Inert Gas in Metal 3D Printing, Materials and Postprocessing

High-end metal additive manufacturing relies on the perfect gas composition to create products that meet the required material properties. But gas such as argon is also key to metal powder production, storage and postprocessing.

One of the major challenges in metal additive manufacturing (AM) is the need to build components in a controlled environment and minimize the introduction of any possible impurities into the materials. Inert gases such as argon and nitrogen create an environment which is inert, i.e. chemically inactive, which allows parts to be built which meet the exacting standards required for metal parts used in the aerospace and automotive industries.

In an inert atmosphere AM processes such as directed energy deposition, electron beam melting, selective laser sintering, binder jetting or powder bed fusion can take place without the risk of contamination from reactive gases that exist in the air, such as oxygen and carbon dioxide.

Inert gas plays a pivotal role in producing high-quality metal AM parts—not only for the print process in the inert atmosphere where impurities need to be avoided (1). Inert gas is also essential for pre- and post-production processes such as metal powder production and storage (2) and postprocessing (3).

1. Overcoming Atmospheric Impurities

As is well understood, the core powder-based AM process is shielded by or takes place within a closed chamber filled with high-purity inert gases such as argon and nitrogen. What is less well understood is that even after the atmosphere is purged between build cycles, impurities can remain present in the chamber due to incomplete purging or via access through loose connections or the metal powder itself.

Even extremely small variations in oxygen content can impair the mechanical or chemical properties of alloys sensitive to oxygen like titanium or aluminum and can affect the composition of the end product, resulting in negative physical characteristics such as discoloration and even poor fatigue resistance. For industries at the forefront of AM adoption such as aerospace, automotive and medical, such negative production outcomes are critically important to avoid.

Linde Gases has dedicated the past three years to developing pioneering technology to overcome these atmospheric impurities in order to give manufacturers optimum printing conditions. The result is an oxygen measuring technology called “ADDvance O2 precision,” which provides continuous analysis of the gas atmosphere, detecting oxygen levels with high precision without cross-sensitivity.

Recognizing O2 concentrations as low as 10 parts per million (ppm), the unit automatically initiates a purging process to maintain the atmosphere as pure as needed. The technology is already in use at companies at the vanguard of AM including Liebherr Aerospace in France, Gefertec GmbH, leading car manufacturers in Germany as well as other partners, both industrial and academic.

2. Metal Powder Production and Storage

The mechanical properties of a finished product are not only highly dependent upon the AM process itself, but the characteristics of the powder used in that process. The quality of metal powders used in AM is critically important as it can impact the physical properties of the finished product, including tensile strength, brittleness, impact resistance, heat tolerance and resistance to corrosion. Powder quality also plays a vital part in consistency and production repeatability—a key focus area for AM which looks to ultimately apply stringent uniformity for more series-based production. Atmospheric gases play an essential role in the delivery of the necessary powder quality.

High sphericity of the metal particles is needed so that the metal powder flows smoothly and evenly inside the 3D printer. High powder layer density is also required to produce dense parts with high scan velocities, resulting in high productivity. The density of a powder layer is particularly dependent on particle shape and size, as well as size distribution. Particle shape influences porosity because the greater a deviation from a spherical shape leads to a lower density, and therefore more porosity. Additionally, a spherical shape also offers better flow properties during recoating.

Gas atomization is the most effective approach to metal powder production due to the superior geometrical properties that can be achieved. It requires not only a large supply of inert gases such as argon and nitrogen, but the gas molecule expertise to help manufacturers fine tune the atomization process to further improve powder characteristics and eliminate rejects—and to do so cost effectively.

The Powder Storage Challenge

Once the metal powders have been produced, it is essential to maintain the correct atmosphere during storage in order to avoid humidity. The quality of metal powder has a fundamental impact on the microstructure and physical properties of the 3D-printed item, so it must be of a defined and consistent quality, meaning that correct storage and handling is vital. Humidity will age the powder, reduce its flowability and will increase the amount of O2 during printing.

Metal powders are typically stored in containers or closed cabinets in the vicinity of the printer until needed. However, with each opening of the vessel ambient air and humidity is allowed to enter, affecting the chemical and physical characteristics of the powder and causing it to age. When stored in cabinets, the powder can react with the atmosphere within the cabinet itself. Even if the cabinet is purged, ambient air and humidity flow in each time the doors are opened resulting in contamination and degradation.

Linde offers the ADDvance powder cabinet to resolve this storage challenge. The powder cabinet works with a moisture control and monitoring unit to continuously measure humidity levels, triggering a high-volume purge gas flow as soon as the doors are closed to rapidly remove moisture in the air. It then applies a lower stream of gas to ensure a consistently low level of humidity, ensuring the quality of the valuable, sensitive metal powders is retained.

3. Postprocessing: The Final Touch

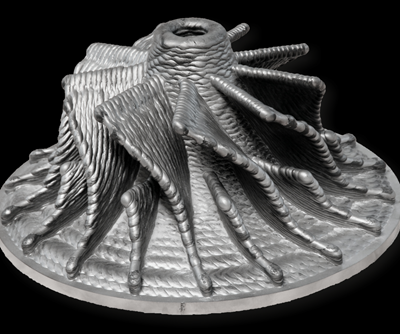

Most AM components require a heat treatment step to reduce stress. Hot isostatic pressing (HIP) is an advanced material heat treatment process utilizing elevated temperatures in a contained high-pressure atmosphere to eliminate internal porosity and voids within cast metal materials and components. The workpieces are treated thermally in a vessel under high isostatic pressure with high-purity argon typically used to provide the inert atmosphere necessary to prevent chemical reactions that might adversely affect the materials being treated.

The smallest impurity in the argon will at this pressure—easily up to 1,000 bars—create oxidation. This is a key challenge for the gas supply. Under the high temperature/high pressure HIP process conditions, microporosity and voids are reduced or eliminated by plastic deformation, creep and diffusion bonding, improving mechanical properties and fatigue performance of manufactured parts. The reliability and service life of critical high‑performance components are optimized. Typical HIP applications include gas turbine components, automotive engine parts, turbocharger wheels, aerospace structural parts, medical implants, prosthetics and near-net-shape components.

Inert gas such as argon or even a special reactive gas mixture including some hydrogen or methane is also needed for sintering process in binder jetting. Binder jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles and is applied in alternate layers with the material to be bonded. The build is done under air and once completed, the object separated from the build plate—called a “green component”—has poor mechanical strength and high porosity. This can be rectified by the sintering process, with the part being fed slowly through a special high-temperature furnace under inert gas to bond the metal particles together.

Surface Finishing

During any of the AM processes, blast powder residue or unfused powder can build up on the part being printed. Removing particles from holes and cavities can represent a particular challenge in the case of small, elaborate parts and components with complex geometries, especially as melting metal residue requires potentially damaging high temperatures. Depending on the application in question, a number of different surface finishing treatments can be applied to remove or reduce the surface roughness of AM parts including barrel finishing, abrasive flow machining, plasma polishing, micromachining, electrochemical polishing, and cryogenic cleaning or dry ice blasting.

Cryoclean technology creates dry ice particles, or “snow,” by expanding liquid CO₂ and using compressed air to accelerate the particles up to sonic speed, shooting them onto the surface to be cleaned. The cleaning effect relies on flash cooling, kinetic energy, embrittlement and gas impact. If needed, a further abrasive agent can be added to the dry ice particles to remove more stubborn powder residue.

About the Author

Pierre Forêt, Senior Expert Additive Manufacturing, Linde

Pierre Forêt is Senior Expert, Additive Manufacturing at Linde. Linde Gases Division is known as a leading gas and application provider for all additive manufacturing processes. Learn more at linde-gas.com/am.

Related Content

BPMI Chooses Velo3D Metal 3D Printing System to Produce Parts for U.S. Naval Nuclear Propulsion Program

The fully integrated 3D printing solution will be operated by ATI in a newly established facility that will provide the U.S. Naval Nuclear Propulsion Program with alternatives to cast parts.

Read More8 Transformations 3D Printing Is Making Possible

Additive manufacturing changes every space it touches; progress can be tracked by looking for moments of transformation. Here are 8 places where 3D printing is enabling transformative change.

Read MoreHeat Exchangers 3D Printed from Haynes Alloy: The Cool Parts Show Bonus

Heat exchangers used in concentrated solar power must withstand elevated temperatures and pressures, and 3D printing enables the use of materials appropriate to this application.

Read MoreConocoPhillips Sees Oil and Gas Supply Chain Opportunity With Additive Manufacturing

Production of parts when needed and where needed can respond to the oil and gas sector’s multibillion-dollar challenge of holding parts in inventory. The supply chain benefit will justify additive even before the design freedoms are explored.

Read MoreRead Next

Gefertec, Linde Partner on Additive 3DMP Research

Gefertec and Linde have partnered with two other companies to research Gefertec’s 3DMP 3D printing process and ultimately determine what gas and oxygen percentage needs to be used to optimize high-production of larger titanium alloy parts.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More

.JPG;width=700;quality=80)

.png;width=860)

.JPG;width=860)

.jpg;width=860)