3D Systems Receives FDA Clearance for World’s First 3D Printed PEEK Cranial Implants

The FDA clearance now enables widespread adoption of 3D Systems’ self-contained, cleanroom environment-based printing system, the EXT 220 MED, with medical-grade PEEK materials to deliver patient-specific cranial reconstruction solutions.

Share

Read Next

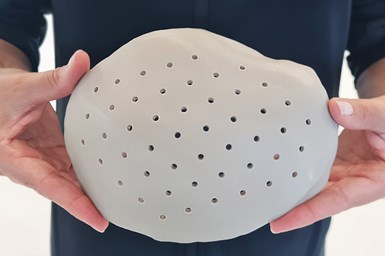

3D Systems has received the Food and Drug Administration’s (FDA) 510(k) clearance for the company’s 3D printed, patient-specific cranial implant solution — the VSP PEEK Cranial Implant. The VSP PEEK Cranial Implant includes a complete FDA-cleared workflow comprising segmentation and 3D modeling software, the 3D Systems EXT 220 MED 3D printer, Evonik VESTAKEEP i4 3DF PEEK (polyetheretherketone) and a predefined production process.

By utilizing additive manufacturing (AM) solutions, the company says this technology can produce patient-specific cranial implants with up to 85% less material than similar implants produced by traditional machining, which can lead to significant cost savings for an expensive raw material like implantable PEEK. Also, the cleanroom-based architecture of the printer combined with simplified postprocessing workflows makes the technology well suited for producing patient-specific medical devices at the hospital site with faster turnaround while keeping the overall cost under control.

To date, this solution has been used to enable nearly 40 successful cranioplasties in Switzerland at University Hospital Basel, in Austria at Salzburg University Hospital and in Israel at Tel-Aviv Sourasky Medical Center.

“3D-printed PEEK cranial plates are an innovative solution that can improve patient care and expand the possibilities for precise, individualized neurosurgery,” says Dr. Johannes Pöppe, senior attending surgeon, department of neurosurgery, University Hospital Salzburg. “The solution is revolutionizing the field. The combination of 3D Systems’ printing technology that is uniquely engineered for sterile environments along with the mechanical properties of PEEK are helping surgeons push boundaries. Within our hospital, we have already completed several successful surgeries using these technologies. I believe the potential for customized PEEK cranial plates is significant to integrate 3D printing into routine clinical practice.”

The VSP PEEK Cranial Implant is the first FDA-cleared, additively manufactured PEEK implant intended for cranioplasty procedures to restore defects in the skull. This implant-grade, high-performance polymer has a well-known clinical history in medical device applications due to its exceptional performance with mechanical properties closely mirroring human bone. In addition, PEEK has excellent biocompatibility, resistance to bodily fluids and stability in a wide range of temperatures, making it well suited for many medical device applications. Also, its inherent radiolucency is said to ensure minimal interference in medical imaging, facilitating a clearer evaluation of the surgical site and implant integrity.

“As a leader in medical device innovation, 3D Systems prides itself on pioneering advancements that benefit both surgeons and patients,” says Dr. Gautam Gupta, SVP and general manager, medical devices, 3D Systems. “Receiving FDA clearance for our VSP PEEK Cranial Implant solution is a significant milestone in our journey. Our EXT 220 MED printing system has already enabled the production of nearly 40 cranial implants in support of successful cranioplasties throughout Europe. With this FDA clearance, we are now able to bring VSP PEEK Cranial Implant to the U.S. — setting a new standard of excellence for these procedures. We are now looking to the next applications for this technology, which includes 3D-printed spine interbody fusion implants, carbon fiber-reinforced PEEK for plating applications in trauma and fixation, and bioresorbable polymers for large bone and craniomaxillofacial applications.”

3D Systems has worked with surgeons for more than a decade to plan more than 150,000 patient-specific cases and manufacture more than 2 million implants and instruments for 100-plus CE- marked and FDA-cleared devices from its FDA-registered, ISO 13485-certified facilities in Littleton, Colorado, and Leuven, Belgium.

This FDA clearance enables 3D Systems to expand its PEEK product portfolio through the EXT 220 MED platform. With this milestone, the company is not just introducing a pioneering product it is setting the stage for a comprehensive range of advanced PEEK-based solutions designed to meet the diverse needs of the medical field. 3D Systems says its experience in developing patient-specific, high-performance PEEK implants, combined with its database, places the company in a good position to accelerate the development process.

The company says that its expertise that can offer existing customers and partners an expedited pathway to bring their products to market. By leveraging 3D Systems’ track record and the capabilities of the EXT 220 MED platform, the company can supporting its partners in navigating the regulatory landscape more efficiently, ensuring faster access to innovative medical solutions that enhance patient care and outcomes.

Cranial implants can address a breadth of applications, including trauma, defects and reconstruction. The continued innovation in materials and manufacturing methodologies such as 3D printing are expected to enable new solutions to foster growth in this market.

Related Content

3D Printed PEEK Spine Implants in Production: The Cool Parts Show Bonus

Curiteva is using Fused Strand Deposition to produce two different lines of FDA-cleared spine implants. We visited the company’s Huntsville, Alabama, facility to learn more.

Read MoreOvercoming Challenges with 3D Printing Nitinol (and Other Oxygen-Sensitive Alloys) Through Atmospheric Control

3D printed nitinol has potential applications in dental, medical and more but oxygen pickup can make this material challenging to process. Linde shares how atmospheric monitoring and the use of special gas mixtures can help maintain the correct atmosphere for printing this shape alloy and other metals.

Read MoreFDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More