Metal

Video: Will AM Subtract from Machining?

Don’t underestimate machining, which has capabilities additive can’t compete with. AM will have its greatest impact on parts that are designed specifically for this process.

WatchLowering Barriers, Part Two: An Update on Renishaw’s Solutions Centers

Currently in progress, Renishaw’s Solutions Center Network is intended to help manufacturers learn to use additive manufacturing effectively.

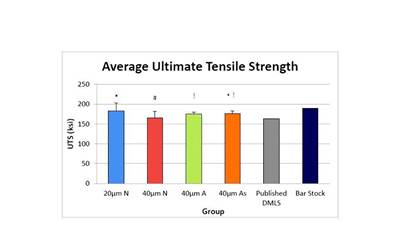

Read MoreComparing Mechanical Properties of DMLS Vs. Barstock Parts

A study conducted by researchers from Lawrence Technology University looked at whether DMLS parts can offer the tensile and yield strength of those machined from barstock.

Read MoreManage AM Expectations with Simulation

Move additive manufacturing away from empirically driven development with simulation.

Read MoreDMRC Research Examines Properties of SLM Components

What will it take to bring metal 3D printing up to the level of true production manufacturing?

Read MoreSelective Laser Melting in Action

Four recent projects take on selective laser melting technology to improve part design, process speed, safety and flexibility.

Read MoreNew Research Advancing Additive Manufacturing Viability

New research shows that 3D-printed parts are similar to barstock and have high manufacturing repeatability.

Read MoreSoftware Contributes to Faster Metal AM Production

Updates to EOSystem DMLS software and systems enable users to set up jobs faster and better monitor parameters during a build.

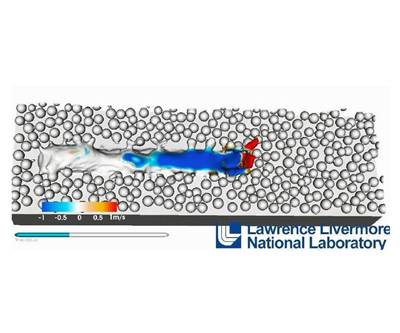

Read MoreThe Value of Metal and Powder Simulation

Two videos from Lawrence Livermore National Laboratories show how SLM works at the powder level.

WatchVideo: The Additive Nozzle’s Origin Story

The LEAP engine fuel nozzle is likely additive’s greatest success in part production so far, but it wasn’t always clear that the nozzle could be made this way. This video from GE Aviation tells the story.

Watch