Metal

Desktop Metal Releases Corrosion-Resistant Stainless Steel

Desktop Metal’s 316L stainless steel, developed for the Studio System metal 3D printing system, offers corrosion resistance at extreme temperatures.

Read MoreExtrude Hone Thermal Energy Method Removes Metal AM Supports

Rapid 2019: Extrude Hone showcases a proprietary approach that uses thermal energy method (TEM) to address metal support structure removal.

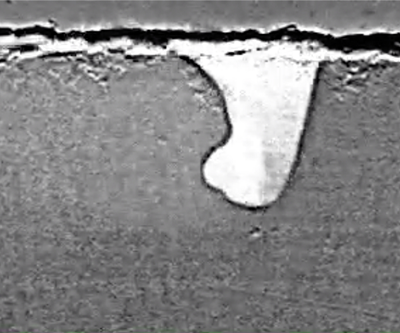

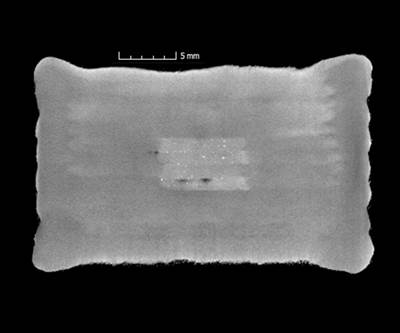

Read MoreCarnegie Mellon University and Argonne National Laboratory Seek to Understand Gas-Driven Micro Defects in Metal AM Parts

Better understanding of "keyhole" formations resulting from boiling metal will lead to better control over laser powder-bed fusion.

Read MoreThree Cool Uses for Directed Energy Deposition

Most machining professionals don’t like to admit that they ever make mistakes, but every now and then wouldn’t it be nice to have an “eraser” to go back and repair a gouge or fix a nicked edge? Or maybe you took off a bit too much material on that last machining pass and you’d like to add it back? Well, directed energy deposition (DED) enables you to do that and more.

Read MoreInert's Postprocessing Enclosure Limits Contamination

Rapid 2019: Inert’s PowderShield enclosure can safely postprocess metal 3D prints and maintain a strict argon gas atmosphere of less than 1 ppm O2 and H2O during the de-powdering process.

Read MoreHow a Solid-State Process Stood Firm Until Additive’s Moment

Early on, this company saw the promise of friction stir welding for building forms in layers. Few understood at the time. They understand now, in part because this process offers benefits such as blended materials and freedom from stress that other metal AM approaches can’t match.

WatchDMG MORI SLM Machine Offers Focal Diameter of 35 Microns

Rapid 2019: The Lasertec 12 SLM is said to offer improved accuracy for powder-bed fusion.

Read MoreDigital Metal Achieves UL Certification

Digital Metal has been authorized to apply the Underwriters Laboratories (UL) mark to its DM P2500 metal binder jetting system, the first such system to receive the UL certification.

Read MoreGrinding Improves Surface Finish in 3D Printed Inconel, Study Shows

3D printed metal parts typically feature little stock remaining for finishing. Grinding is potentially an effective solution for meeting final tolerances. An abrasive technology provider investigates grinding as a complement to AM.

Read MoreInert Gas in Metal 3D Printing, Materials and Postprocessing

High-end metal additive manufacturing relies on the perfect gas composition to create products that meet the required material properties. But gas such as argon is also key to metal powder production, storage and postprocessing.

Read More

.JPG;maxWidth=400;quality=70)