Medical & Dental

Rivelin Robotics Leads Project CAMPFIRE to Develop Automated Postprocessing Solutions for Regulated Industries

The participating companies are working to create complete digital postprocessing solutions for the automated finishing of flight parts, orthopedic implants and gas turbine components produced using metal additive manufacturing processes.

Read MoreBMF Receives FDA Clearance for UltraThineer Dental Veneer Material

The zirconia materials are now qualified for use in the production of the world’s thinnest cosmetic veneers, which require significantly less tooth preparation or grinding, thereby preserving more of the patient’s natural enamel.

Read MoreFormlabs’ Form 4 3D Printer Offers New Levels of Reliability and Speed for Stereolithography

The Form 4 is designed to deliver most parts in less than two hours, offering users a powerful, affordable tool to bring ideas to life at fast speeds with excellent reliability, print quality and ease of use.

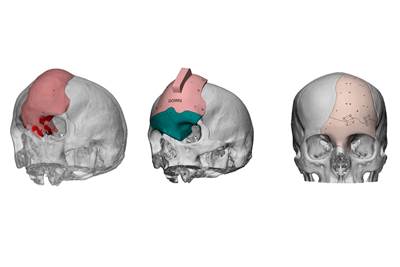

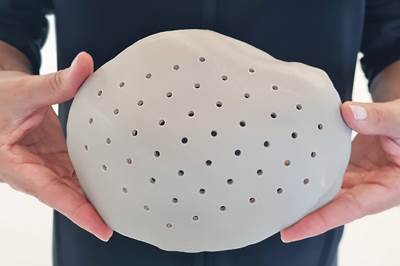

Read MoreArcomedLab Utilizes Biomedical 3D Printing for 700 Successful Craniomaxilofacial Implants in Latin America

The company specializes in biomedical 3D printing with a focus on patient-centric solutions.

Read More3D Systems Receives FDA Clearance for World’s First 3D Printed PEEK Cranial Implants

The FDA clearance now enables widespread adoption of 3D Systems’ self-contained, cleanroom environment-based printing system, the EXT 220 MED, with medical-grade PEEK materials to deliver patient-specific cranial reconstruction solutions.

Read MoreUltra-Complex 3D Printed Scaffolds Enable Cell Growth: The Cool Parts Show #70

Perhaps the ultimate surface-area challenge is in bioengineering: creating structures that can grow sufficient cells within a compact volume to be effective for leading-edge medical treatments. The Southwest Research Institute develops bioreactor scaffolds that could only be made using 3D printing.

Watch4 Weeks from Design to Molded Part for Medical with Metal 3D Printed Tooling

Mold builder Westminster Tool applied the Trueshape process from Mantle to produce tooling to take a medical device from prototype mold to full-scale production in a matter of weeks.

Read MoreGPAInnova America Partners With Xact Metal for Complete Dental 3D Printing Process

The collaboration involves the utilization of GPAInnova’s DryLyte electropolishing technology as a postprocessing solution for Xact Metal’s metal 3D printers.

Read MoreAddUp and Anatomic Implants Collaborate on FDA Submission for 3D Printed Toe Joint Replacement

Anatomic Implants has chosen to use AddUp’s FormUp 350 Powder Bed Fusion machine to qualify the implant for submission to the FDA. The FormUp 350 is able to produce varying complex geometries with fine detailed lattice structures, which are well suited for implantable medical devices.

Read MoreCollaboration Provides Scalable Efficiency, Quality, Traceability for Dental Laboratories

The collaboration combines the expertise of Axtra3D and Oqton to enable higher quality dental solutions as well as production automation and fleet management for various applications, including connectors and direct print manufacturing.

Read More