R&D Project Demonstrates Metal AM for Mold Tooling Makers

A 3D printing bureau and mold tooling maker installed a direct-metal AM machine as part of a grant-funded R&D project. The parts it is producing will serve as illustrations of additive’s capabilities for other moldmakers.

Companies making injection molds and other plastics mold tooling in the Dayton, Ohio, area will soon have a nearby resource for learning what additive manufacturing (AM) can bring to this toolmaking. As part of a project funded by a grant from the Ohio Development Services Agency, Dayton 3D printing firm Bastech has installed a ProX 200 Direct Metal Printing (DMP) machine from 3D Systems, and is developing an injection mold tooling case study using this machine that will help it convey the benefits and best practices of growing mold tooling through additive manufacturing to mold shops throughout the area.

Bastech itself is no stranger to toolmaking. The 3D printing service bureau and equipment reseller has a history of producing not just investment casting patterns but also short-run rapid tooling, using both traditional machining and nontraditional processes. In addition to its additive lab, Bastech has a full machine shop where it cuts metal tools from stock and finishes those that have been forged off-site. Now, the project aimed at creating production injection mold tooling on its new metal additive manufacturing machine will enable the company to produce complex mold cores and cavities through AM, while serving as an example for fellow toolmakers.

The ProX 200 was installed in Bastech’s additive lab in January 2016. This model was chosen in part because Bastech is an authorized reseller of 3D Systems equipment and has an established relationship with the builder. The machine also met the project requirements in terms of supported materials, level of control and print quality. Company founder Ben Staub and his firm’s engineering manager were both trained on the system. Staub also designed the sample products to be used in the R&D project, sleeves with detachable caps to hold a beverage can or bottle that can function as a giveaway during the project’s promotion. The case study will focus on additively manufacturing injection mold cores and cavities to produce the sleeves.

In the first phase of the project, the company built the core for a can sleeve mold from stainless steel 316 in the ProX machine. Staub wanted to choose a design where additive manufacturing could provide added value. For the mold core, this value comes in the form of complex conformal cooling channels.

The core that was developed includes two sets of channels spiraling inside its cylindrical body—one carrying coolant from top to bottom, and the other from bottom to top. This pattern helps to ensure more even cooling distribution throughout the entire length of the core; if coolant flowed in only one direction, it would heat too much by the time it reached the other end. The channels were designed with a clover-shaped geometry to increase the surface area and add turbulence to the fluid, further improving the cooling of the mold.

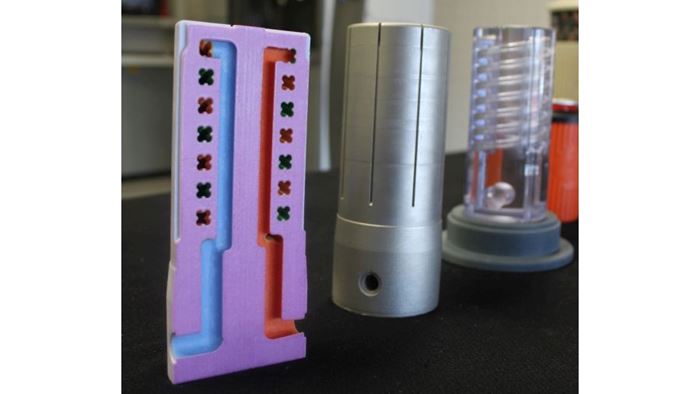

Because the goal of the project is to educate, not just produce, Bastech has leveraged its polymer 3D printing capability to create visual aids that show off the design features of this test part. In the first photo above, a prototype of the metal core is flanked by a full-sized clear plastic model that shows the paths of the conformal cooling channels. On the other side a color-coded cross-section model made on the company’s 3D Systems ColorJet 3D printer shows the clover shape and layout of the channels. The blue coloring represents the cool incoming coolant, while the red indicates hot, outgoing fluid.

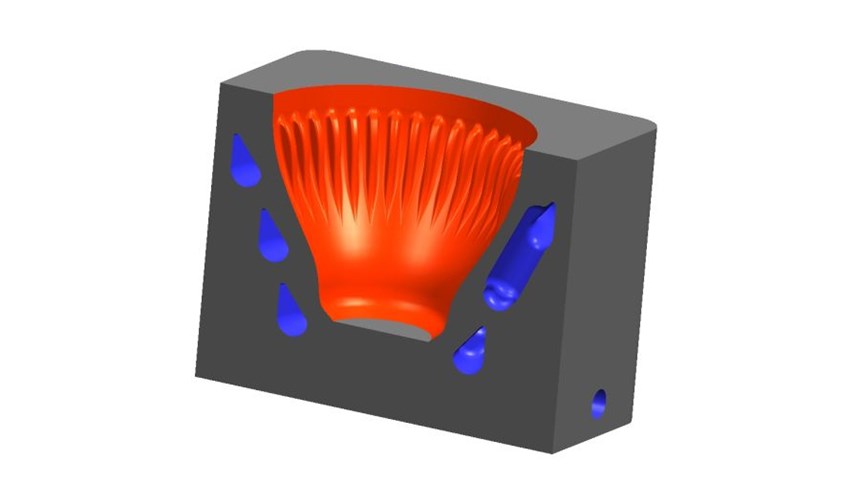

The core is the critical AM part for this particular mold, as the cavity for the can sleeve is machined. However, the next phase of the project will build both the core and cavity of the top for the bottle sleeve in the DMP machine. These two mold components will be built from maraging steel. Bastech developed a new cooling concept for the cavity of this mold using a teardrop-shaped channel geometry, shown in the second image. This geometry is easier to build than the clover shape, and can more closely match the contour of the part for even cooling distribution.

In addition to enabling the production of these complex mold components, Staub notes that the DMP system is also increasing the shop’s capacity. The company’s growth has been challenged by the difficulty in finding skilled toolmakers and CNC operators, and the need for existing employees to spend time setting up jobs and moving parts between machines. A typical metal mold component made in Bastech’s machine shop requires a series of steps including milling, designing and cutting electrodes, and EDM work, which means multiple setups and a high level of operator involvement. The additive machine, on the other hand, can run 24/7 and produce high-quality, complex tooling largely unattended. In the few months since installing the AM machine, Bastech has already seen how it can open up employee time for other tasks.

As a result of this project Staub hopes to demonstrate to other moldmakers that direct metal additive manufacturing is a viable process for building mold tooling, whether they are considering it as an outsourced option or an in-house capability. In addition to telling customers about its new capability during regular business, Bastech is displaying its test parts and talking about the project at local and national trade shows and conferences throughout 2016. Case studies and other documentation are expected to be published in 2017.

The project also has implications for future AM machines. As it continues to use the technology, Bastech will share data about its work with 3D Systems and eventually serve as a beta tester to help the builder prove out new features. Bastech is already exploring other applications for the ProX 200. One of the earliest production jobs it is running on this machine is end-use parts for an aerospace customer; Staub sees more mold tooling and work like this for the machine down the road.

Related Content

Video: Hybrid Manufacturing Without Melting: Hermle’s Metal Powder Application (MPA) Process

The Metal Powder Application (MPA) process uses cold spray to apply metal to an existing workpiece. Because the material deforms rather than melts, MPA opens new possibilities for functional grading and other multimaterial applications.

Read MoreCombining Metal and Polymer for Better 3D Printed Tools

Applications prone to wear call for more durable tooling than 3D printed polymer alone, but full metal is not always necessary.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read MoreComplete Speaker Lineup Announced for the 3D Printing Workshop at NPE2024: The Plastics Show

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More

.jpg;width=70;height=70;mode=crop)