead was filled with liquid carbon dioxide.

Experimentation with CO2 is actually what led PTI to the leap of making the insert hollow, Kraemer says. For a long time—months if not an entire year—the company pursued additive manufacturing and CO2 cooling without realizing that these might be related areas of exploration.

A portable, programmable CO2 delivery system is provided by Linde, a company known for industrial gasses. This system was not developed for molding, but in PTI’s vicinity, a local Linde employee who once worked in plastics made the connection to the cooling needs of this industry. That contact reached out to PTI, which saw the same promise and began to test the system.

PTI’s evaluation of this cooling revealed that it was effective for cooling small and troublesome details of a mold. However, anything beyond spot cooling seemed impossible, at least initially, because the cooling effect comes from phase change rather than fluid flow. The liquid CO2 becomes gas when it hits atmospheric pressure, absorbing heat at the moment of this change. Sending liquid CO2 through the long cooling channels of a mold would therefore accomplish little. To cool an entire mold surface, Kraemer says there would have to be some way to expose the entire inner volume of the mold tool to a blast of CO2 all at once. That was the line of thinking that led him to the insight about replacing an insert’s channels with an entirely open inner volume.

Now, the hollow mold concept has renewed PTI’s interest in additive manufacturing. Using additive to realize conformal cooling was proving challenging in multiple ways. First, the powder metal cost and the long build times tend to make conformally cooled inserts expensive. Also, Kraemer says adjacent channels curving in parallel along the mold surface produce bands of hot and cold that sometimes warp the part.

He adds, “And how do you keep all those curving internal channels clean?” Free, that is, of both contaminants and rust. For conformally cooled inserts, the company has not found an easy and effective way to do this.

Hollow molds address all these problems, he says. Because they are hollow, the material cost is less. Build time is also less—between one-third and one-half the additive build time of an identical tool featuring internal channels. The cooling effect is more uniform across the mold surface. And while there are still entry and exit channels for the cooling fluid that need to be kept unobstructed, these are straight and easy to clean.

In the trial run of the first hollow core, CO2 as the cooling fluid arguably worked too well, Kraemer says. The polymer being molded demanded a minimum temperature of 140°F. Pumping liquid CO2 into the core threatened to cool the surface lower than this. PTI therefore held back on the CO2 during this test, allowing the mold to become hot for a span of time before the cooling was introduced to the cycle. But even at this, rapid cooling from the high temperature resulted in the injection molding process’s material runners sticking to the sides of the plastic part. PTI was therefore limited to cooling only fast enough to achieve a 5-second cycle-time improvement. The potential for much faster cooling will be available once the company can engineer a solution to the runner problem.

Another difficulty discovered in the initial test: The cooling effect was most concentrated at the tip of the core, while the very bottom of the core insert remained too hot. Kraemer says the problem here might have been that the inlet did not deliver CO2 to the optimal depth. Or, the problem might have been that CO2 was not the appropriate cooling medium for this core after all. This unusual cooling method did lead PTI to the hollow tool idea, but it is not essential for using a hollow tool. It might be that filling the hollow space of this insert with water actually represents the better way to cool this part.

The Significance of Seconds

Again, it’s still early. Additional testing will further refine the hollow-mold idea. And adoption will improve the cost-effectiveness, because PTI will get better prices for powder metal once it begins to buy more of it.

Kraemer says one objection he has heard to the potential promise of hollow mold inserts is that the resulting level of savings in molding cycle time is not important. Those savings are meaningful only on high-volume molds, but for molds making shorter runs, the value of a few seconds per plastic part is not significant.

He says the flaw in this objection is that it misses the full scope of what he thinks PTI will ultimately be able to offer to its customers. He does not see this improved approach to mold cooling as being just a niche solution. Instead, he sees this as being potentially applicable to practically any molding job. If future testing of this idea goes as well as the first test did, then he can envision finding the optimal hollow volume of each mold insert becoming a standard part of mold engineering for each job. Along with this, he can see both water and CO2 being considered as the cooling fluid choice for any given hollow tool.

It is true, he says—a few seconds per cycle do not mean much for just a low-volume job.

But a few seconds per cycle will make a dramatic difference for PTI’s costs and capacity once practically every job is realizing this benefit, because practically every job is running with a radically different type of mold.

Related Content

3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MorePreassembled Turbojet Engine, 3D Printed in One Build: The Cool Parts Show #75

Turbojet engines typically consist of hundreds or thousands of parts, but this engine — 2023 winner of The Cool Parts Showcase for Best Proof of Concept — was 3D printed as just two pieces, with the monolithic rotor embedded inside the stationary engine shell.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More