Metal

Will Additive Manufacturing Play a Major Role in Aircraft Production?

One answer: It already does. Lockheed Martin discusses the challenges and promise of producing parts through 3D printing.

Read MoreWinner Named in First-Ever International Additive Manufacturing Award

Hybrid Manufacturing Technologies Ltd. will receive the inaugural International Additive Manufacturing Award (IAMA) for its innovative methodology that enables metal deposition (via laser cladding) to be integrated on a multi-axis CNC machine.

Read MoreInterest in Additive Manufacturing Enters Phase Two

How long until we see acceptance of additive manufacturing for full-scale production of a wide variety of metal parts? Three to five years, says this AM researcher.

Read MoreAdditive’s Idiosyncrasies

Additive manufacturing is not as easy as just hitting “print.” Like any manufacturing process, it demands attention to considerations that are characteristic of this process alone.

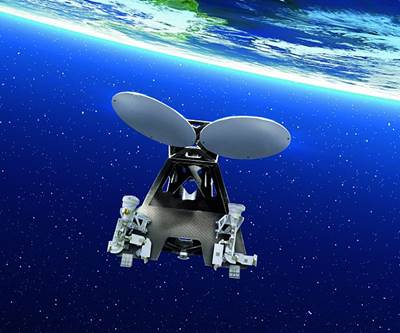

Read MoreAdditive Manufacturing of Brackets Saves 1 Kilogram per Satellite

Because of complexity, material and quantity, spacecraft and satellite components are good candidates for additive production.

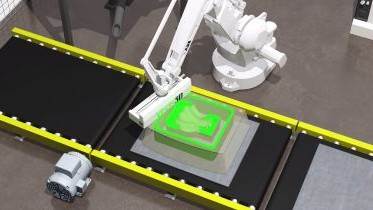

Read MoreVideo: Additive Manufacturing Robot for Foundry Molds

In addition to making either metal or plastic parts, one other production application of additive manufacturing is building in sand to create molds for casting without any need for a pattern.

WatchRenishaw to Introduce Additive Manufacturing System Aimed at Production

The first machine developed in-house by the company features a high-power laser and automation for industrial production via additive manufacturing.

Read MoreTwo Heads Better Than One in Hybrid Additive/Subtractive Machine

New Mazak Integrex capable of additive manufacturing includes heads for both high speed and high precision metal deposition. “Natural extension of multitasking,” the company says.

Read MoreMultiplying Options

Additive manufacturing’s greatest impact for this company is the versatility that has allowed it to offer different solutions than other manufacturers.

Read MoreNothing But Design Intent

The way to save cost through additive manufacturing is not only to use it to eliminate unnecessary material, but also to apply it within a process that avoids unnecessary effort and interpretation by keeping all manufacturing information within the digital realm. Lockheed Martin is pursuing this ideal.

Read More