Topological Analysis Predicts That a Hollow Mold Insert Will Succeed

Mathematical analysis performed for a mold shop reveals that almost all of the metal in a mold core insert was unnecessary to that tool’s function.

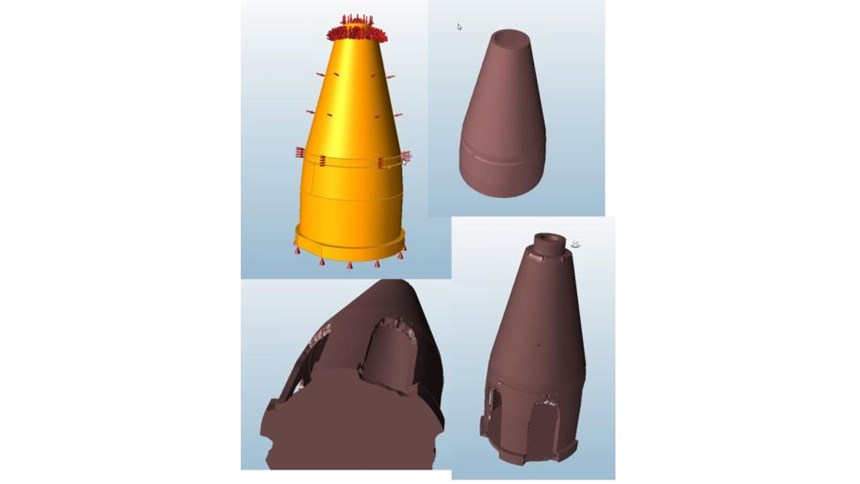

To develop an injection mold insert that used additive manufacturing to realize internal hollow space in place of conformal cooling channels, plastics manufacturer PTI Engineered Plastics employed a design tool that is not typical of moldmaking. Because injection molding involves high pressure that the mold has to withstand, PTI needed topological analysis software to determine just how hollow the hollow insert could be.

The software used was Inspire, developed by Altair. PTI does not own a seat of this software, though it might obtain this or another analysis tool as it continues to experiment with the promise of of hollow tooling. Instead, company directing manager of new technology Scott Kraemer provided an Altair consultant with the mold insert’s existing CAD geometry, along with the pattern of forces predicted by mold flow software. He asked the consultant to redesign this insert (the core of this particular mold) to achieve the largest permissible internal hollow volume that would still enable the tool to withstand the anticipated pressures.

Knowing something about moldmaking, the consultant expressed puzzlement at this request. Kraemer reassured him that, yes, a hollow mold insert was what he wanted.

He expected the mathematical analysis to reveal the need for some array of internal supports, he says. That is, he expected Inspire to predict the need for something like supporting internal columns or an internal lattice. The actual result was a surprise. Assuming the material was maraging steel, the analysis said that a wall thickness of 3.5 mm would be enough to support the load. No internal supports were needed.

The result was actually unnerving for reasons that went beyond the walls’ thinness. The current core insert the company had been using for this job was a solid steel part, just like every other injection mold core and cavity throughout the shop. Indeed, essentially every core and cavity used for full production throughout the plastics industry is solid steel. Kraemer therefore wonders: Are molds really that much heavier than they need to be? Is there really that much unnecessary metal being used for tooling?

In the core model, he increased the wall thickness to 4.0 mm just to add a safety factor, but did not add internal supports of any kind. Topological analysis might reveal that other insert designs in the future do need these supports. But in the case of the very first test of the hollow-mold idea, the analysis revealed that the mold core used for this testing could be truly and entirely hollow.

Related Content

-

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

-

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

-

Flexible Bellows Made Through Metal 3D Printing: The Cool Parts Show #64

Can laser powder bed fusion create metal parts with controlled flexibility? We explore an example in this episode of The Cool Parts Show.