Metal

Arcam Acquires Medical Manufacturer DiSanto Technology

Part of what the additive machine maker gains by acquiring this part producer is CNC machining capacity and expertise. The move follows the acquisition of a Canadian metal powder company.

Read MoreVideo: Additive Manufacturing of Metal Matrix Composites for High-Hardness Parts

Combining a ductile phase with a hard phase in a single build generates hard ferrous parts without cracking. Possibilities now include additive manufacturing of cutting tools, dies, bearings and downhole hardware.

WatchVideo: Racing Engine Oil Pump Gear Produced through Additive Manufacturing

High complexity and low quantity made this critical part a candidate for 3D printing.

WatchRebuild, Don't Replace

If you could rebuild a damaged or worn-out mold insert instead of replacing it with a new one, wouldn’t you?

Read MoreVideo: Additive Manufacturing at Linear Mold

The company uses 3D printing to create conformal-cooling mold inserts in addition to production parts.

WatchVideo: World’s Largest Additive Metal Manufacturing Plant

GE Aviation facility in Italy will have capacity for 60 machines making metal production parts through additive manufacturing.

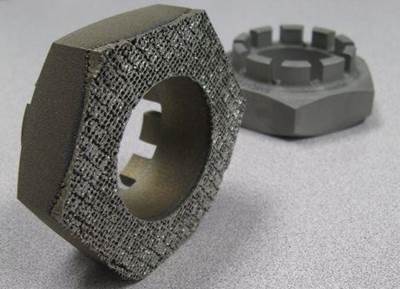

WatchHow Do You Make a Howitzer Less Heavy?

Large nuts that used to be solid metal are now grown with a honeycomb structure on the inside for valuable weight savings.

Read MoreCracking the Code to Growth in AM

It takes more than machines on the shop floor to push additive manufacturing to the next level. According to one manufacturer, it takes customer service, education and training, too.

Read MoreLearning Curve

A manufacturer that has succeeded for three generations expects additive manufacturing to be part of the reason why it will succeed in the fourth. One year into its investment in the technology, here is the company’s experience so far.

Read MoreVideo: 3D Printing with Carbon Fiber

Make parts as strong as metal on a desktop machine, the company says.

Watch