Three Cool Uses for Directed Energy Deposition

Most machining professionals don’t like to admit that they ever make mistakes, but every now and then wouldn’t it be nice to have an “eraser” to go back and repair a gouge or fix a nicked edge? Or maybe you took off a bit too much material on that last machining pass and you’d like to add it back? Well, directed energy deposition (DED) enables you to do that and more.

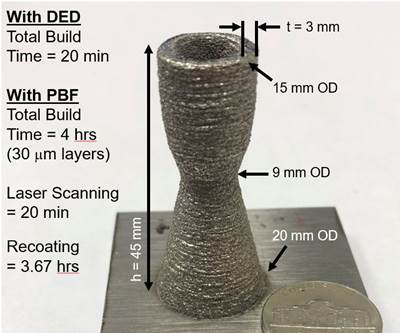

Directed Energy Deposition (DED) is basically laser cladding on steroids. Layer by layer, it additively manufactures a part by feeding powder or wire into a melt pool created by a laser, electron beam or plasma arc. It helps address the scalability issues with powder-bed fusion (PBF), and it can often build parts faster than PBF. The downside is part accuracy, but DED also enables better material utilization because the “blown powder” is fed directly into the melt pool versus spread in a layer, as with PBF. Material utilization is even better when using wire feed instead of powder feed for DED.

1. Fixing Mistakes

Because powder is blown/wire is fed into the melt pool, you do not have to build on a flat surface when using DED. This is where the idea of the “machinist’s eraser” comes from: If you accidently removed too much material from a part during machining, it is easy to add back with DED and start again. Granted, this will not work for every material, but DED is one of the more flexible forms of additive manufacturing (AM) in terms of materials that can be processed.

Aside from fixing mistakes, DED also provides an easy way to add ribs, bosses, flanges or connectors to an existing part. Rather than having to machine protrusions out of a larger piece of material, a conventional manufacturing process can be used to build the main body of the structure, and then DED can be used to add attachments to the outside (or inside) of the part with minimal scrap and material waste.

2. Repairs and Restoration

If we take the eraser metaphor to the extreme, then it is easy to see why DED is also good for repairs and restoration of worn components. No longer does an entire part need to be scrapped if a surface erodes or important features wear. Instead, DED can be used to add material and build the part back to its original geometry. In fact, in many cases in our lab, my colleagues have repaired parts for about $0.10 per dollar using DED—restoring the bearing surfaces on a $6,000 shaft for about $600 or relining surfaces on a $30,000 part for about $3,000.

3. Multi-Material Applications

Many DED systems also come with two or more powder hoppers, enabling you to run the system without interruption. Instead of filling both hoppers with identical powder, though, people are putting different alloys in each hopper and using DED to change the material composition during the build. This enables you to functionally grade the part, transitioning from say, a hard material at one end of the part to a corrosion-resistant material at the other end of a part without having to assemble a bunch of components with different material properties.

While we are only starting to understand the possibilities of functionally graded materials—let alone how to design, analyze and inspect them—one multi-material application that excites me most is “tagging” a part with a different material as the part is being built with DED. This enables new avenues for anti-counterfeiting, ensuring that the part you bought or are using is the real part and not a fake.

The example in the figure shows a small titanium part that is tagged with a second material in one of the layers as it is being built. You cannot see the difference with your eye, but if you x-ray the part with a hand-held scanner or in a computed tomography (CT) system, then the tag readily appears because you can choose materials with different densities for the “taggant” and the part. For more information on this application, see our paper with Sharon Flank and her team at InfraTrac Inc. in 3D Printing and Additive Manufacturing.

We tend to only focus on the positive benefits of AM, but counterfeit parts are becoming easier and easier to make thanks to AM. Aerospace and defense companies are spending billions of dollars to ensure fake parts do not enter their respective supply chains. Luckily, we can use the design and material freedoms of DED to help us solve some of those issues, too.

Related Content

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read MoreRead Next

What Is Directed Energy Deposition?

Analyzing directed energy deposition and powder-bed fusion provides a thorough understanding of the extra machining necessary for a “near-net shape” versus a “net shape” manufacturing process.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More