Digital Metal Achieves UL Certification

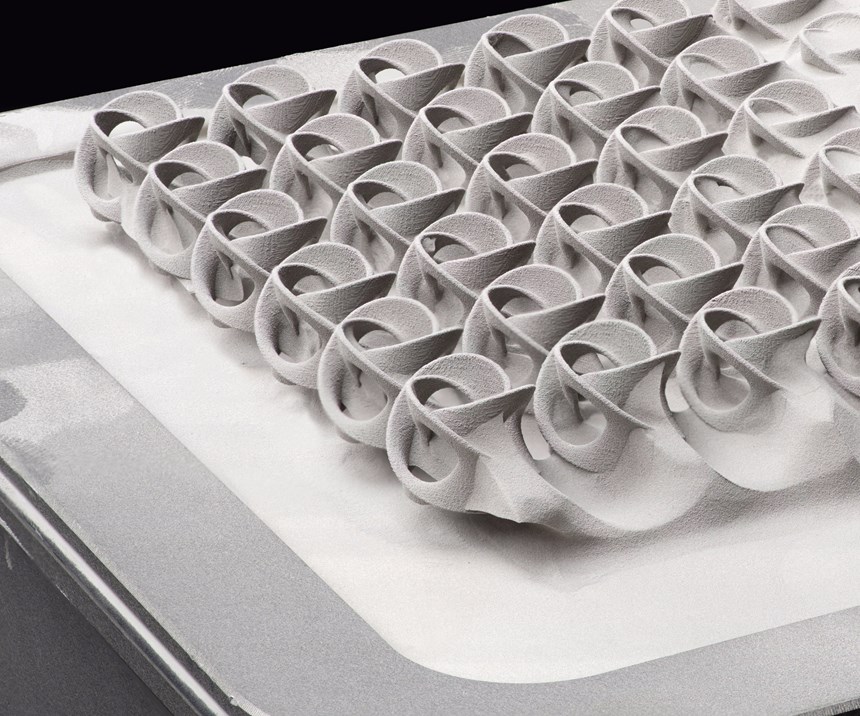

Digital Metal has been authorized to apply the Underwriters Laboratories (UL) mark to its DM P2500 metal binder jetting system, the first such system to receive the UL certification.

Digital Metal, a Höganäs Group company, has completed product testing and achieved authorization to apply the Underwriters Laboratories (UL) mark to its DM P2500 metal binder jetting system. UL is a global not-for-profit product safety testing and certification organization.

The technical team at Digital Metal addressed the requirements for both UL and CE certification in the concept stages for the DM P2500, proving that the printer meets standards for U.S. and Canadian markets. Preparation for meeting these standards is involved in all steps of developing and designing a new machine, the company says. Each component and system in the machine must be taken into account. The engineering time invested to meet these demands is well spent, the company says. Not only do the standards ensure machine safety, they also contribute to improved working environments.

DM P2500 is the first metal binder jetting system to receive UL certification, the company says.

“Employee and customer safety should be the number one priority for every business owner. It is crucial that the equipment you use on a regular basis is working properly and more importantly, that it is manufactured and installed correctly. The UL certification is an important way to ensure that,” says Ralf Carlström, general manager at Digital Metal.

Related Content

-

AMGTA Research Demonstrates Sustainable Benefits of Binder Jet 3D Printing

Research from the Yale School of the Environment shows substantial reduction in GHG over traditional casting methods.

-

Freeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

-

Binder Jetting Vs. Metal Injection Molding: The Cool Parts Show All Access

Alpha Precision Group, provider of both processes, discusses considerations that go into making this choice.